Apparatus and method for catalytic oxidation of magnesium sulfite, and cobalt nitrate/ZSM-5 molecular sieve catalyst and preparation method thereof

A technology of magnesium sulfite oxide and ZSM-5, which is applied in the direction of molecular sieve catalysts, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of large evaporation energy consumption, large oxidation area, Problems such as heavy metal ion pollution, operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides the preparation method of above-mentioned cobalt nitrate / ZSM-5 molecular sieve catalyst, comprises the following steps:

[0050] (1) ZSM-5 molecular sieve and cobalt nitrate solution are mixed for ion exchange to obtain a catalyst precursor;

[0051] (2) Calcining the catalyst precursor to obtain a cobalt nitrate / ZSM-5 molecular sieve catalyst.

[0052] In the invention, ZSM-5 molecular sieve is mixed with cobalt nitrate solution for ion exchange to obtain catalyst precursor. In the present invention, there is no special requirement on the source of the ZSM-5 molecular sieve, and conventional commercially available ZSM-5 molecular sieves in the field can be used. In the present invention, the molar concentration of the cobalt nitrate solution is preferably 0.1 to 0.3 mol / L, more preferably 0.15 to 0.2 mol / L; the volume ratio of the ZSM-5 molecular sieve to the cobalt nitrate solution is preferably 2 ~10 g: 100 mL, more preferably 4 ~ 8 g: 100 mL...

Embodiment 1

[0062] Preparation of cobalt nitrate / ZSM-5 molecular sieve catalyst:

[0063] (1) Add 4g of ZSM-5 molecular sieve to 100mL of 0.15mol / L cobalt nitrate solution, perform ion exchange under 80°C water bath condition, the exchange time is 24h, and repeat the ion exchange after replacing the cobalt nitrate solution;

[0064] (2) The above solution is centrifuged at a speed of 4500r / min, the supernatant is discarded, and washed three times with deionized water;

[0065] (3) The solid after centrifugal cleaning was dried in a drying oven at 80°C for 6h, calcined in a muffle furnace at 300°C for 2h, and the heating rate was 2°C / min to obtain a cobalt nitrate / ZSM-5 molecular sieve catalyst, the mass of cobalt nitrate in the catalyst 5% load;

[0066] Use gained catalyst to catalyze magnesium sulfite oxidation, concrete method is as follows:

[0067] Take 200mL of deionized water in the reactor, add magnesium sulfite and catalyst into the reactor, feed air, and start timing at the sa...

Embodiment 2

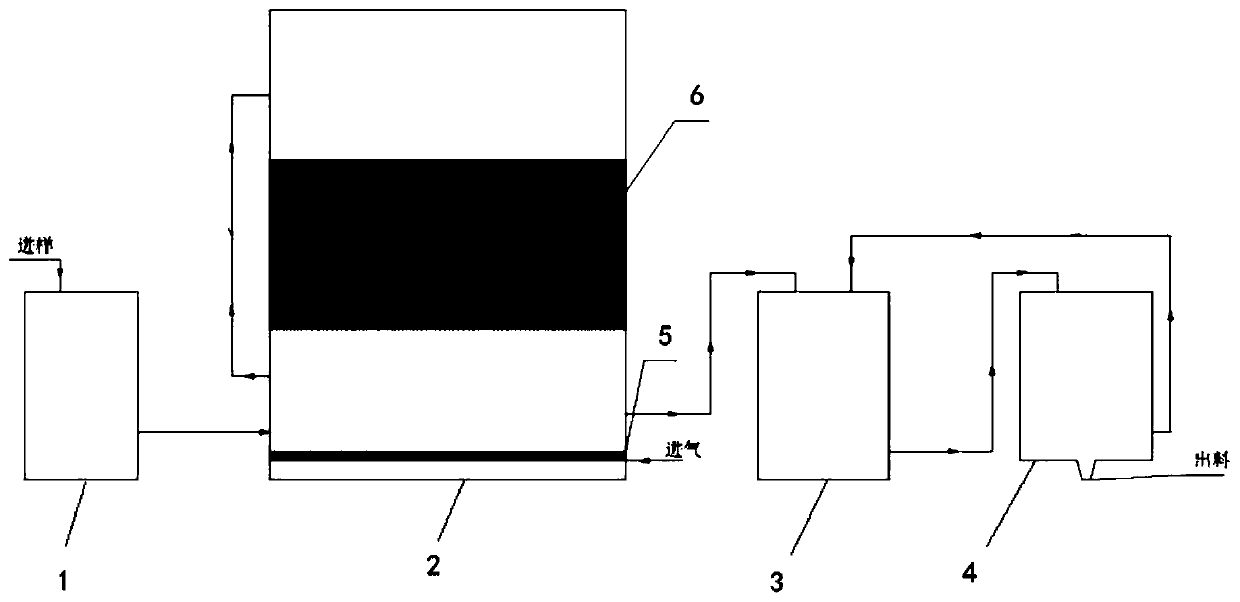

[0072] Use the device of catalytic oxidation magnesium sulfite provided by the present invention to carry out catalytic oxidation to the magnesium sulfite solid of magnesium method desulfurization power plant, concrete method is as follows:

[0073] (1) the magnesium sulfite raw material enters the preparation box and mixes with water, and obtains the magnesium sulfite slurry through stirring, wherein the mass concentration of the magnesium sulfite slurry is 45%;

[0074] (2) The magnesium sulfite slurry enters the reaction box to contact with the catalyst, at 200m 3 Carry out oxidation reaction under / h aeration condition, obtain magnesium sulfate slurry, wherein the temperature of oxidation reaction is 45 ℃, and catalyzer is the cobalt nitrate / ZSM-5 molecular sieve catalyst that embodiment 1 gains, its quality and the volume of magnesium sulfate slurry The ratio is 40g: 1L;

[0075] (3) the magnesium sulfate slurry enters the evaporator and is concentrated to 60% of the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com