Thermal power plant wet desulphurization wastewater advanced treatment combined process

A wet desulfurization and advanced treatment technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of few pilot test or engineering application cases, complex management and maintenance process, and easy occurrence Operation management and other issues to achieve the effect of salt recovery, high-quality water production, and improved chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

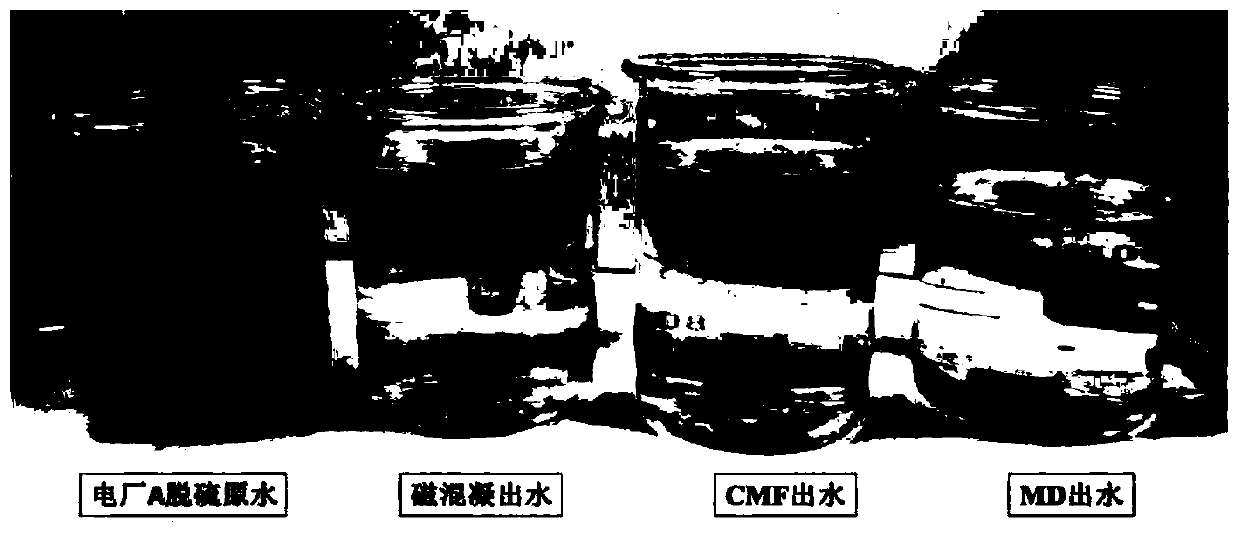

Embodiment 1

[0028] "Microfiltration + membrane distillation" is used for advanced treatment of power plant desulfurization wastewater. The wastewater is taken from a power plant. The pH, chroma, turbidity, COD, and conductivity of the wastewater are 6.57, 480 times, 73NTU, 1647mg / L, and 58.03mS / cm respectively. . The PVDF microfiltration membrane is used for suspended solids treatment, the average pore size of the membrane is 0.13μm, and the turbidity of the effluent is lower than 2.5NTU. Further adopt membrane distillation treatment, adopt PVDF hydrophobic membrane, the cold side temperature is 20, the heat measurement temperature is 40-80°C, and the produced water flux is 10.63-37.00kg / m 2 h, the conductance of the product water was lower than 10μS / cm under all temperature conditions, and the salt rejection rate was higher than 99.99%. The removal rate of suspended matter, potassium, calcium, sodium, magnesium, sulfate, Cl and COD in the overall process is higher than 97%.

Embodiment 2

[0030] PAM is used to treat the suspended solids of desulfurization wastewater. The desulfurization wastewater is taken from a power plant with a pH of 4.78, SS of 78.47g / L, COD of 820mg / L, and conductance of 68.6μS / cm. Under the condition that the dosage of PAM is 0.2g / L, the turbidity of the effluent is 27.5NTU. Further use PVDF microfiltration membrane for suspended matter treatment, the membrane pore size is 0.13μm, and the turbidity of the effluent is lower than 2NTU. Afterwards, membrane distillation was used for advanced treatment. The hydrophobic membrane used was PVDF-CTFE membrane. Under the conditions of temperature difference of 40°C and cold side flow rate of 0.3 L / min, the hot side flow rate was 0.2, 0.3, 0.4 L / min. The water flux is 24.43, 25.24, 26.42kg / m 2 h. After continuous operation for 6 hours, the conductivity of the product water is lower than 10μS / cm, and the salt rejection rate is higher than 99.99%. Membrane distillation process exhibits high produ...

Embodiment 3

[0032] A combined process is used to treat desulfurization wastewater. The wastewater is taken from a power plant. The pH, conductivity, turbidity, SCOD, SS, and TDS are 6.7, 22.9mS / cm, 2506NTU, 347mg / L, 3.28g / L, 31.39g / L and 28.225g / L. Magnetic loading lime coagulation is used for treatment, the magnetic seed particle size is 400 mesh, the dosage of PAC, PAM, magnetic seed, and lime is 600, 3.75, 600, 800mg / L respectively, and the speed and time of fast stirring are 350rpm and 20s. The turbidity of the product water is 3.27NTU, the removal rate of suspended solids is 99.87%, the hardness and organic matter have been removed to a certain extent, and the amount of sludge is 2 / 3 of that of conventional coagulation. Afterwards, membrane distillation was used for advanced treatment. The hydrophobic membrane used was PVDF-CTFE membrane. When the temperature difference was 30°C, it was operated continuously for 100 hours, and the membrane flux dropped from 16.03 to 13.82kg / m 2 h, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com