Method and device for ultra-gravity catalytic wet oxidation of phenolic wastewater

A technology for catalyzing wet oxidation and phenolic wastewater, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc. , The effect of reducing equipment volume, reducing mass transfer resistance and lowering catalytic rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

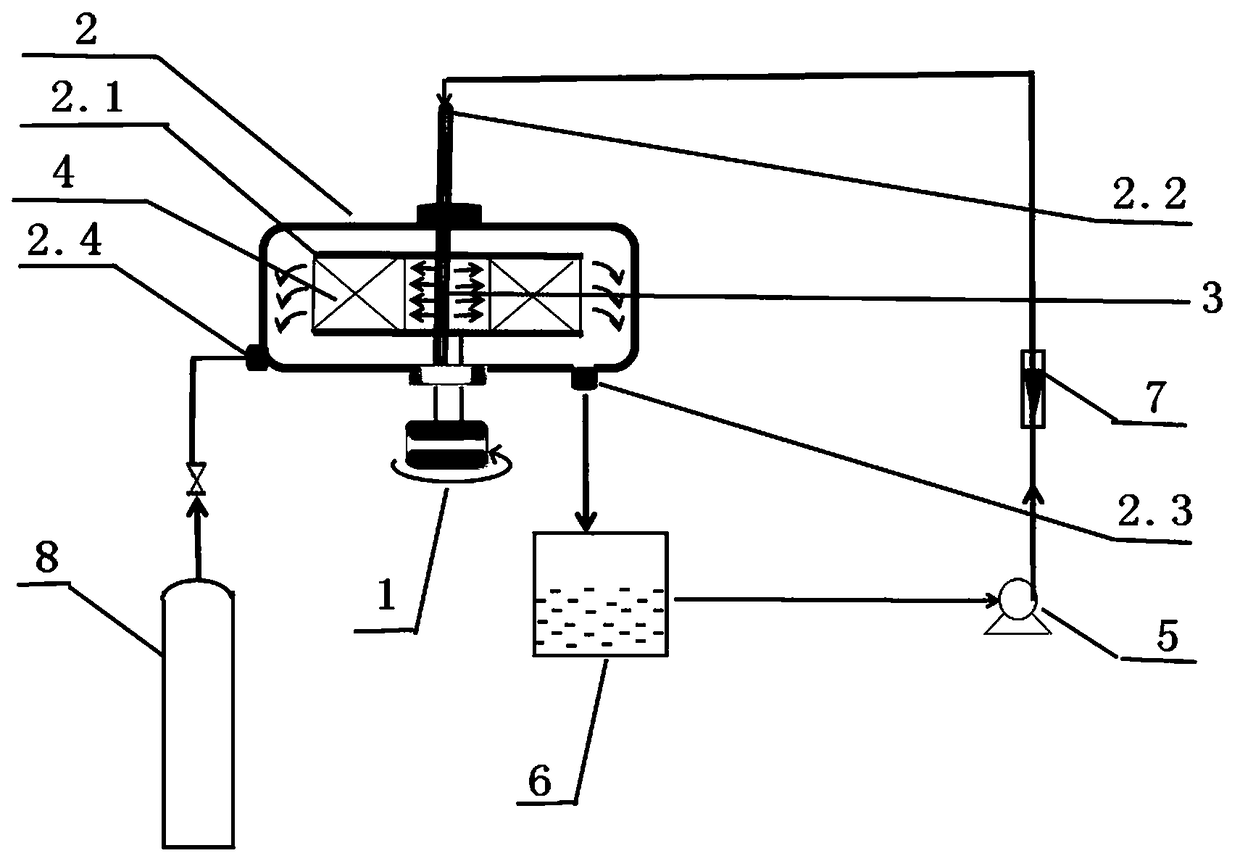

[0015] Example 1: A method for catalyzing wet oxidation of phenol-containing wastewater by a high-gravity rotating packed bed. The phenol-containing wastewater is sent into the high-gravity rotating packed bed through a liquid inlet pipe, and is initially distributed under the action of a liquid distributor. Driven into the high-gravity rotating packed bed to complete the micronization of droplets, and then enter the surface of the adsorbent loaded with catalyst, and at the same time complete the degradation of phenol-containing wastewater with the oxidant under the double action of catalyst and high gravity, and finally discharge through the liquid outlet pipe into the reservoir.

[0016] The concentration is 500 mg / L phenolic wastewater, and the spray density is 0.5 m 3 / m 2 / h, enter the rotating packed bed from the liquid inlet 2.2, and carry out the initial distribution under the action of the liquid distributor 3, and then, driven by the rotor 2.1 (supergravity factor 2...

Embodiment 2

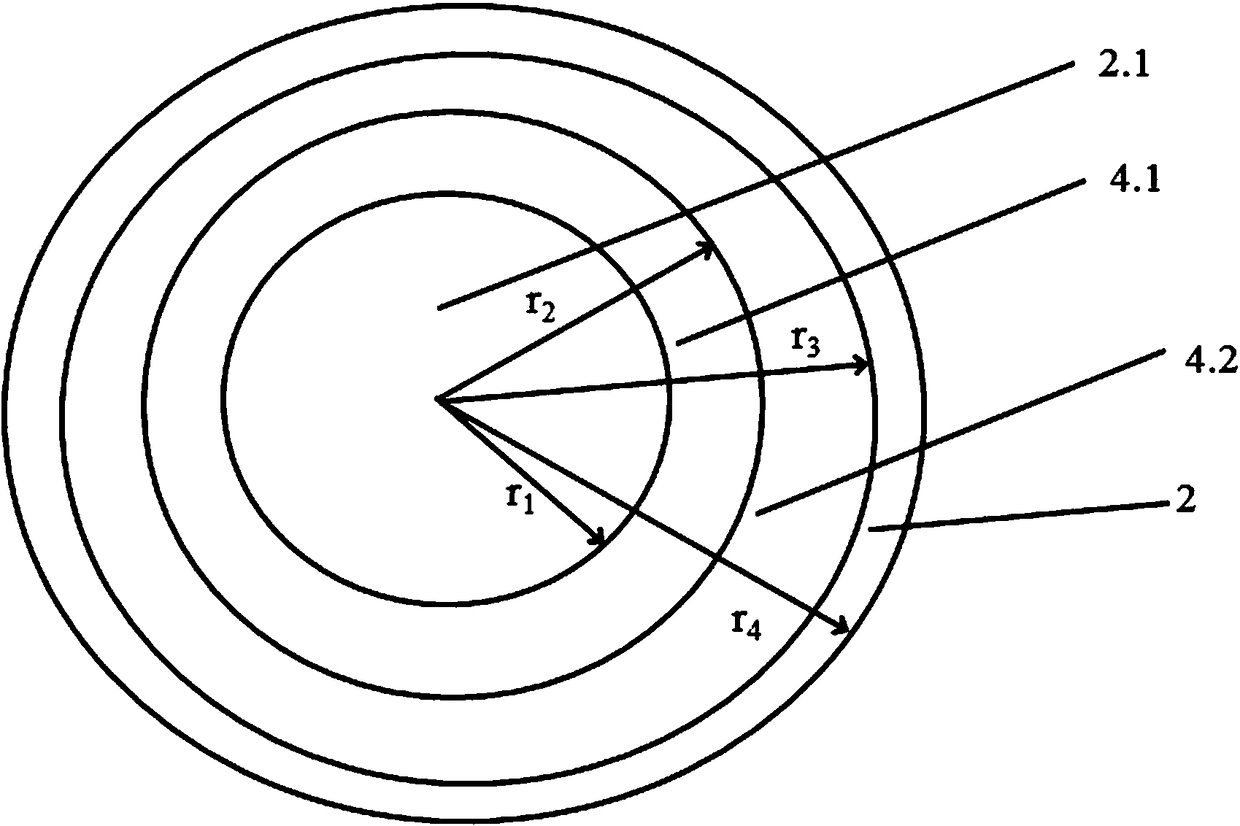

[0017] Embodiment 2: the concentration is 100 mg / L phenol-containing wastewater, and the spray density is 1 m 3 / m 2 / h, enter the rotating packed bed from the liquid inlet 2.2, carry out the initial distribution under the action of the liquid distributor 3, and then enter the packing area (Pall ring packing) driven by the rotor 2.1 (super gravity factor 5) to phenol-containing The waste water liquid is cut into tiny droplets, liquid filaments and liquid films, and then enters the surface of alumina loaded with iron. The amount of alumina is 30g, and the catalyst loading is 5.6 wt%. The catalyst loading area is a ring, and the size is supergravity rotation One-eighth of the cross-sectional area of the packed bed is mixed with the oxygen generated by the gas generator 8 (oxygen partial pressure 1.2MPa), and under its action, the degradation of phenol-containing wastewater is completed, and then the liquid is discharged into the liquid storage tank 6, Loop twice. Under the s...

Embodiment 3

[0018] Embodiment 3: Concentration is 800 mg / L containing phenol wastewater (containing 5% H 2 o 2 , 5 mM / L), the spray density is 2 m 3 / m 2 / h, enter the rotating packed bed from the liquid inlet 2.2, carry out initial distribution under the action of the liquid distributor 3, and then enter the packing area (Raschig ring packing) driven by the rotor 2.1 (high gravity factor 80) to phenol-containing The wastewater liquid is cut into tiny droplets, liquid filaments and liquid films, and then enters the surface of the copper-loaded zeolite. The amount of zeolite is 45g, the catalyst loading is 8.2 wt%, and the catalyst loading area is a ring, the size of which is a high-gravity rotating packed bed One-twentieth of the inner cross-sectional area, and then complete the degradation of phenol-containing wastewater under its action, and then the liquid is discharged into the liquid storage tank 6 for three cycles. Under the strengthening effect of supergravity, phenol molecules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com