Preparation method of high compaction density lithium ion cathode material

A cathode material, lithium ion technology, applied in the field of battery cathode material preparation, can solve the problems of easy particle agglomeration, complicated mixing process, difficult operation control, etc., to achieve optimization of sintering process, good processing performance, and improved compaction density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

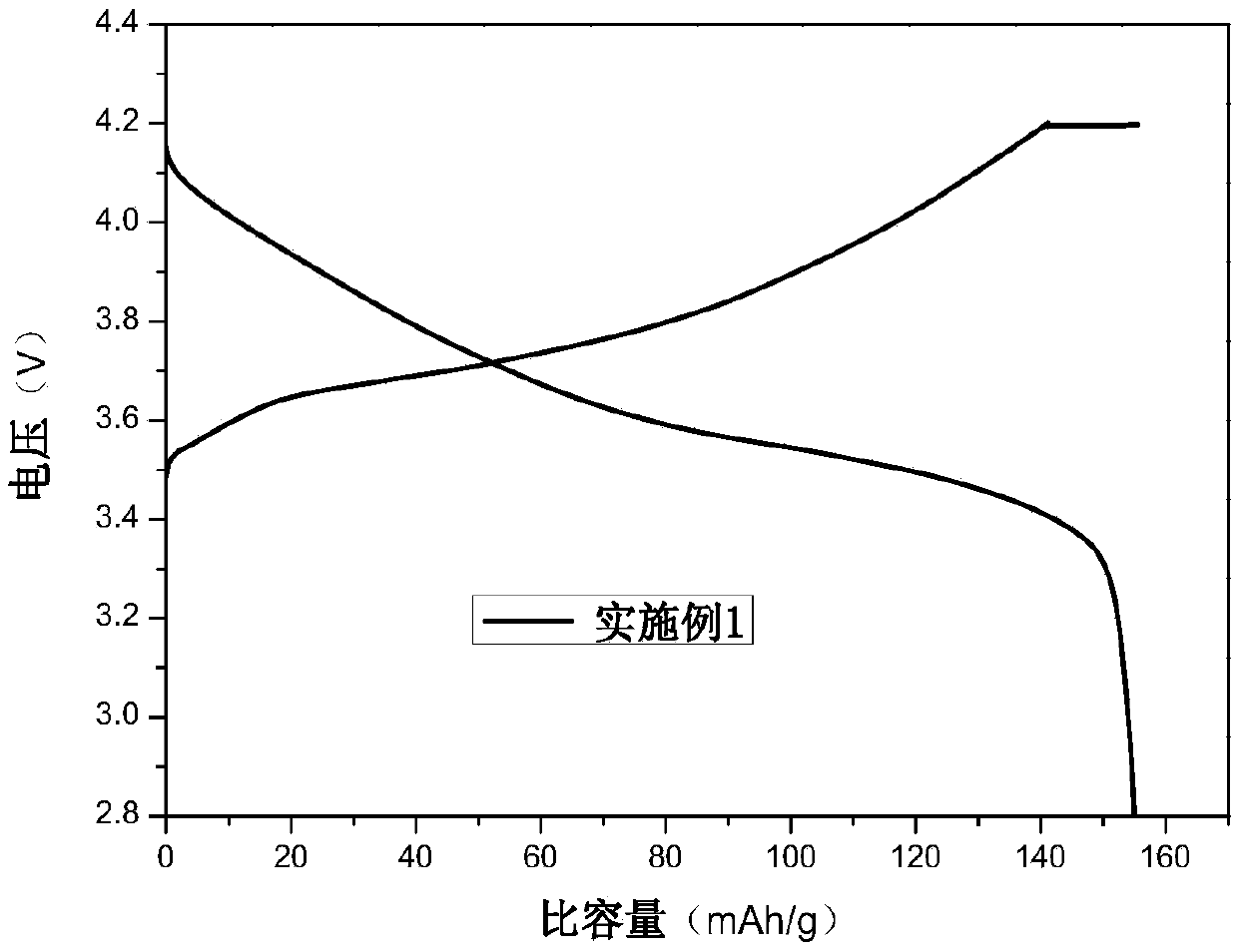

Embodiment 1

[0033] A preparation method of a high compacted density lithium-ion battery cathode material of the present invention, comprising the following steps:

[0034] (1) Pretreatment of precursor: mix boric acid with absolute ethanol to form a transparent and clear boric acid-ethanol solution, and add precursor powder Ni 0.5 co 0.2 mn 0.3 (OH) 2 , to form a suspension, and continue to stir for 1 hour, then put in a water bath at 70° C., and continue to stir until the absolute ethanol evaporates to dryness, and then dry to obtain a pretreated precursor. In the suspension, boric acid accounts for 0.5 wt.% of the total mass of the precursor and boric acid, and the mass ratio of the precursor to ethanol is 1:0.5.

[0035] (2) Ingredients: the pre-treated precursor and lithium carbonate obtained in step (1) are placed in a mixer and mixed evenly, and the Li:(Ni 0.5 co 0.2 mn 0.3 ) The mol ratio is 1.08, obtains mixture.

[0036] (3) Sintering: Divide the mixture obtained in step (2)...

Embodiment 2

[0045] A preparation method of a high compacted density lithium-ion battery cathode material of the present invention, comprising the following steps:

[0046] (1) Pretreatment of precursor: mix boric acid with absolute ethanol to form a transparent and clear boric acid-ethanol solution, and add precursor powder Ni 0.5 co 0.2 mn 0.25 Mg 0.05 CO 3 , form a suspension, and keep stirring for 1 hour, then place it in a water bath at 70°C, and keep stirring until the solvent is evaporated to dryness and dried to obtain a pretreated precursor. In the suspension, boric acid accounts for 0.5 wt.% of the total mass of the precursor and boric acid, and the mass ratio of the precursor to ethanol is 1:0.5.

[0047] (2) Ingredients: the pretreated precursor and lithium carbonate obtained in step (1) are placed in a mixer and mixed evenly, and the Li:(Ni 0.5 co 0.2 mn 0.25 Mg 0.05 ) The mol ratio is 1.08, obtains mixture.

[0048] (3) Sintering: The mixture obtained in step (2) is ...

Embodiment 3

[0051] A preparation method of a high compacted density lithium-ion battery cathode material of the present invention, comprising the following steps:

[0052] (1) Pretreatment of precursors: miscible boric acid and deionized water to form a transparent and clear boric acid-water solution, and add ternary precursor powder Ni during the stirring process 0.6 co 0.2 mn 0.2 (OH) 2 , form a suspension, and keep stirring for 1 hour, then place it on an electric furnace, continue stirring until the water is evaporated to dryness, and then dry it to obtain a pretreated ternary precursor material. In the suspension, the percentage of boric acid to the total mass of the ternary precursor material and boric acid is 0.5 wt.%, and the mass ratio of the precursor to water is 1:0.5.

[0053] (2) Ingredients: the pretreated ternary precursor and lithium carbonate obtained in step (1) are placed in a mixer and mixed evenly, and the Li:(Ni 0.6 co 0.2 mn 0.2 ) The mol ratio is 1.10, obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com