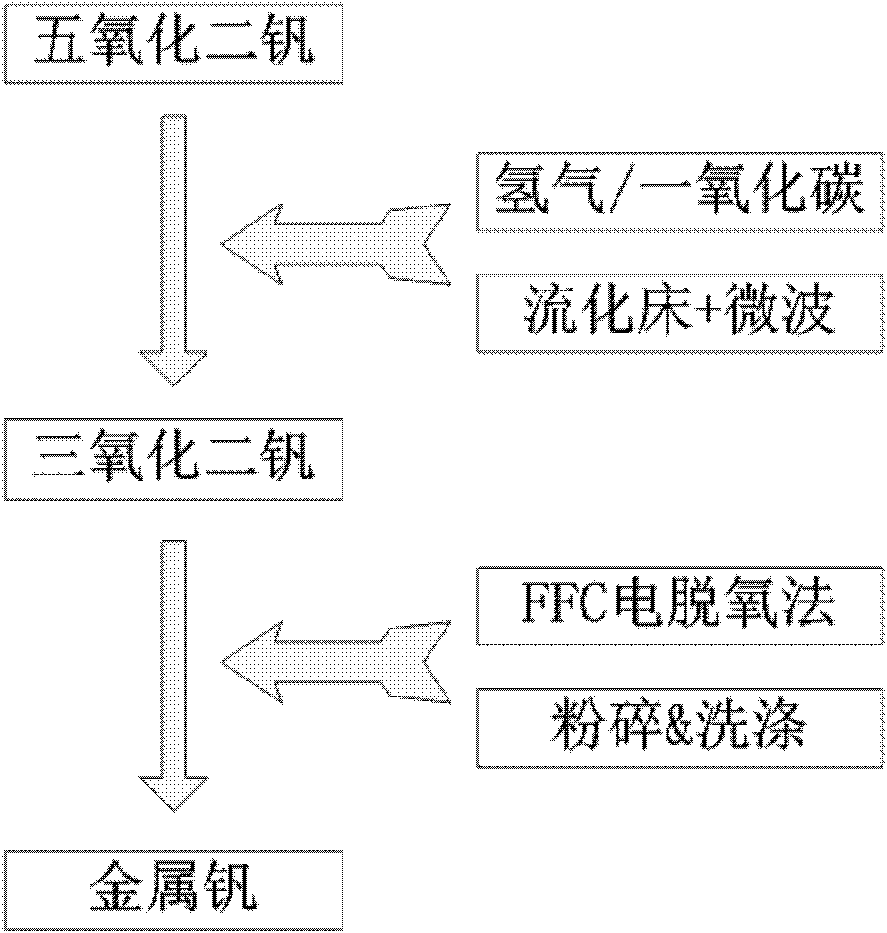

Vanadium metal smelting process

A metal and process technology, applied in the new metallurgical technology field, can solve the problems of unsuitable temperature requirements, large temperature control deviation of the heated body, reaction control, etc., and achieve the effects of heat concentration, high energy utilization rate, and fast heating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

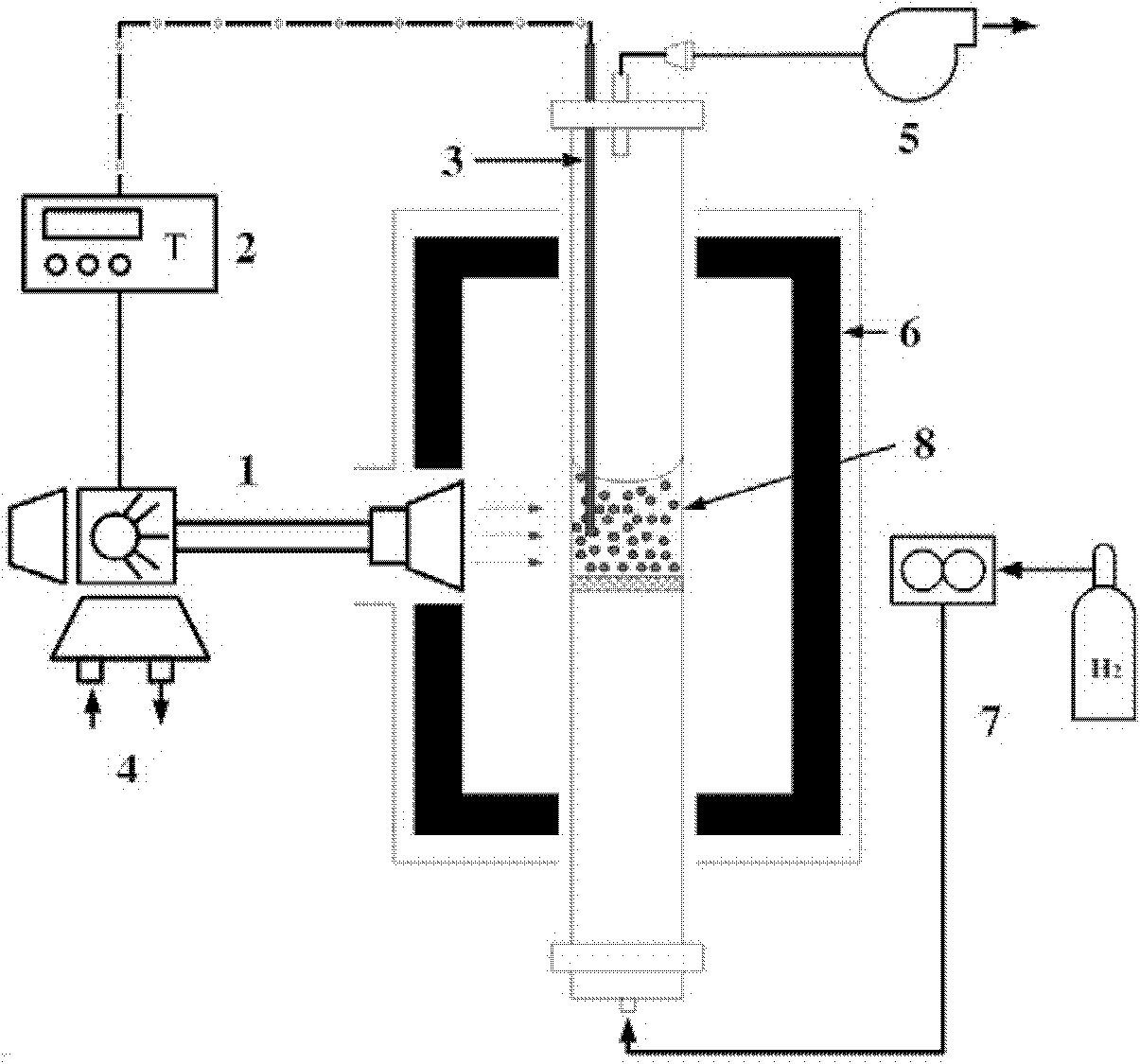

Method used

Image

Examples

example 1

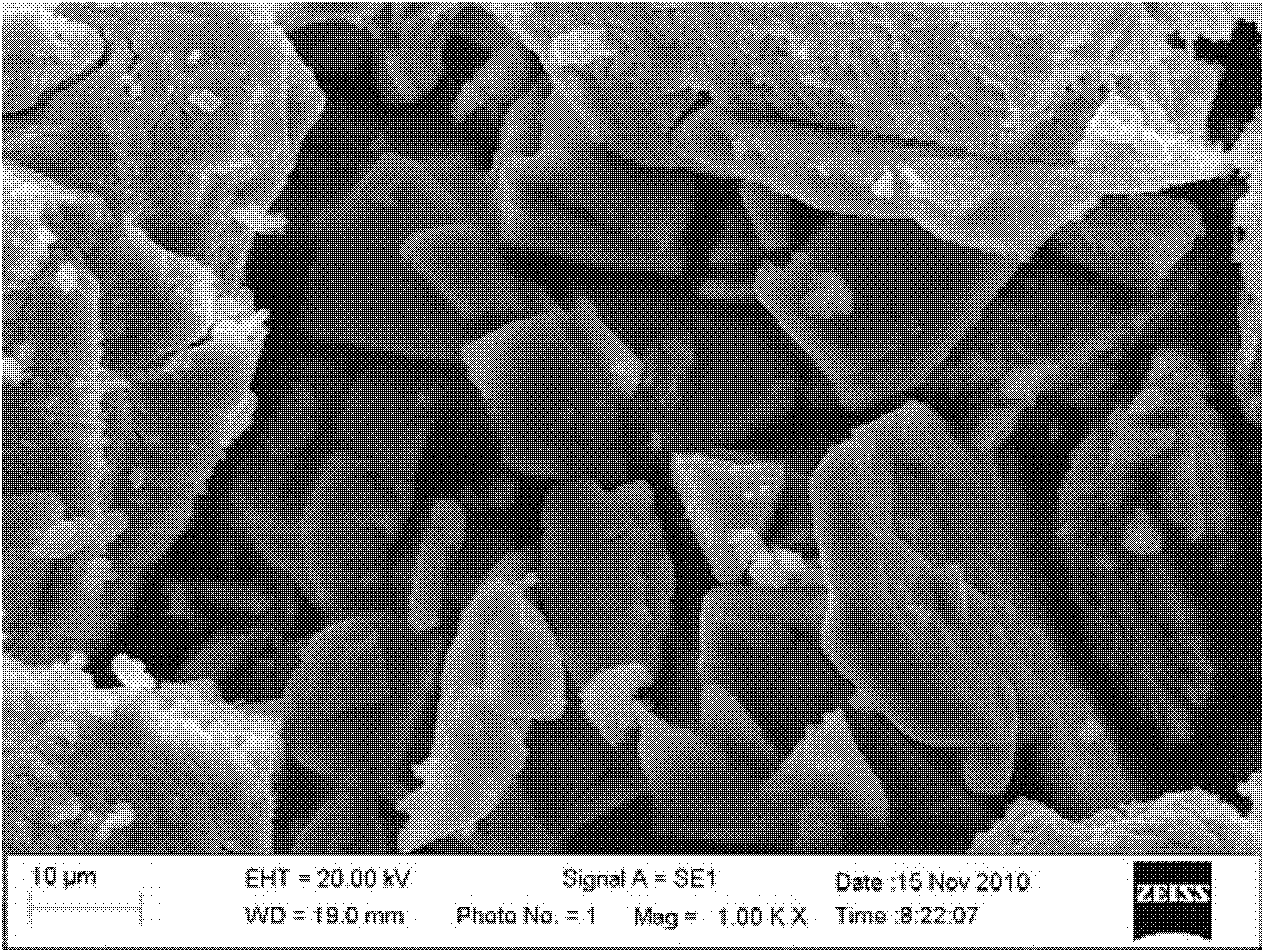

[0030] Take 1000g vanadium pentoxide refined powder (purity ≥99%), put it on the fluidized bed distribution plate, bubbling in nitrogen for 10 minutes (10L / min) and start heating up (heating rate=100℃ / min). Control the microwave heating equipment to keep the temperature constant at 650°C, introduce reducing gas carbon monoxide at 10L / min, turn on the exhaust device to exhaust the tail gas, and maintain the pressure difference between the upper and lower sides of the distribution plate at 30KPa. After 30 minutes of reduction, close the reduction gas circuit and exhaust gas circuit, and cool down to below 100°C steadily. Phase analysis of the obtained product showed that it was basically purple-black vanadium trioxide powder, which contained a small amount of vanadium dioxide. The utilization rate of reducing gas carbon monoxide is 79%.

[0031] The reduced vanadium trioxide powder is mixed with 5% polyvinyl alcohol (PVA) aqueous solution, and the mixing mass ratio is controlled t...

example 2

[0033] Take 1000g vanadium pentoxide refined powder (purity ≥99%), put it on the fluidized bed distribution plate, bubbling in nitrogen for 10 minutes (10L / min) and start heating up (heating rate=100℃ / min). Control the microwave heating equipment to keep the temperature constant at 650°C, pass in the reducing gas hydrogen at 10L / min, open the exhaust device to exhaust the tail gas, and maintain the pressure difference between the upper and lower sides of the distribution plate at 35KPa. After 30 minutes of reduction, close the reduction gas circuit and exhaust gas circuit, and cool down to below 100°C steadily. Phase analysis of the obtained product showed that it was basically purple-black vanadium trioxide powder. The utilization rate of reducing gas hydrogen is 83%.

[0034] The reduced vanadium trioxide powder is mixed with 5% polyvinyl alcohol (PVA) aqueous solution, and the mixing mass ratio is controlled to 10%. After stirring evenly, batches are pressed into Φ40mm*10mm d...

example 3

[0036] Take 1000g vanadium pentoxide refined powder (purity ≥99%), put it on the fluidized bed distribution plate, bubbling in nitrogen for 10 minutes (10L / min) and start to heat up (heating rate ≥50°C / min). Control the microwave heating equipment to keep the temperature constant at 600°C, introduce reducing gas carbon monoxide at 10L / min, turn on the exhaust device to discharge the tail gas, and maintain the pressure difference between the upper and lower sides of the distribution plate at 40KPa. After 30 minutes of reduction, close the reduction gas circuit and exhaust gas circuit, and cool down to below 100°C steadily. Phase analysis of the obtained product showed that it was basically purple-black vanadium trioxide powder. The utilization rate of reducing gas carbon monoxide is 82%.

[0037] The reduced vanadium trioxide powder is mixed with 5% polyvinyl alcohol (PVA) aqueous solution, and the mixing mass ratio is controlled to 10%. After stirring evenly, batches are pressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com