Method for preparing nitrogen-doped titanic acid nano tube by hydrothermal cosolvent method

A technology of titanate nanotubes and nitrogen doping, which is applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of poor stability of titanate nanotubes and poor effect of organic pollutants, and achieve uniform and stable appearance. Good performance and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

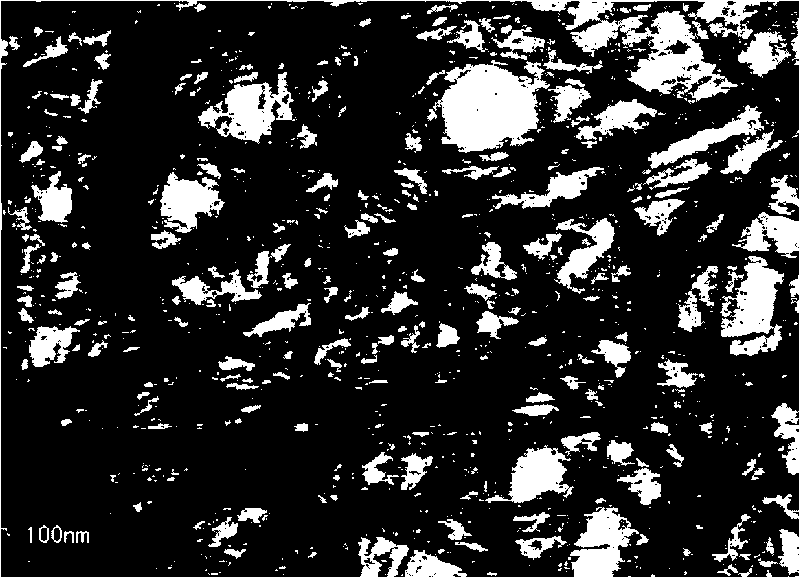

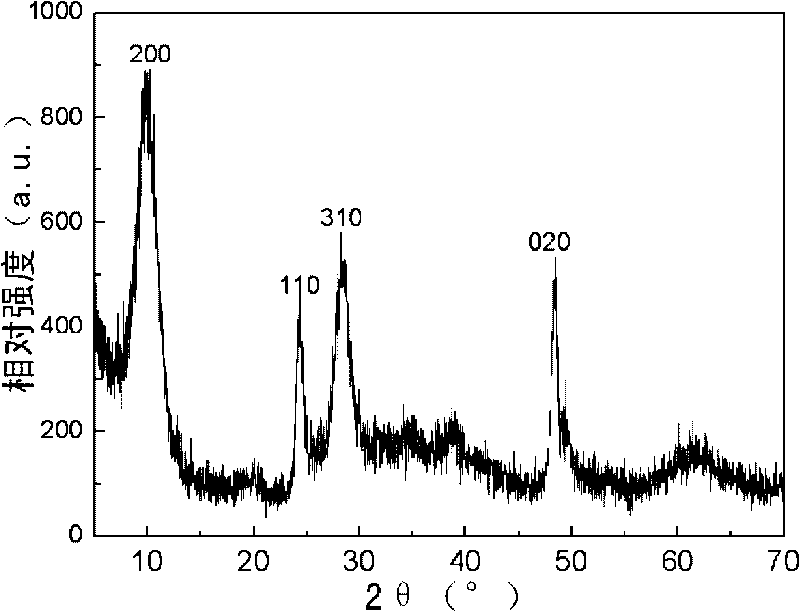

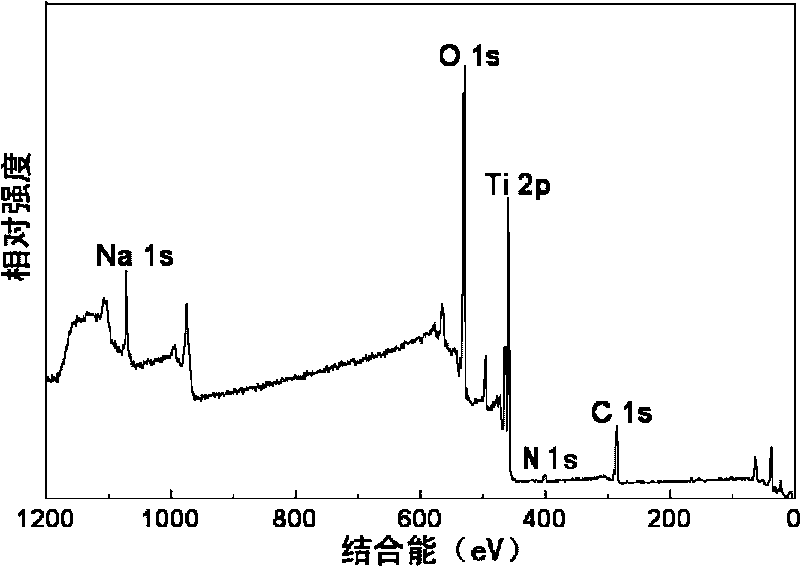

[0014] Specific embodiment 1: The preparation method of nitrogen-doped titanic acid nanotubes in this embodiment is realized through the following steps: 1. Mix the sodium hydroxide solution and triethanolamine in a ratio of 1:1 to 5 by volume Obtain the blended liquid, then ultrasonically disperse the blended liquid, add anatase-type nano-titanium dioxide into the blended liquid, then move the blended liquid into a hydrothermal reactor, seal the hydrothermal reactor, and then react at 150-200°C After 12 to 20 hours, cool to room temperature by self-heating, and then filter off the supernatant in the hydrothermal reactor to obtain the reaction product, wherein the molar concentration of the sodium hydroxide solution is 8 to 15 mol / L, and the ratio of the mass of titanium dioxide to the volume of the blended solution is 1g: 20-50mL; 2. Wash the reaction product obtained in step 1 to neutrality with hydrochloric acid and then to neutrality with deionized water, and then vacuum-dr...

specific Embodiment approach 2

[0018] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, sodium hydroxide and triethanolamine are mixed at a volume ratio of 1:3 to obtain a blend. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the blend solution is ultrasonically dispersed in an ultrasonic wave with a power of 180-300W for 20-40 minutes. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com