A kind of carbon block fixing method and device for continuous prebaked anode

A technology of anode carbon block and pre-baked anode, which is applied in the field of carbon block fixing method and device for continuous pre-baked anode, can solve the problems of increasing power consumption rate, affecting current efficiency, increasing heat loss, etc., and improving sintering The effect of stability, excellent mechanical strength and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

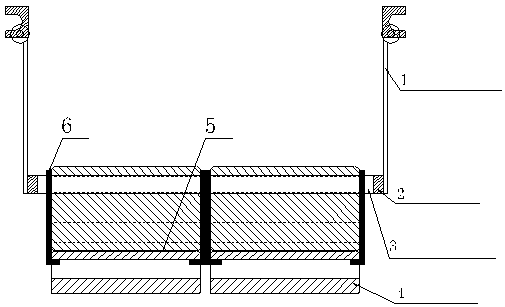

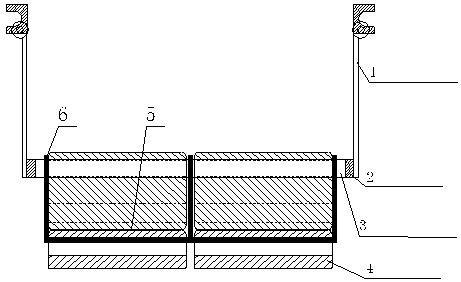

[0015] Example 1. A carbon block fixing device for continuous prebaked anodes, comprising an anode carbon block 4 being electrolyzed and a new anode carbon block 4 placed above, and a bonding layer 5 is coated between the upper and lower anode carbon blocks 4 .

[0016] The aforesaid carbon block fixing device for continuous prebaked anodes, the anode carbon block 4 is provided with a through groove, the through groove passes through the load-bearing conductive beam 3, and the load-bearing conductive beam 3 is connected to the lifting device through the joint solid cross arm 2 1. The load-bearing conductive beam 3 of the upper anode carbon block 4 is connected to the auxiliary hook 6, and the lower part of the auxiliary hook 6 is inserted into the through groove of the lower anode carbon block 4. auxiliary hook 6 as figure 1 and 2 As shown, it can be L-shaped, or integral.

[0017] The adhesive layer 5 includes an adhesive and a conductive paste. The adhesive layer 5 includ...

Embodiment 2

[0021] Embodiment 2: The adhesive layer 5 includes an adhesive and a conductive paste, the adhesive is composed of 15 parts of pitch and 85 parts of graphite powder, and the conductive paste is composed of 10 parts of tar and 90 parts of aluminum powder.

Embodiment 3

[0022] Embodiment 3: The adhesive layer 5 includes an adhesive and a conductive paste, the adhesive is composed of 12 parts of pitch and 88 parts of graphite powder, and the conductive paste is composed of 13 parts of tar and 87 parts of aluminum powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com