Metal composite in-situ nitrogen-doped carbon microsphere catalyst and application thereof

A technology of nitrogen-doped carbon and metal compounding, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of slow catalytic rate, poor treatment effect, and large dosage, and achieve process Simple, fast and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Embodiment 1: This embodiment is a method for preparing a metal composite in-situ nitrogen-doped carbon microsphere catalyst, which is completed according to the following steps:

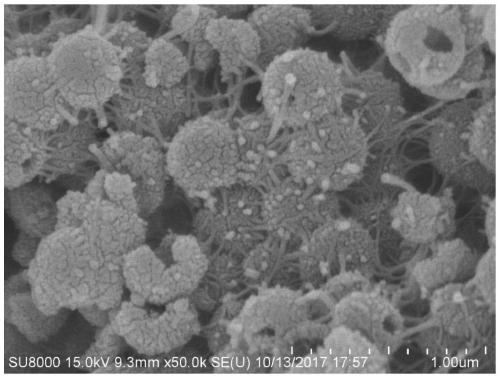

[0025] 1. Preparation of in-situ nitrogen-doped carbon microspheres: Add nitrogen-containing organic polymer monomers and templates to alcohol solution to obtain a mixed reaction solution; stir the mixed reaction solution at a stirring speed of 30r / min to 100r / min Stir and react for 30h to 45h to obtain nitrogen-containing organic polymer microspheres with a particle size of 100nm to 800nm; place nitrogen-containing organic polymer microspheres in a protective atmosphere heating device, and perform high-temperature carbonization under a protective gas atmosphere to obtain the original Nitrogen-doped carbon microspheres;

[0026] The concentration of the nitrogen-containing organic polymer monomer in the mixed reaction solution described in step 1 is 1 g / L to 20 g / L;

[0027] The templating a...

specific Embodiment approach 2

[0040] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the nitrogen-containing organic polymer monomer described in step one is 2-chloroacetamide, pyrrole, aniline, ethylenediamine, dopamine, o-phenanthro Any one of morphine, hexamethylenetetramine, dicyandiamide, urea, 2-amino-2-methyl-1,3-propanediol and carbedopa. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the protective atmosphere heating equipment described in step 1 is a high-temperature box-type atmosphere furnace, a high-temperature tube-type atmosphere furnace, and a protective atmosphere medium-frequency induction diathermy Any one of the furnace and the continuous protective atmosphere mesh belt furnace. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com