Textile printing and dyeing wastewater advanced treatment method

An advanced treatment, textile printing and dyeing technology, applied in water/sewage multi-stage treatment, electrochemical water/sewage treatment, water/sludge/sewage treatment, etc. The problem of high cost and high cost is achieved, and the effect of reducing the amount of alkali used in the process, low operating cost and short residence time is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

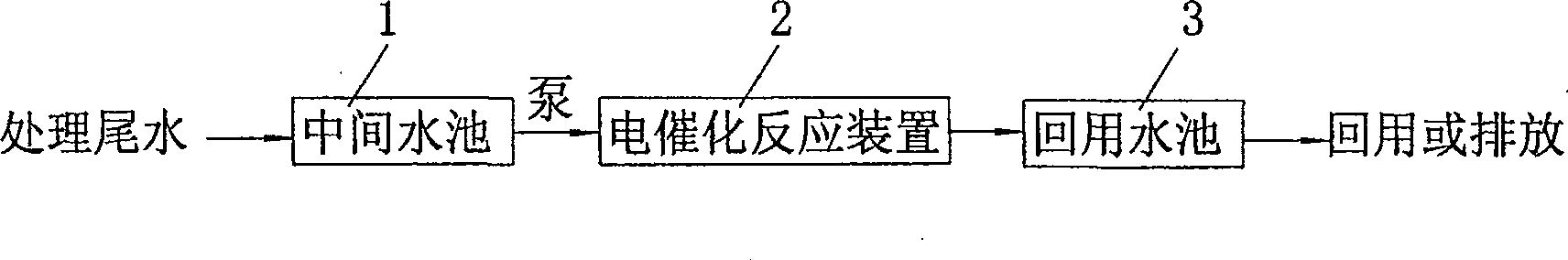

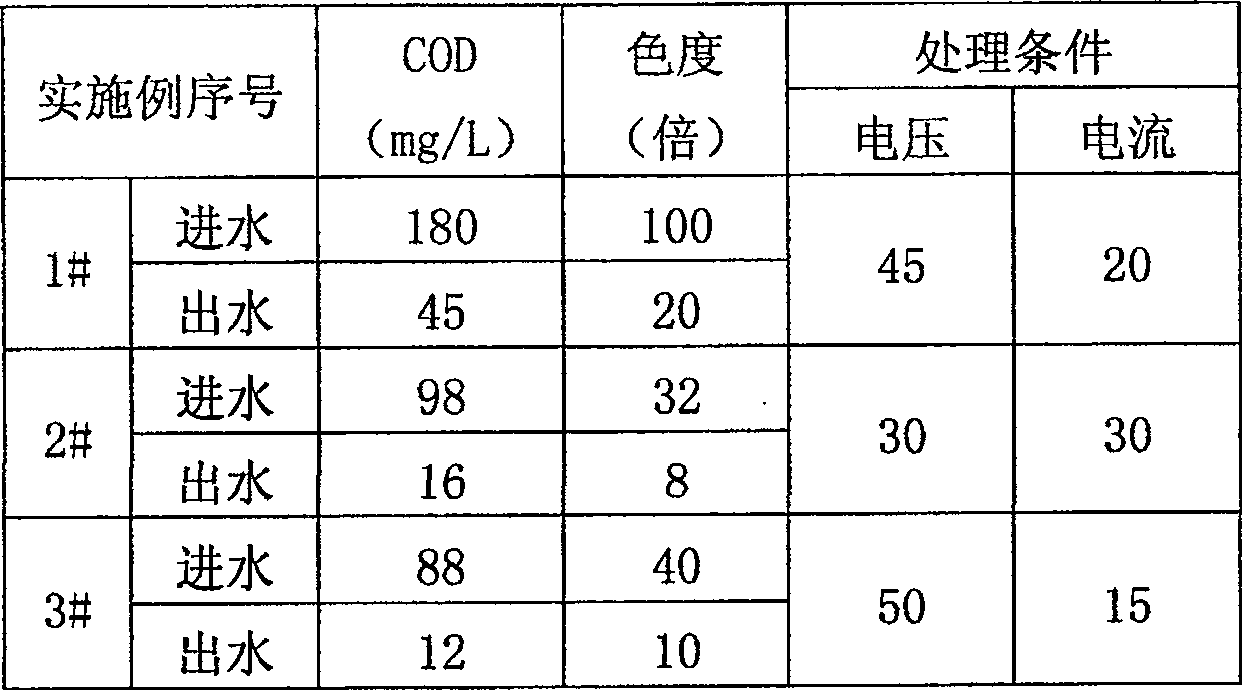

[0016] Depend on figure 1 It can be seen that the specific implementation method of the method of the present invention is: after the tail water treated by the conventional process is collected in the intermediate pool, it is pumped into the electrocatalytic reaction device. After the AC power is converted into DC power by the converter, it is connected to the electrocatalytic reactor, the control current is 15A to 50A, the voltage is 30V to 80V, the control residence time is 10 minutes to 1 hour, and the water consumption per ton is 0.5-3kw. After the wastewater is in contact with activated carbon and electrodes in the electrocatalytic reaction device, a catalytic oxidation reaction occurs, and the refractory organic matter and chroma in the wastewater are removed at the same time. After treatment, the effluent is discharged into the reuse pool. The up-to-standard tail water can be reused for production or up-to-standard discharge. The treated tail water is better than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com