Preparation method of amorphous alloy fiber and device for implementing the preparation method

A technology of amorphous alloy fiber and amorphous alloy, which is applied in the field of preparation of amorphous alloy fiber, can solve the problems of limited area shrinkage of wire material, difficulty in preparing amorphous fiber, large anisotropy of wire material, etc., and achieve cost Low cost, simple structure, simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In the present embodiment, the molecular formula of the amorphous alloy material is (Co 0.5 Fe 0.5 ) 62 Nb 8 B 30 .

[0050] First, the amorphous alloy material is prepared as an amorphous alloy rod, and the preparation method is as follows:

[0051] 1. After the raw materials Co, Fe, Nb and B with a purity of not less than 99.5wt% are prepared in a molar ratio of 31:31:8:30, they are mixed and smelted in an electric arc furnace with an argon atmosphere for 3 to 4 times. After cooling (Co 0.5 Fe 0.5 ) 62 Nb 8 B 30 Master alloy ingot.

[0052] 2. Using a vacuum copper mold casting method, the master alloy ingot was re-melted to obtain a master alloy melt, and then the master alloy melt was sprayed into a copper mold to obtain a bulk amorphous alloy rod sample with a diameter of 1 mm.

[0053] The above-mentioned amorphous alloy rod sample is tested as follows:

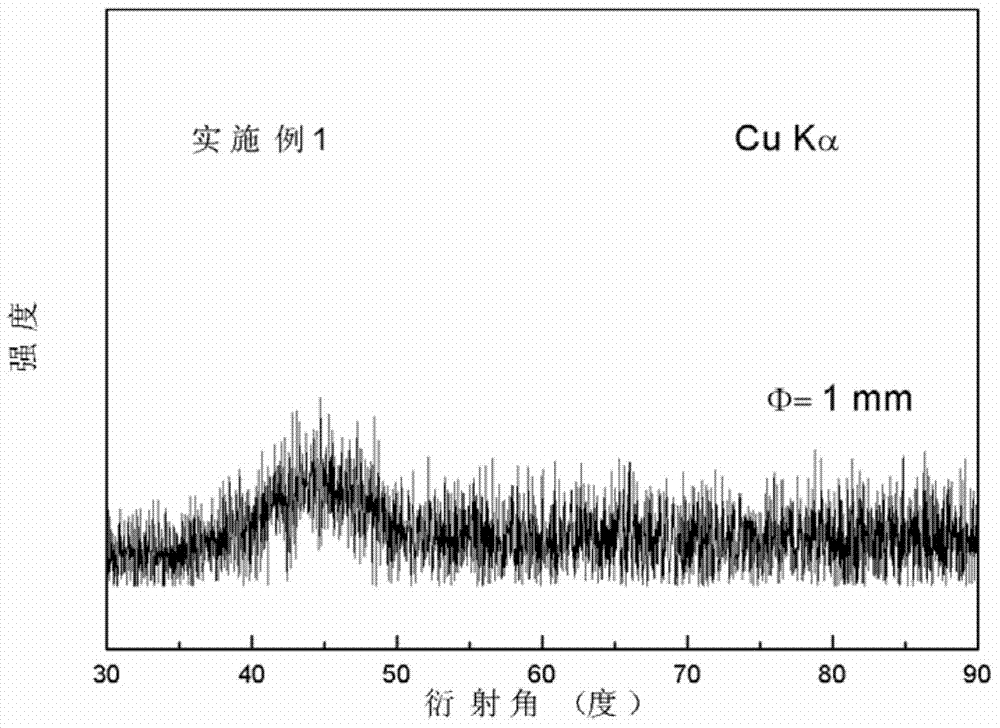

[0054] (1) X-ray diffraction (XRD) was used to analyze the structure of the amorphous alloy rod. S...

Embodiment 2

[0077] In this embodiment, the amorphous alloy material is completely the same as that in Embodiment 1.

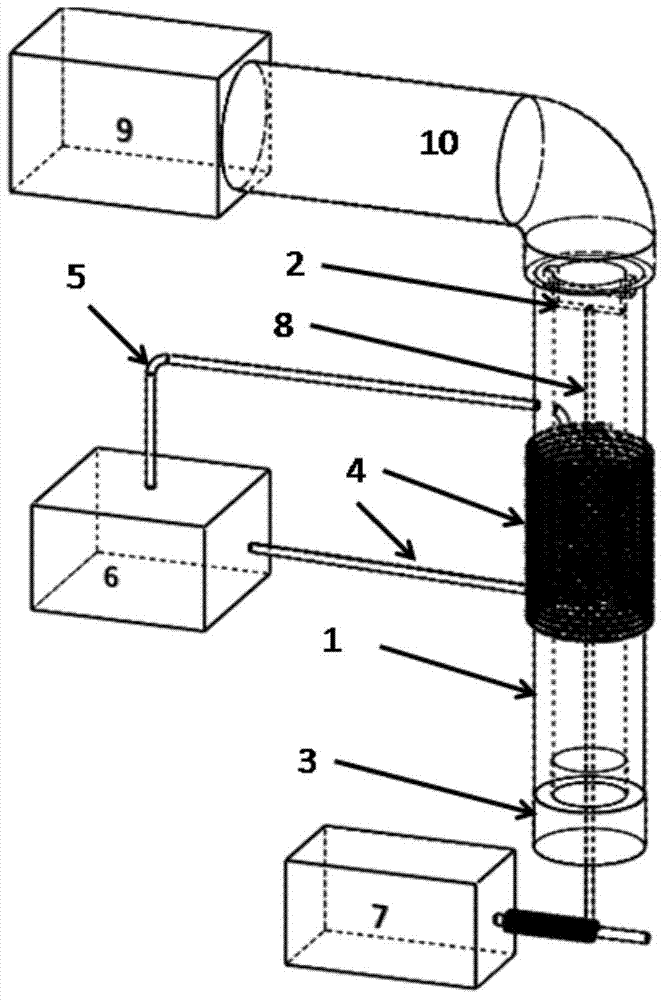

[0078] The superplasticity of the amorphous alloy material is used to prepare the amorphous alloy fiber. Same as embodiment 1, also adopt such as figure 1 The vacuum resistance heating wire drawing equipment shown.

[0079] Firstly, the amorphous alloy material is prepared as an amorphous alloy wire, and the preparation method is exactly the same as that in Example 1.

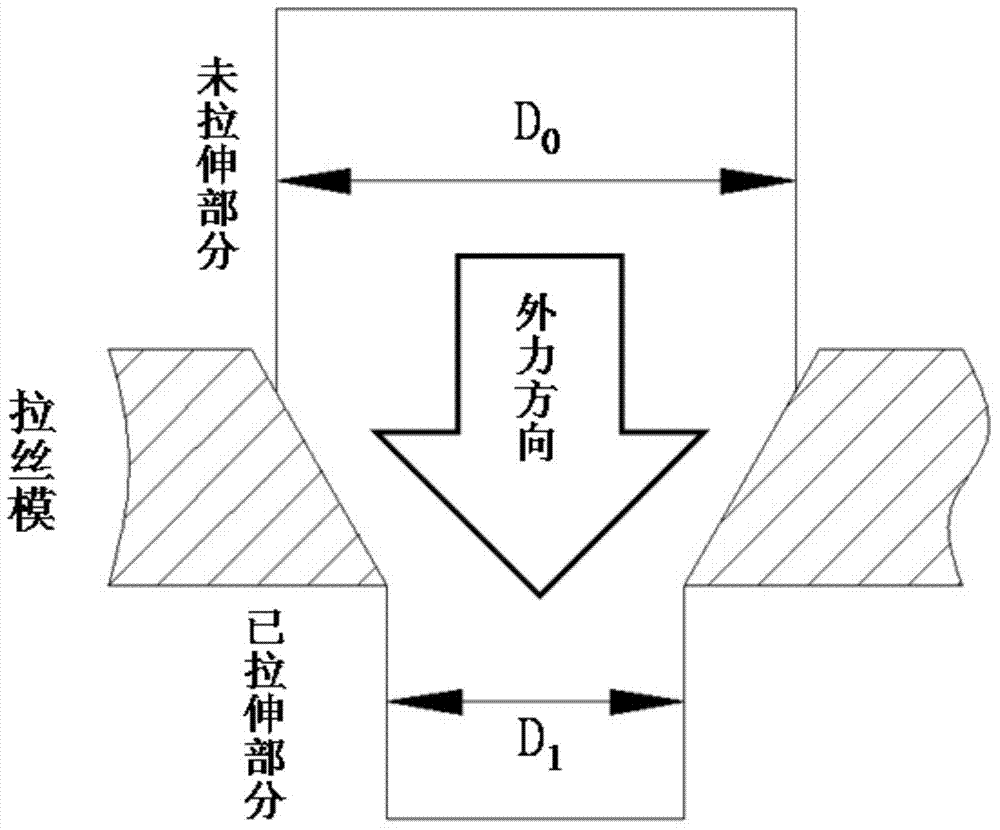

[0080] Different from the examples, in order to control the diameter of the fiber more accurately, a wire drawing die is added in the vacuum resistance heating wire drawing equipment. The diameter of the inner hole of the wire drawing die is 40 μm, and the wire drawing die is fixed in the quartz tube and located in the sealing plug upper part. One end of the amorphous alloy material is fixed by a clamp, and the other end is first corroded and thinned so that its diameter is less than 40 μm, then passes t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com