Lithium manganese phosphate clad lithium-rich layered oxide cathode material as well as preparation and application thereof

A cathode material and oxide technology, applied in the field of lithium-rich cathode materials and their preparation, achieves the effects of high specific capacity, good rate performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Lithium-rich cathode material Li[Li 0.17 Ni 0.25 mn 0.58 ]O 2 Preparation: Weigh LiOH·H 2 O (excess 8%) 2.644 grams, Ni (CH 3 COO) 2 2H 2 O 3.111 g, Mn(CH 3 COO) 2 2H 2 0.7.148 grams, be mixed with 200 milliliters of metal ion total concentration and be the aqueous solution of 0.52 mol / liter, add the citric acid of 200 milliliters of 1.0 mol / liter then, add ammoniacal liquor (massfraction 25%), the pH of mixed solution is adjusted to 9, Stir evenly; inject the above solution into a spray dryer for spray drying to obtain a uniformly mixed precursor; grind the obtained precursor into powder, transfer it to a crucible, and roast at 480°C for 5 hours. After cooling, grind the material ; Then place the ground material in a muffle furnace and sinter at a high temperature of 850°C for 10 hours to obtain Li[Li 0.17 Ni 0.25 mn 0.58 ]O 2 .

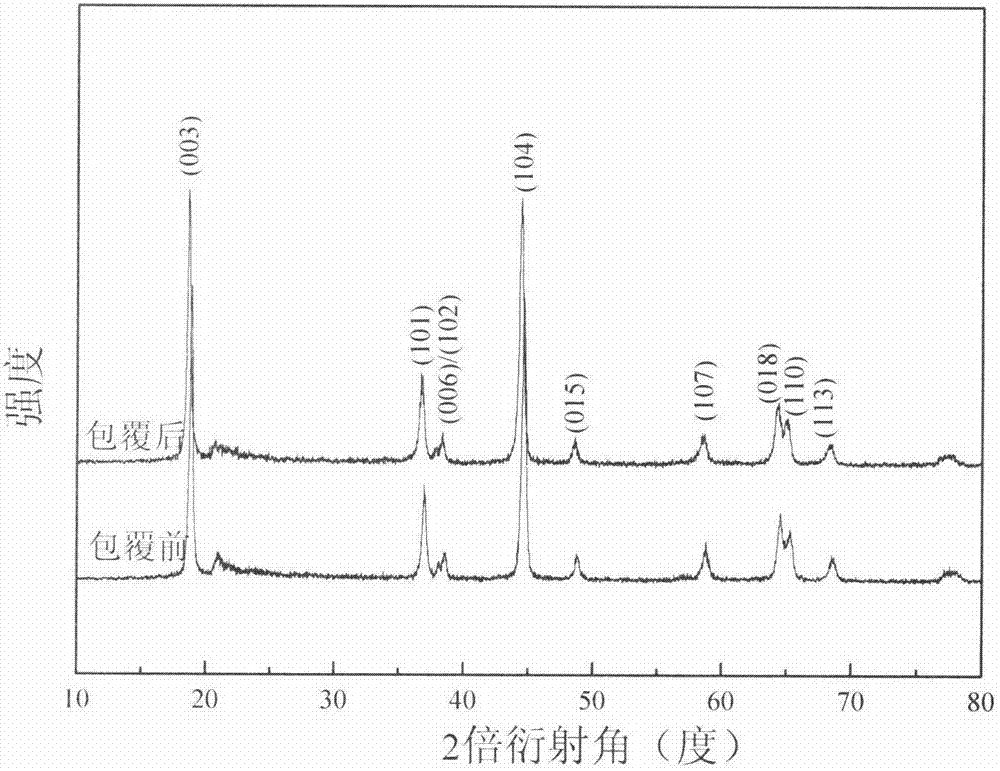

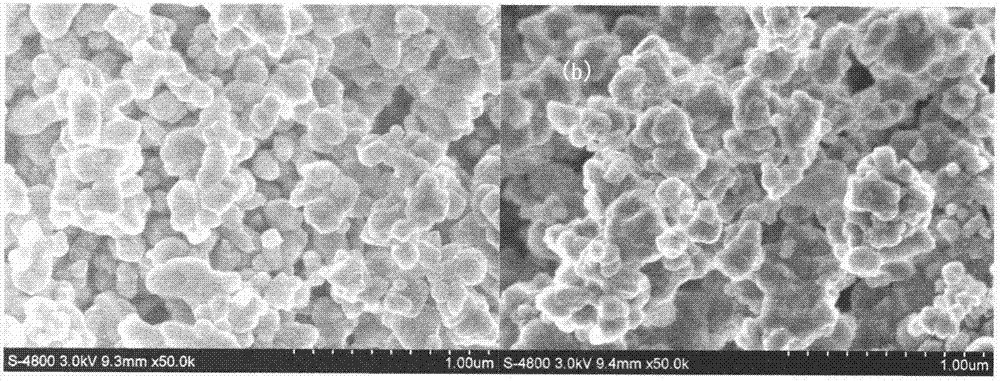

[0027] 2) LiMnPO 4 Coated Li[Li 0.17 Ni 0.25 mn 0.58 ]O 2 Preparation: Take the Li[Li prepared in step 1) 0.17 Ni 0....

Embodiment 2

[0030] Change the calcination temperature 400 DEG C in step 2) in embodiment 1 to 500 DEG C, and others are the same as embodiment 1. Electrochemical performance tests such as Figure 4 As shown, at a current density of 30 mA / g, the coated LiMnPO 4 The discharge capacity of the latter material after 80 weeks is 260.8 mAh / g, and the cycle performance has been significantly improved.

Embodiment 3

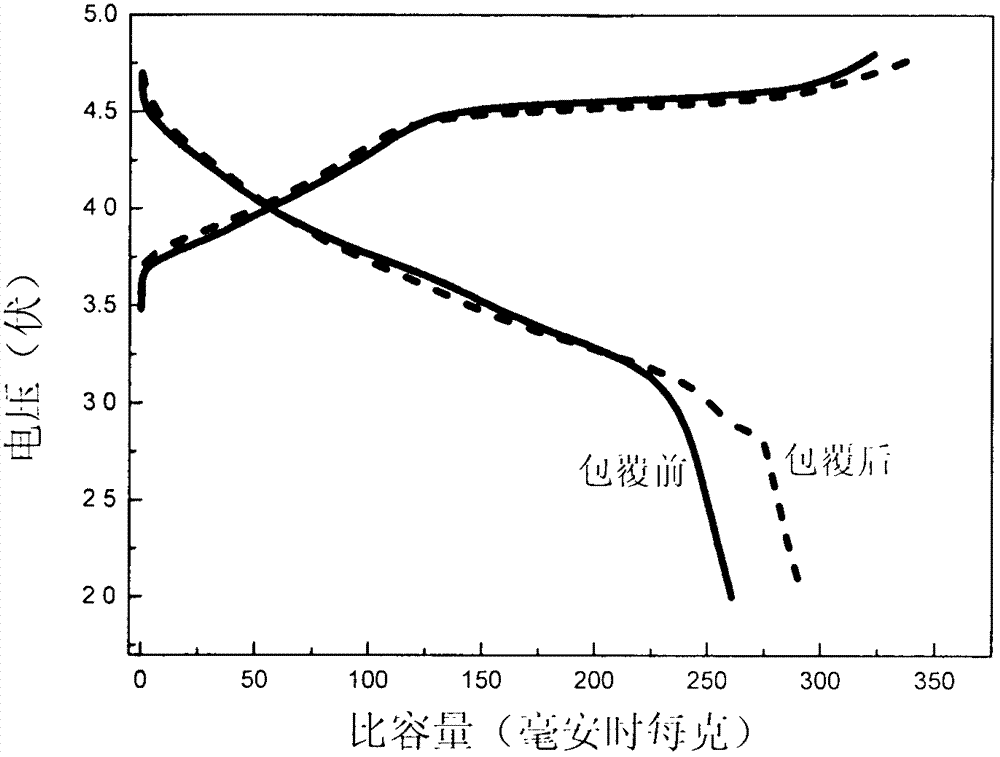

[0032] With the LiMnPO in step 2) in embodiment 1 4 with Li[Li 0.17 Ni 0.25 mn 0.58 ]O 2 Mass ratio control is 7wt%, other is the same as embodiment 1. Figure 5 Shown at a current density of 30 mA / g, the material in LiMnPO 4 The first cycle charge and discharge curves before and after coating, it can be seen from the figure that the initial discharge specific capacity of the material after coating has also been improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com