Baking process method for reducing release amount of benzopyrene in flue-cured tobacco

A curing process and benzopyrene technology, which are applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problem that the release amount is not paid attention to, and achieve the effects of improving the economic value of tobacco leaves, reducing the release amount, and improving the sensory quality of tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Test tobacco leaves: the upper leaves, the 14th to 16th leaves.

[0029] The tobacco leaves obtained by roasting according to the process conditions in Table 1 were used as control samples, and the tobacco leaves obtained by roasting according to the process conditions in Table 2 were used as test samples.

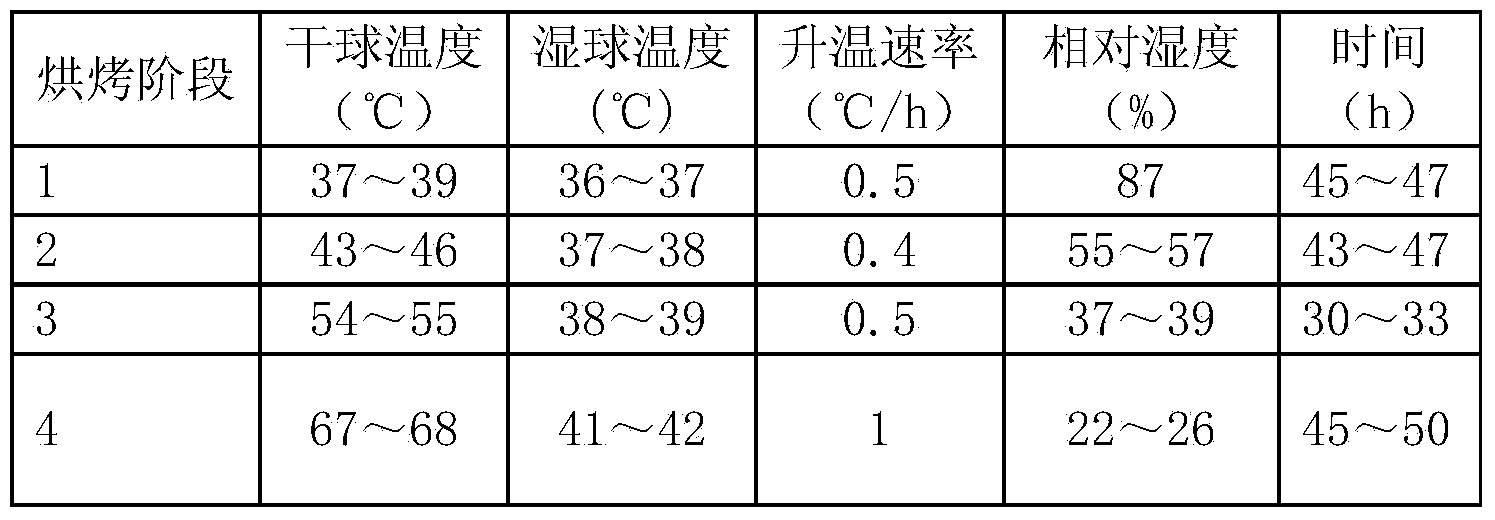

[0030] Table 1 Existing baking process parameter list

[0031]

[0032] Note: the upper, middle and lower tobacco leaves in the existing curing process all use the process parameters in Table 1.

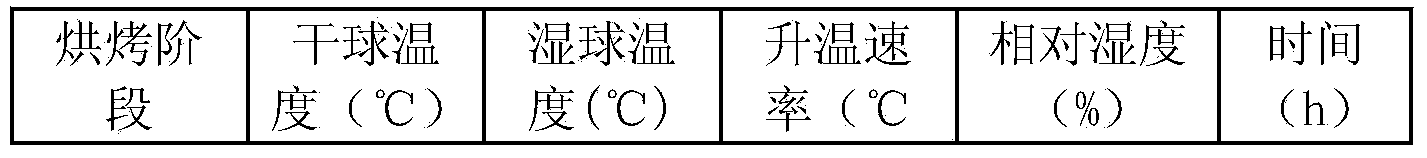

[0033] Table 2 Test baking parameters

[0034]

[0035]

[0036] See Table 3 for the detection results of the benzopyrene emission from the tobacco leaves of the control sample and the tobacco leaves of the test sample.

[0037] The detection result of the release amount of benzopyrene in the samples after table 3 roasting

[0038]

[0039] As can be seen from Table 3, the technology provided by the present invention has an obvious reduction effect on the re...

Embodiment 2

[0053] Test tobacco leaves: the upper leaves, the 14th to 16th leaves.

[0054] The test was carried out according to the method of Example 1. The existing baking process parameters are shown in Table 1, and the setting of the test baking process parameters is shown in Table 7.

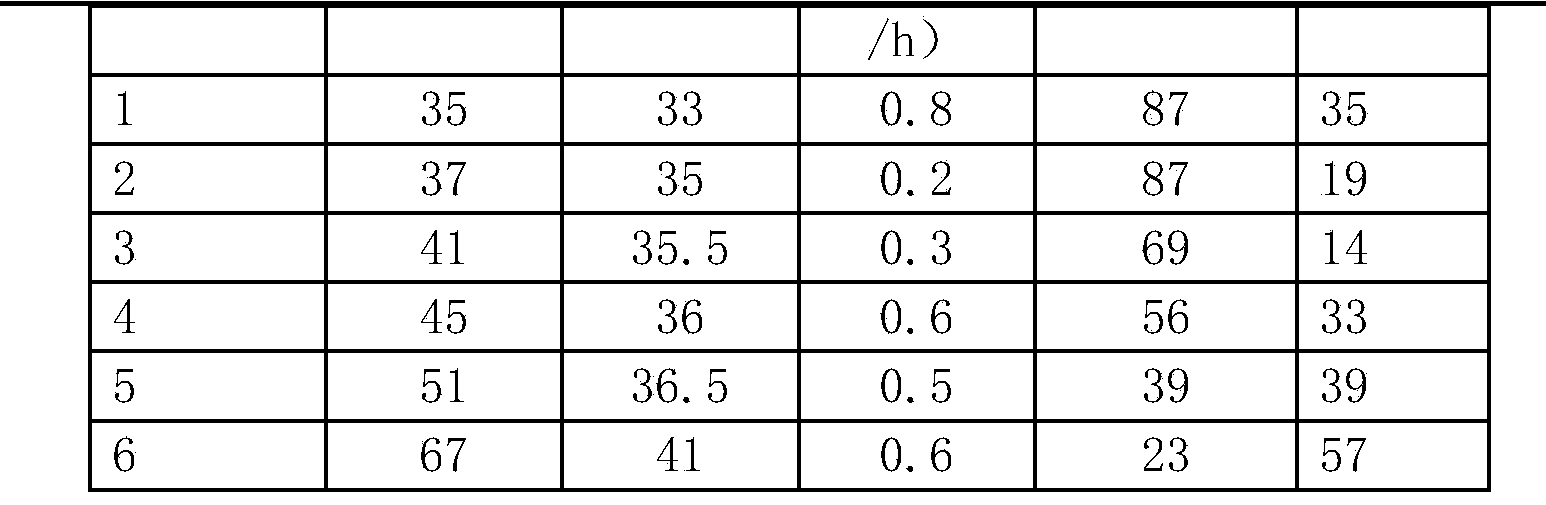

[0055] Table 7 test baking parameters

[0056]

[0057]

[0058] See Table 8 for the test results of the release of benzopyrene from the tobacco leaves of the test samples.

[0059] The detection result of the sample benzopyrene release amount after table 8 bakes

[0060]

[0061] As can be seen from Table 8, the process provided by the present invention has an obvious reduction effect on the release of benzopyrene. Compared with the existing baking process, the release of benzopyrene is reduced from 11.1ng / g to 8.6ng / g, and the drop reaches 22.5 ng / g. %.

[0062] The appearance quality of the cured tobacco leaves was evaluated, and the cured whole kang tobacco leaf samples were graded accor...

Embodiment 3

[0075] Test tobacco leaves: the middle leaves, the 9th to 11th leaves.

[0076] The test was carried out according to the method of Example 1. The existing baking process parameters are shown in Table 1, and the setting of the test baking process parameters is shown in Table 12.

[0077] Table 12 test baking parameters

[0078]

[0079]

[0080] After the tobacco leaves are cured according to the parameters in Table 12, measure the benzopyrene emission of the test tobacco leaves and the reference tobacco leaves, carry out the grade structure classification of the tobacco leaves, the sensory quality evaluation and smoking and the tobacco leaf purchase pricing, the results are consistent with the trends of Examples 1 and 2 Same, all show, each index of test tobacco leaf is all better than comparison tobacco leaf.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com