A niobium-doped lithium-rich manganese-based layered oxide cathode material and a preparation method thereof

A technology of lithium-rich positive electrode materials and positive electrode materials, applied in the field of electrochemistry, can solve problems such as poor charge and discharge rate performance, low Coulombic efficiency, etc. effect of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

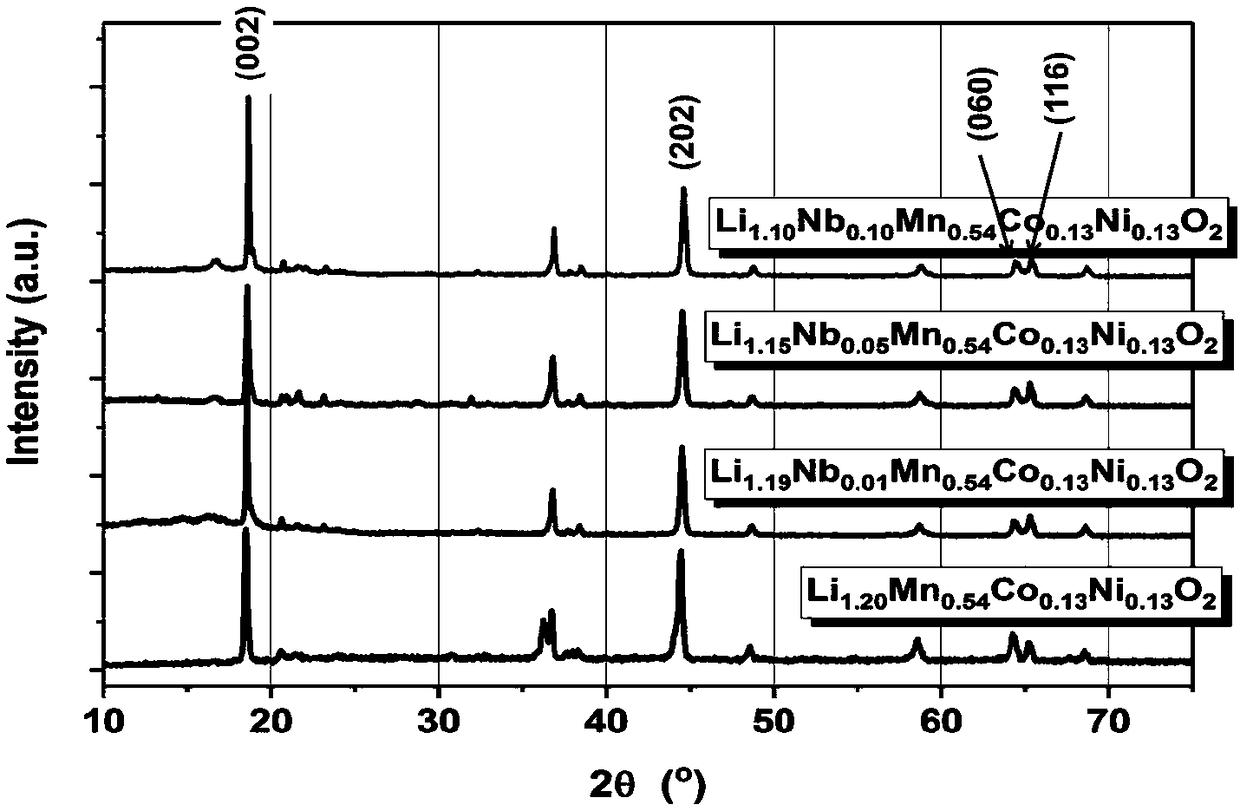

Embodiment 1

[0054] Step 1: Add 300mL cyclohexane, 1.93g sorbitan monostearate (Span-60), and 2.1mL octylphenol polyoxyethylene ether (OP-10) into a 500mL four-port container equipped with a mechanical stirring device Keep it in the bottle at 27°C and stir evenly under nitrogen protection to obtain the oil phase. Then 20mL of 6mol / L acrylamide+methacrylic acid solution (AA:MAA=9:1 molar ratio), which contains 0.15g vinylpyrrolidone (PVP), 0.15g N,N'-methylenebisacrylamide , 0.40 g of ammonium persulfate (APS), and 0.48 g of sodium hydroxide (NaOH) were prepared into the water phase, added to the above oil phase, protected by nitrogen gas, and stirred for 0.5 h. Dissolve 0.24mL of N,N,N',N'-tetramethylethylenediamine in 45mL of cyclohexane, and slowly drop it into a four-neck flask for 2 hours, then keep the temperature at 27°C and stir for 24 hours. The product is alternately washed with water and acetone for several times to remove unreacted monomers and oligomers, and the washed product...

Embodiment 2

[0058] According to the method of Example 1, without adding niobium acetate, the lithium-rich manganese-based positive electrode material Li without doping niobium was synthesized. 1.20 mn 0.54 co 0.13 Ni 0.13 o 2 .

Embodiment 3

[0060] According to the method of Example 1, 0.001mol of niobium acetate was added to synthesize the lithium-rich manganese-based layered positive electrode material Li 1.19 Nb 0.01 mn 0.54 co 0.13 Ni 0.13 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com