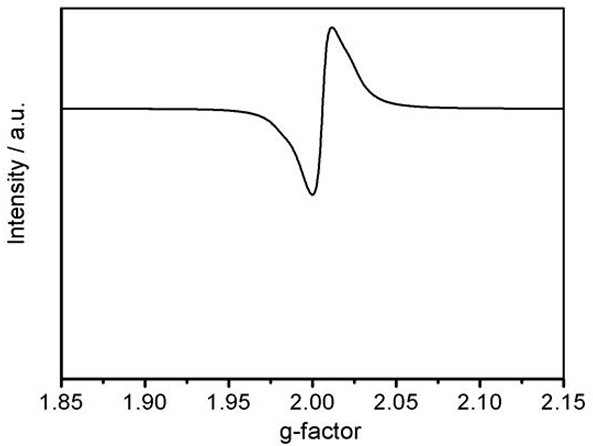

Nitroxide free radical functionalized porous organic polymer nanotubes as well as preparation method and application thereof

A nitroxide free radical and functionalization technology, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, catalytic reactions, etc., can solve the problems of limiting the diffusion rate of substrates and products, and achieve large The effect of contact area, fast catalytic efficiency and simple reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]A kind of preparation method of nitroxide radical functionalized porous organic polymer nanotube catalyst of the present invention, it comprises the following steps:

[0039] (a) Add the palladium catalyst and cuprous iodide into the reaction flask under nitrogen gas, then add the aromatic alkyne monomer and nitrogen oxide radical functionalized monomer into the reaction flask, perform gas extraction for 4 times, and Vacuum 2 h;

[0040] (b) Add the organic solvent into the reaction system of step (a) under nitrogen, freeze the pumped gas for 4 times with liquid nitrogen, and stir at room temperature for 2 h under the protection of nitrogen to thaw to obtain a mixed solution;

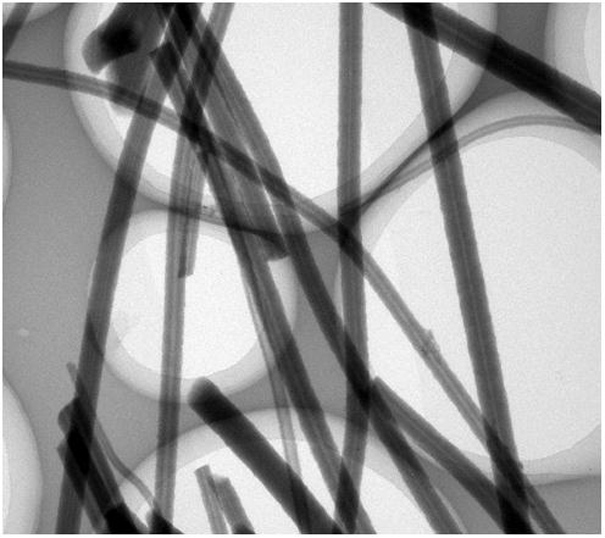

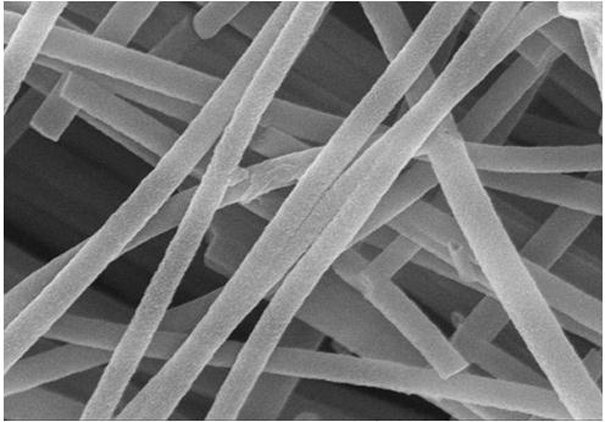

[0041] (c) The temperature of the reaction system in step (b) was raised to 80°C, and transferred to an oven for 72 h. After the reaction is completed, the product is washed with chloroform, methanol, acetone, and ethyl acetate in sequence, and dried to obtain a hollow tubular organic porous poly...

Embodiment 1

[0045] The present embodiment provides a kind of preparation method of hollow nanotube 1 catalyst, and it comprises the following steps:

[0046] (a) Catalyst Pd(PPh 3 ) 2 Cl 2 (0.07 mmol 50 mg) and CuI (0.13 mmol, 25 mg) were added to a round bottom flask, and then 1,3,5-triethynylbenzene (1 mmol, 150 mg) and 2,5-dibromo-TEMPO (0.67 mmol, 288.7 mg), pumped and vented 4 times, and vacuumed for 2 h;

[0047] (b) Add triethylamine (3.75 mL) and toluene (3.75 mL) to the reaction system of step (a) under nitrogen, freeze the pumped gas 4 times in liquid nitrogen, and stir at room temperature for 2 h under nitrogen protection to thaw The mixed solution was obtained, the temperature of the reaction system was raised to 80°C, and transferred to an oven for 72 h.

[0048] (c) The product obtained in step (b) was washed sequentially with chloroform, methanol, acetone, and ethyl acetate, filtered to obtain the product, dried in vacuum, and collected to obtain the nitrogen oxide radi...

Embodiment 2

[0055] The present embodiment provides a kind of preparation method of hollow nanotube 2 catalyst, it comprises the following steps:

[0056] (a) Catalyst Pd(PPh 3 ) 2 Cl 2 (50 mg) and CuI (25 mg) were added to a round bottom flask, and then 1,4-diethynylbenzene (1 mmol, 126.15 mg) and 2,5-dibromo-TEMPO (0.5 mmol, 215.5 mg) were added to carry out Pump and exhaust 3-5 times, and vacuum for 2 hours;

[0057] (b) Add triethylamine (3.75 mL) and toluene (3.75 mL) to the reaction system in step (a) under nitrogen, freeze the exhaust gas with liquid nitrogen for 3-5 times, and stir at room temperature for 2 After thawing to obtain the mixed solution, the temperature of the reaction system was raised to 80°C, and transferred to an oven for 72 h.

[0058] (c) The product obtained in step (b) is washed sequentially with chloroform, methanol, acetone and ethyl acetate, filtered to obtain the product, dried and collected to obtain the hollow nanotube 2 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com