Adsorption pad for tft thinning and polishing

A technology for thinning polishing and adsorption pads, applied in layered products, synthetic resin layered products, grinding tools, etc., can solve the problems of long hydrophobic chains, low water solubility, high surface activity, etc., to slow down rapid penetration and avoid The effect of high water absorption and excellent damping and anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

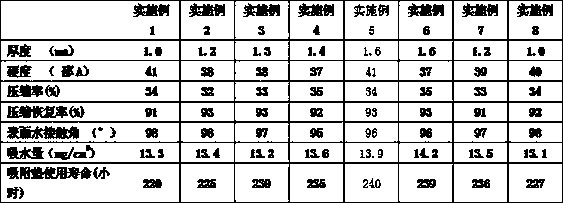

Embodiment 1

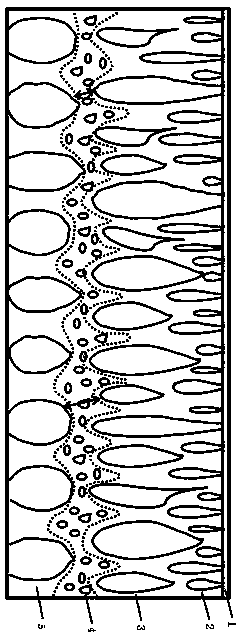

[0062] An adsorption pad for TFT thinning and polishing, the adsorption pad is provided with release paper, double-sided tape, PET film, double-sided tape, fluorine-containing polyurethane porous film and protective film in sequence from bottom to top; the fluorine-containing polyurethane porous film From top to bottom are the surface adsorption layer 1, the first foam layer 2, the second foam layer 3, the third isolation layer 4 and the fourth foam layer 5, the surface adsorption layer 1 is a dense layer; the The first foamed layer 2 and the second foamed layer 3 are both water-drop-shaped porous structures, and the water-drop-shaped holes of the second foamed layer 3 are larger than the water-drop-shaped holes of the first foamed layer 2 .

[0063] The fourth foamed layer 5 is an oval porous structure with an average pore diameter of 200 μm, and the third isolation layer 4 is a reticulated pore structure formed by circular micropores with a pore diameter of 9-20 μm.

[0064]...

Embodiment 2

[0090] An adsorption pad for TFT thinning and polishing, the adsorption pad is provided with release paper, double-sided tape, PET film, double-sided tape, fluorine-containing polyurethane porous film and protective film in sequence from bottom to top; the fluorine-containing polyurethane porous film From top to bottom are the surface adsorption layer 1, the first foam layer 2, the second foam layer 3, the third isolation layer 4 and the fourth foam layer 5, the surface adsorption layer 1 is a dense layer; the The first foamed layer 2 and the second foamed layer 3 are both water-drop-shaped porous structures, and the water-drop-shaped holes of the second foamed layer 3 are larger than the water-drop-shaped holes of the first foamed layer 2 .

[0091] The fourth foamed layer 5 is an oval porous structure with an average pore diameter of 243 μm, and the third isolation layer 4 is a reticulated pore structure formed by circular micropores with a pore diameter of 4.2-17.8 μm.

[0...

Embodiment 3

[0118]An adsorption pad for TFT thinning and polishing, the adsorption pad is provided with release paper, double-sided tape, PET film, double-sided tape, fluorine-containing polyurethane porous film and protective film in sequence from bottom to top; the fluorine-containing polyurethane porous film From top to bottom are the surface adsorption layer 1, the first foam layer 2, the second foam layer 3, the third isolation layer 4 and the fourth foam layer 5, the surface adsorption layer 1 is a dense layer; the The first foamed layer 2 and the second foamed layer 3 are both water-drop-shaped porous structures, and the water-drop-shaped holes of the second foamed layer 3 are larger than the water-drop-shaped holes of the first foamed layer 2 .

[0119] The fourth foamed layer 5 is an oval porous structure with an average pore diameter of 205 μm, and the third isolation layer 4 is a reticulated pore structure formed by circular micropores with a pore diameter of 2-14.3 μm.

[0120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com