Method for preparing high-purity magnesium aluminate spinel precursor

A pure magnesia-aluminum spinel and precursor technology, applied in the field of preparing high-purity magnesia-aluminum spinel precursors, can solve the problems of good particle dispersion, high efficiency, harsh raw material purity, etc., and achieve high purity and avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

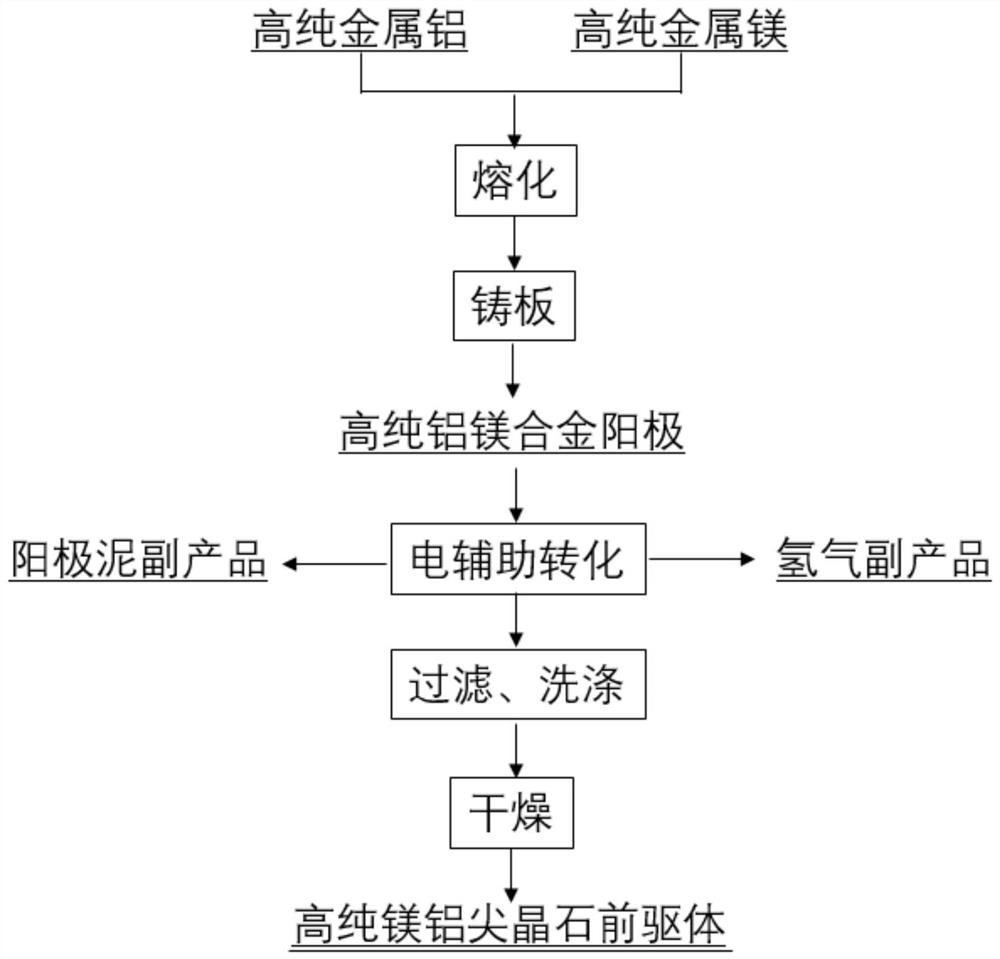

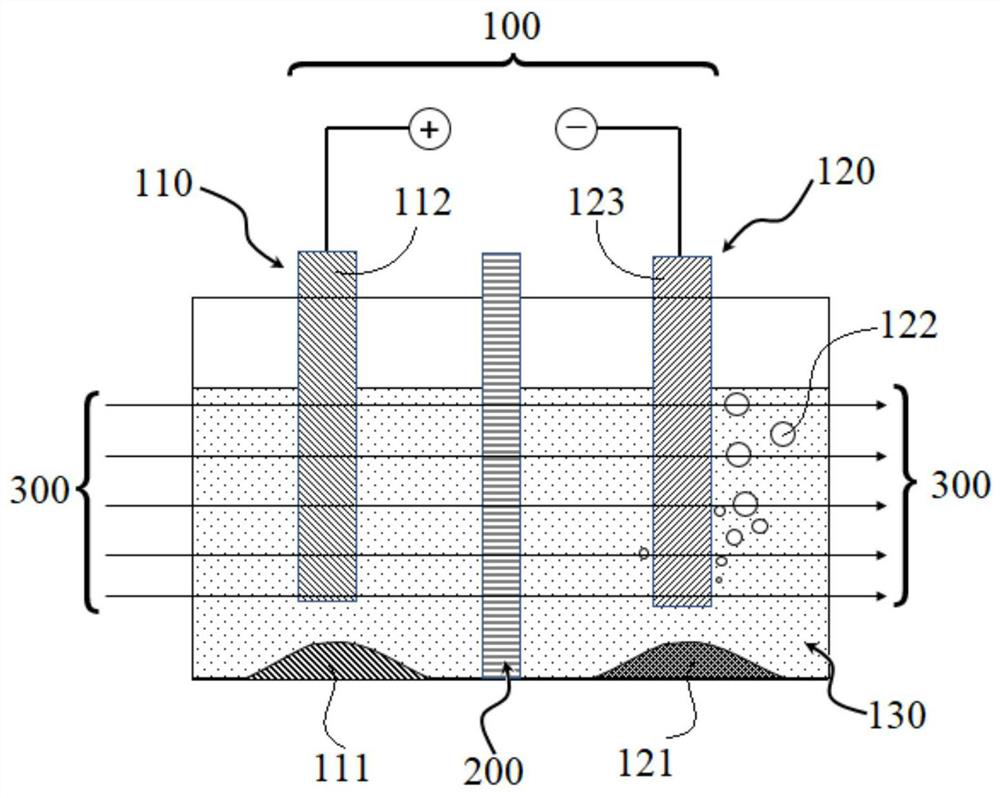

[0045] combine figure 1 As shown, a method for preparing a high-purity magnesium-aluminum spinel precursor in this embodiment, the steps are: select a high-purity aluminum-magnesium alloy as the anode plate 112, and obtain magnesium-aluminum hydroxide through electric-assisted conversion and an external field 300 Precipitate product 121, and then filter, wash and dry the magnesium-aluminum hydroxide precipitated product 121 successively to obtain a high-purity magnesium-aluminum spinel precursor. The specific steps are:

[0046] Step 1, preparation of anode plate 112

[0047] First heat high-purity aluminum and high-purity magnesium with a purity of 99-99.999% to melt, the molar ratio of magnesium to aluminum is in the range of 1:2-1:4, and then cast it into an aluminum-magnesium alloy plate, and the aluminum-magnesium alloy plate The surface is polished and cleaned to obtain the anode plate 112. After drying, it is stored in an inert gas environment for future use; the purp...

Embodiment 2

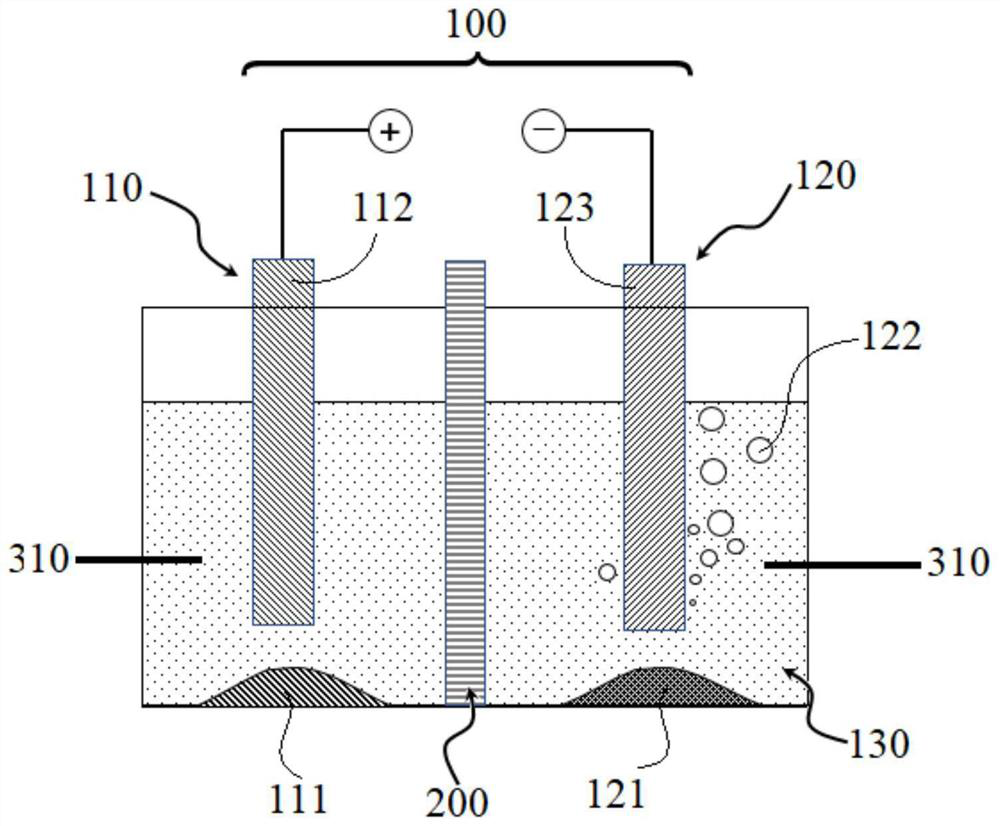

[0070] The present embodiment is basically the same as Embodiment 1, the difference being that the external field 300 is an ultrasonic field, and an anode ultrasonic transmitter 310 and a cathode ultrasonic transmitter 320 are respectively arranged at the anode electrolyzer 110 and the cathode electrolyzer 120, respectively to the anode electrolyzer 120. 110 and cathode electrolytic cell 120 emit an ultrasonic field; the ultrasonic frequency of the ultrasonic field is 20-3000 kHz, the ultrasonic power is 0-4000 W, and the ultrasonic external field application method in this embodiment is continuous application. The purity, maximum diameter and current efficiency of the electrolytic cell of the magnesium aluminum hydroxide product 121 obtained by electrolysis are recorded in Table 1. It can be seen that the maximum diameter of the obtained ultrapure alumina precursor is further reduced to 0.11 μm compared with Example 1, which may be due to the fact that the ultrasonic field dir...

Embodiment 3

[0072] This example is basically the same as Example 1, except that the electric field is applied intermittently, and the purity, maximum diameter and current efficiency of the electrolytic cell are recorded in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com