Anion-doped sodium ion battery oxide cathode material

A sodium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problems of poor cycle stability, limited commercial application, low capacity, etc. order, improve the effect of phase transition reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]Example 1: Weigh 13.9391g of sodium carbonate, 6.6877g of manganese dioxide, 5.7177g of nickelous oxide, and 8.0652g of ferric oxide into a ball mill jar. The ball mill jar was mechanically milled for 4 hours on a planetary ball mill with a rotational speed of 513r / min. Then, the precursor was calcined in a muffle furnace at 1000 °C for 12 h with a heating rate of 2 °C min -1 . After cooling to room temperature, the target product NaFe 0.4 Ni 0.3 mn 0.3 o 2 .

[0027] The active material was uniformly mixed with a conductive agent (acetylene black) and a binder (4% PVDF in NMP solution), and the ratio of the active material, conductive agent and binder was 70:20:10. The slurry was uniformly coated on the aluminum foil current collector, and dried in a vacuum oven at 100°C for 12 hours. After drying, the aluminum foil loaded with materials is punched into small discs using a punching machine.

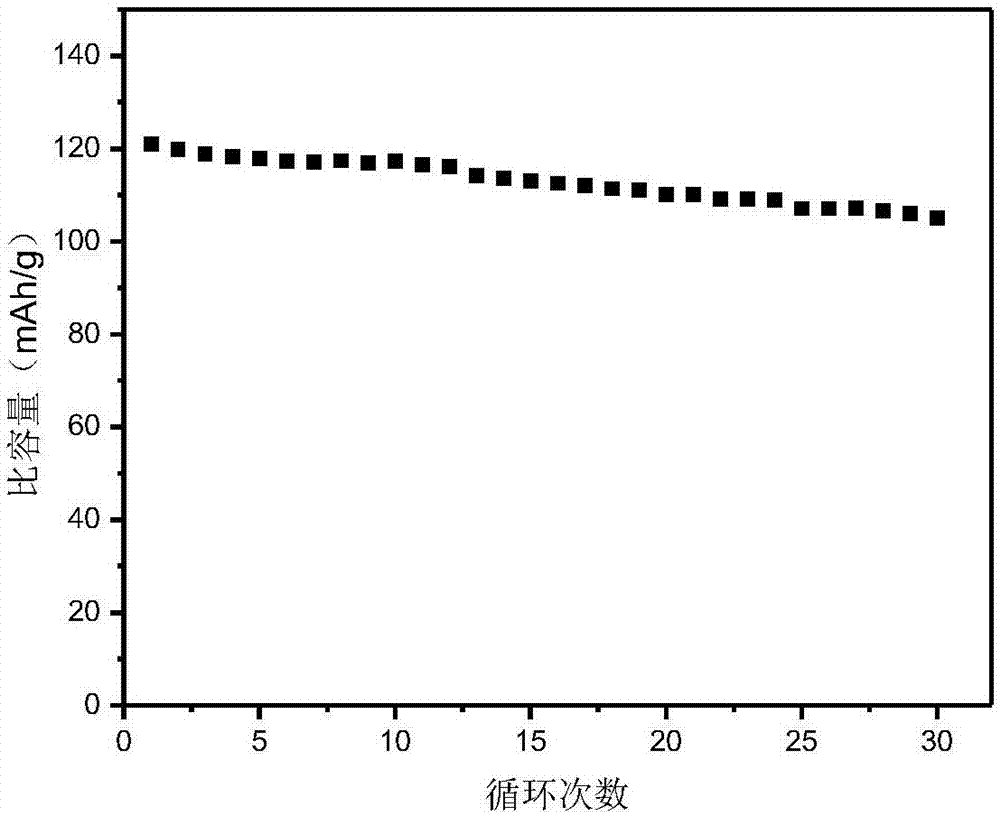

[0028] The electrode material pole piece is used as the working electr...

Embodiment 2

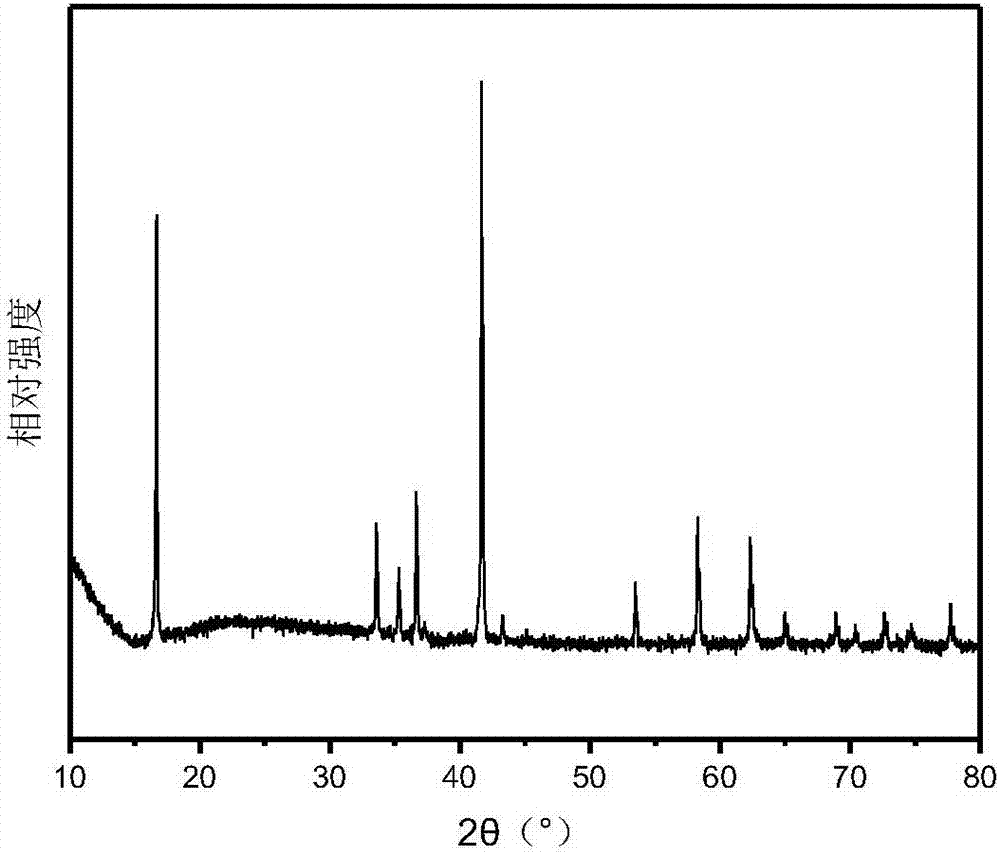

[0029] Example 2: 13.9391g of sodium carbonate, 6.6877g of manganese dioxide, 5.7177g of nickel oxide, 8.0652g of ferric oxide and 0.7768g of boric acid were weighed and added to a ball mill jar. The ball mill jar was mechanically milled for 4 hours on a planetary ball mill with a rotational speed of 513r / min. Then, the precursor was calcined in a muffle furnace at 1000 °C for 12 h with a heating rate of 2 °C min -1 . After cooling to room temperature, the target product NaFe 0.4 Ni 0.3 mn 0.3 o 1.925 (BO 3 ) 0.05 . The XRD pattern of the obtained product is as follows figure 2 shown.

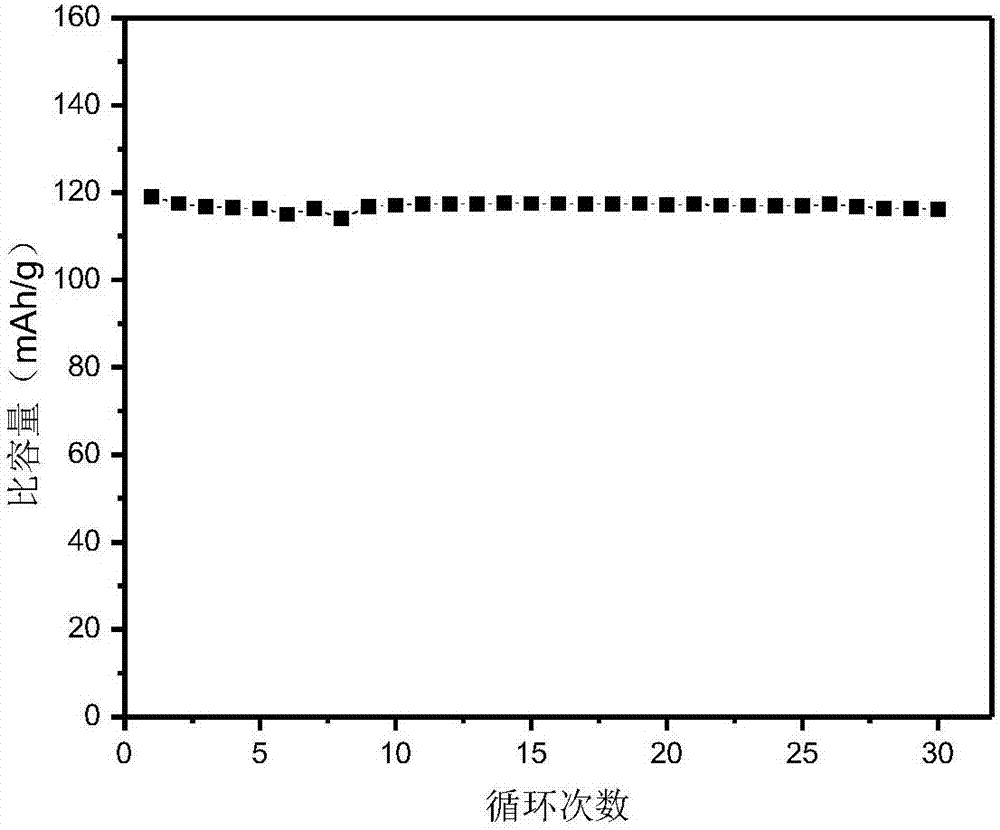

[0030] The electrochemical testing method of the material is the same as in Example 1. The cycle curve of the material in the first 30 weeks is as follows image 3 shown. The capacity retention rate of the material in the first 30 weeks was 97.6%, showing good cycle stability.

Embodiment 3

[0031] Example 3: 13.9391g of sodium carbonate, 6.6877g of manganese dioxide, 5.7177g of nickel oxide, 8.0652g of ferric oxide and 0.3107g of boric acid were weighed and added to a ball mill jar. The ball mill jar was mechanically milled for 4 hours on a planetary ball mill with a rotational speed of 513r / min. Then, the precursor was calcined in a muffle furnace at 1000 °C for 12 h with a heating rate of 2 °C min -1 . After cooling to room temperature, the target product NaFe 0.4 Ni 0.3 mn 0.3 o 1.97 (BO 3 ) 0.02 .

[0032] The electrochemical testing method of the material is the same as in Example 1. The charge-discharge curve of the material in the first week is as follows: Figure 4 As shown, it has an initial discharge specific capacity of 131.6mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com