Apparatus and method for preventing overheating of exhaust purification filter

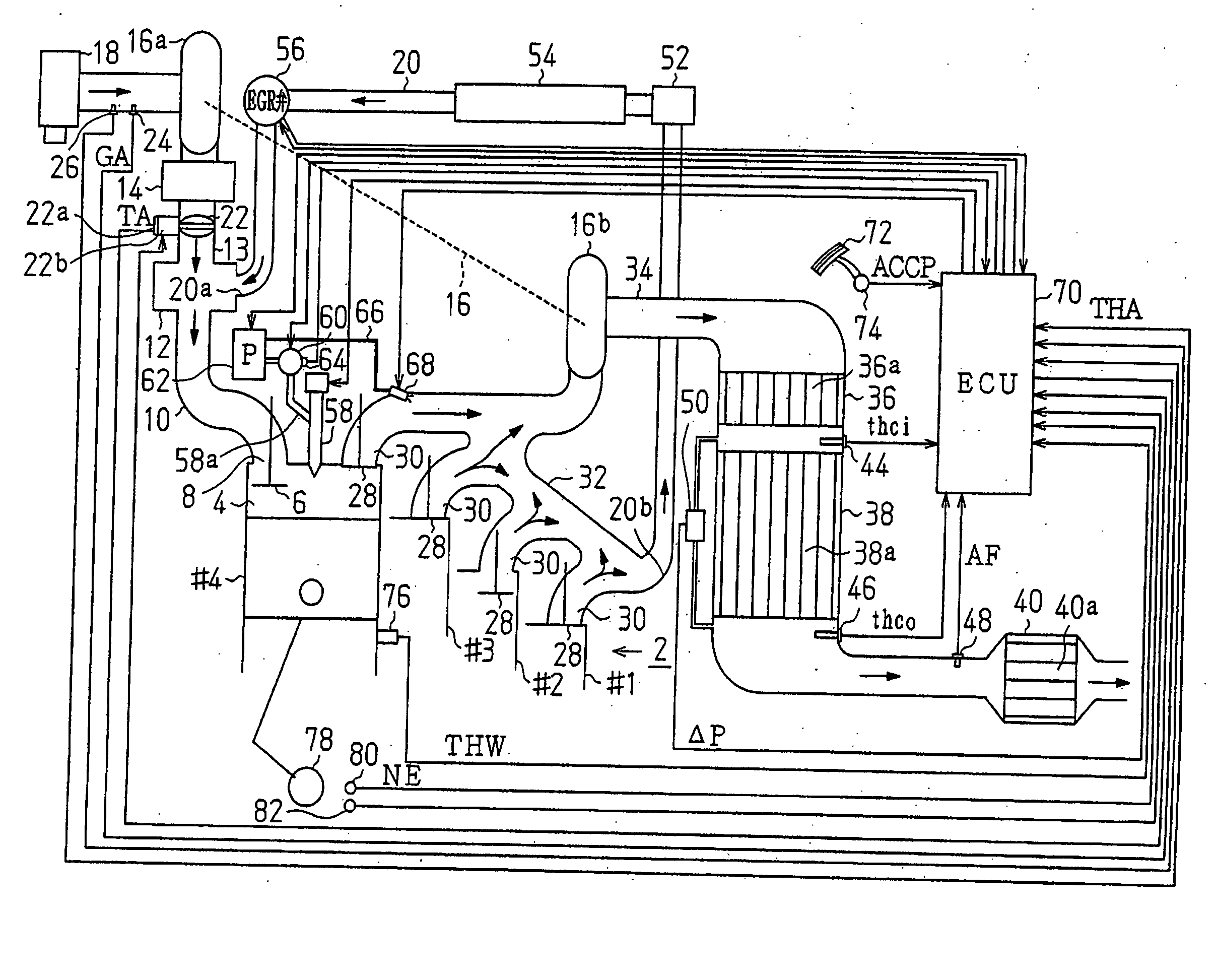

a technology apparatus, which is applied in mechanical apparatus, electrical control, machines/engines, etc., can solve the problems of exhaust purification filter overheating or deterioration, and the exhaust purification filter is more likely to overheat, so as to effectively prevent the exhaust purification filter of an internal combustion engine from overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

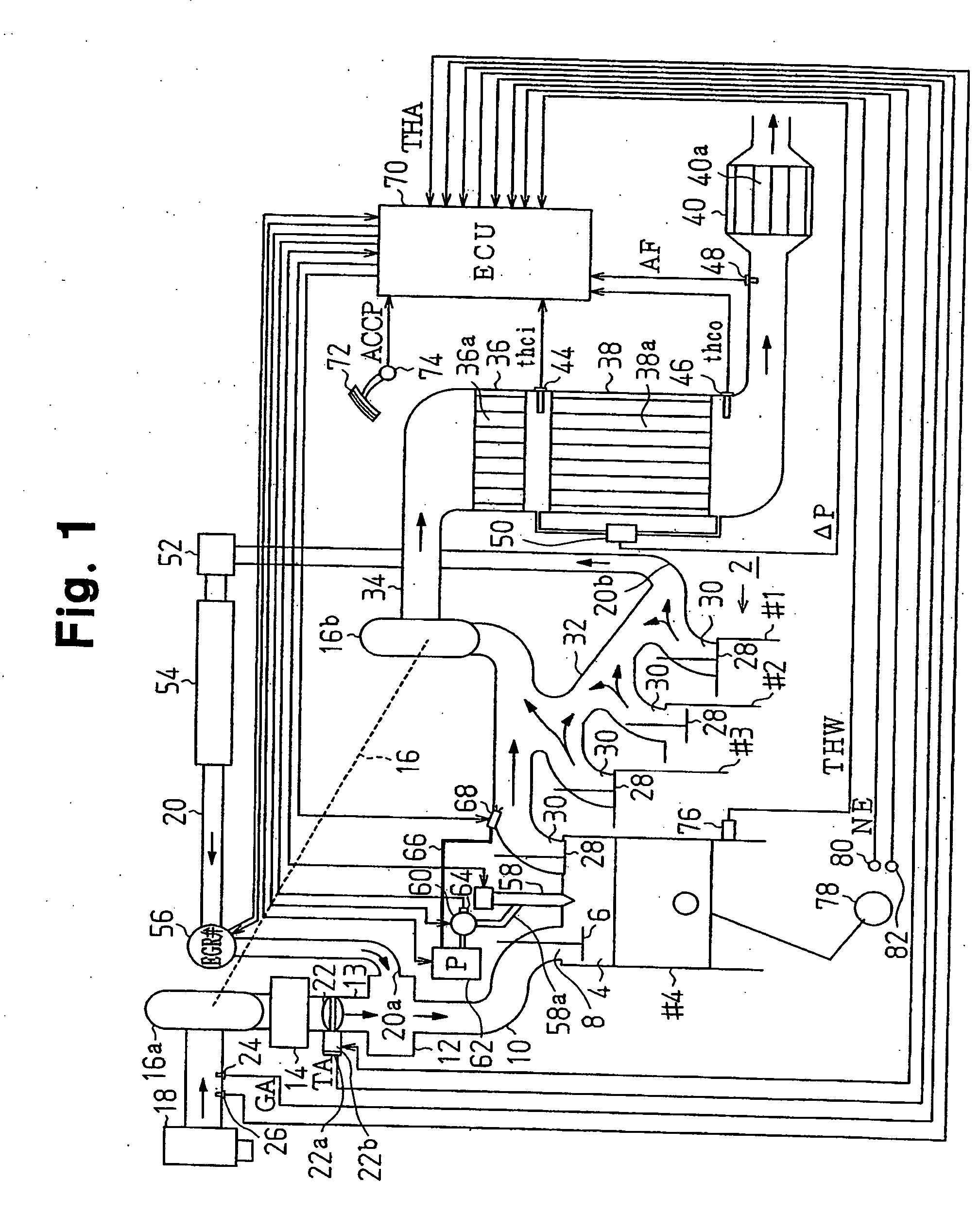

[0084] The first embodiment described above has the following advantages.

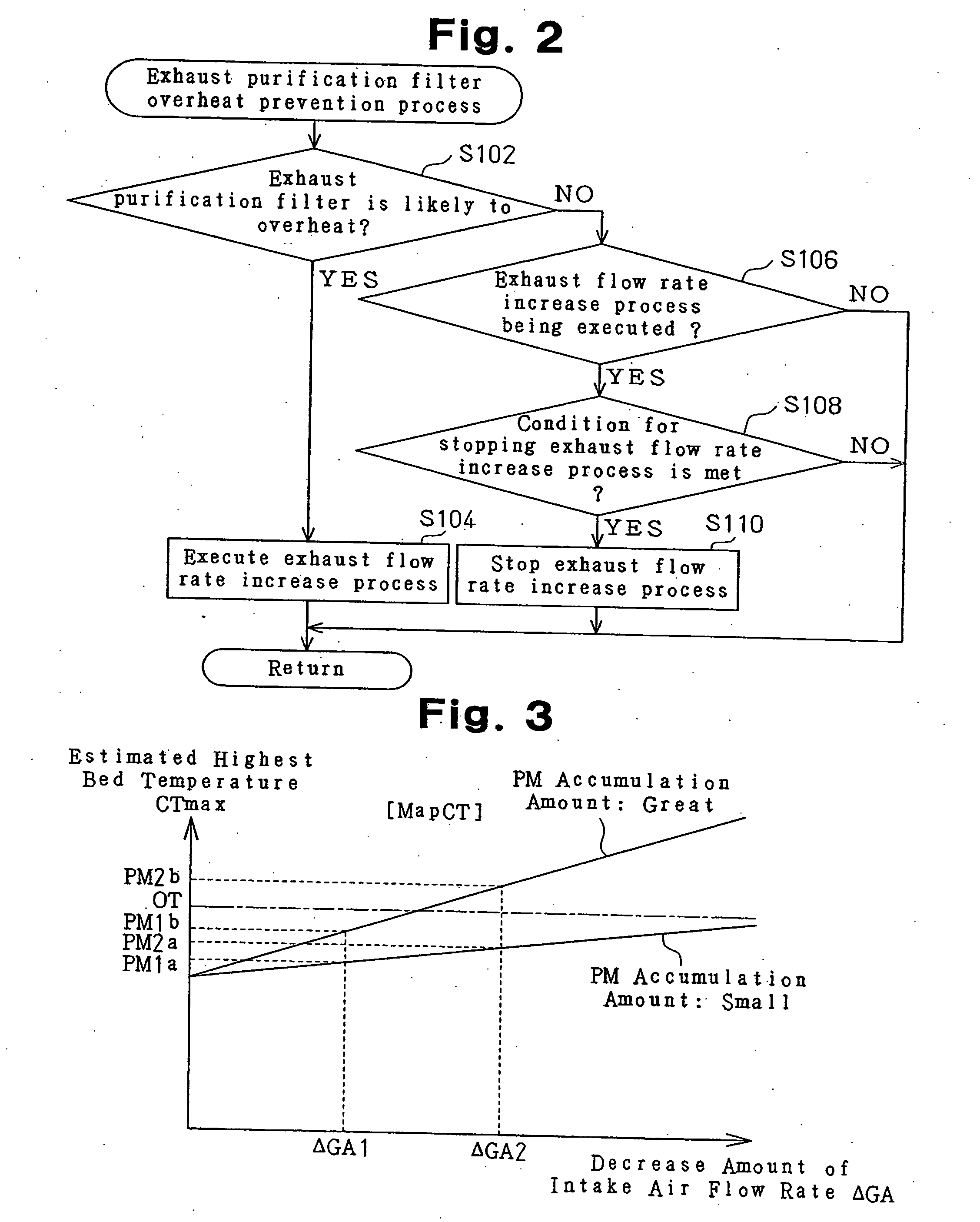

[0085] (A1) In the overheat prevention process of FIG. 2, when the exhaust purification filter 38a is likely to overheat, the throttle valve 22 is fully opened, and the EGR valve 56 is fully closed. Accordingly, the intake flow rate and the exhaust flow rate are increased. Then, when steps S156, S160 of the fuel injection amount control of FIG. 5 are executed, the idle speed is increased during idling. A sufficient exhaust flow rate is thus ensured. Therefore, the heat generated in the exhaust purification filter 38a is positively lost to the outside, and the exhaust purification filter 38a is effectively prevented from overheating.

[0086] (A2) Whether the exhaust purification filter 38a is likely to overheat is determined by monitoring whether the expected maximum bed temperature CTmax, which is estimated based on the map MapCT of FIG. 3, exceeds the overheat determination temperature OT based on the intake fl...

second embodiment

[0096] The second embodiment as described above has the following advantages.

[0097] (A1) The second embodiment has the same advantage as the item (A1) of the first embodiment.

[0098] (A2) Whether the exhaust purification filter 38.a is likely to overheat is determined based on the upstream exhaust temperature thci detected by the first exhaust temperature sensor 44 and the downstream exhaust temperature thco detected by the second exhaust temperature sensor 46.

[0099] The temperature of the exhaust purification filter 38a is affected by the temperature of exhaust gas that flows into the filter 38a. Therefore, whether the exhaust purification filter 38a is likely to overheat can be determined by determining the upstream exhaust temperature thci of the exhaust purification filter 38a.

[0100] Particularly, the NOx storage reduction catalyst 36a, which is another exhaust purification catalyst, is disposed in a section upstream of the exhaust purification filter 38a. The NOx storage redu...

third embodiment

[0115] The third embodiment as described above has the following advantages.

[0116] (A1) The third embodiment has the same advantage as the item (A1) of the first embodiment.

[0117] (A2) Whether the exhaust purification filter 38a is likely to overheat is determined based on the estimated bed temperature thcf estimated based on the intake flow rate GA, the amount of added fuel, and the upstream exhaust temperature thci and the downstream exhaust temperature thco of the exhaust purification filter 38a.

[0118] As a result, overheat of the exhaust purification filter 38a is accurately predicted, and the exhaust flow rate is properly increased. Thus, the exhaust purification filter 38a is effectively prevented from overheating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com