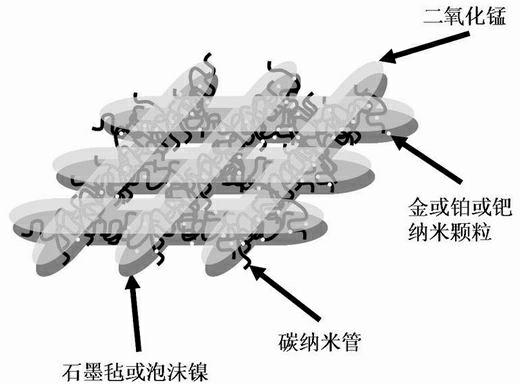

Combined electrode for super capacitor and preparation method thereof

A technology of supercapacitors and composite electrodes, which is applied in the manufacture of hybrid capacitor electrodes, capacitors, and hybrid/electric double-layer capacitors, etc. Improved, high theoretical specific capacitance, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of graphite felt / carbon nanotube / palladium / manganese dioxide composite electrode:

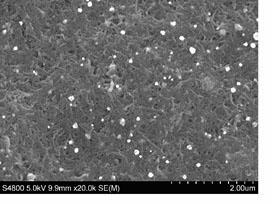

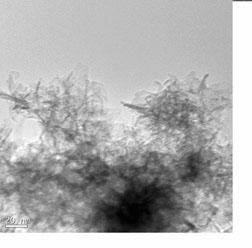

[0027] Using constant potential electrophoretic deposition technology, the graphite felt substrate was used as the working electrode, the platinum electrode was used as the counter electrode, and the aqueous solution of 1.1 g / L carbon nanotubes was used as the electrolyte, and the carbon nanotube layer was electrophoretically deposited on the surface of the graphite felt substrate with a deposition potential of 10 V. After drying, a graphite felt / carbon nanotube electrode is obtained. Using constant potential electrodeposition technology, using graphite felt / carbon nanotube electrode as working electrode, platinum electrode as counter electrode, saturated calomel electrode as reference electrode, 8.5mM PdCl 2 and 0.49M H 3 BO 3 The mixed aqueous solution was used as the electrolyte, and the palladium nanoparticles were electrochemically deposited on the graphite felt / carbo...

Embodiment 2

[0030] Preparation of graphite felt / carbon nanotube / palladium / manganese dioxide composite electrode:

[0031] Using the constant potential electrophoretic deposition technology, the graphite felt substrate was used as the working electrode, the platinum electrode was used as the counter electrode, and the aqueous solution of 0.8 g / L carbon nanotubes was used as the electrolyte, and the carbon nanotube layer was electrophoretically deposited on the surface of the graphite felt substrate with a deposition potential of 10 V. After drying, a graphite felt / carbon nanotube electrode is obtained. Using constant potential electrodeposition technology, using graphite felt / carbon nanotube electrode as working electrode, platinum electrode as counter electrode, saturated calomel electrode as reference electrode, 8.5mM PdCl 2 and 0.49M H 3 BO 3 The mixed aqueous solution was used as the electrolyte, and the palladium nanoparticles were electrochemically deposited on the graphite felt / c...

Embodiment 3

[0035] Preparation of graphite felt / carbon nanotube / platinum / manganese dioxide composite electrode:

[0036] Using the constant potential electrophoretic deposition technology, the graphite felt substrate was used as the working electrode, the platinum electrode was used as the counter electrode, and the aqueous solution of 1.2 g / L carbon nanotubes was used as the electrolyte, and the carbon nanotube layer was electrophoretically deposited on the surface of the graphite felt substrate with a deposition potential of 10 V. After drying, a graphite felt / carbon nanotube electrode is obtained. Using constant potential electrodeposition technology, graphite felt / carbon nanotube electrode was used as working electrode, platinum electrode was used as counter electrode, saturated calomel electrode was used as reference electrode, and 5 mmol / L H 2 PtCl 6 and a mixed aqueous solution of 1.2 mmol / L HCl as the electrolyte, electrochemically deposited platinum nanoparticles on the graphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com