Temperature rise and fall control method in rapid temperature rise treatment process

A technology of processing process and control method, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve the problem of uncontrollable cooling process, achieve the effect of enriching the range of temperature control, simple implementation, and no cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1 The purpose and execution method of the present invention will be introduced in detail below in conjunction with the accompanying drawings and examples. It is intended to deepen the understanding of the present invention. The following examples should not be regarded as all of the temperature control method of the present invention or as limitations and limitations on the temperature control method technology of the present invention.

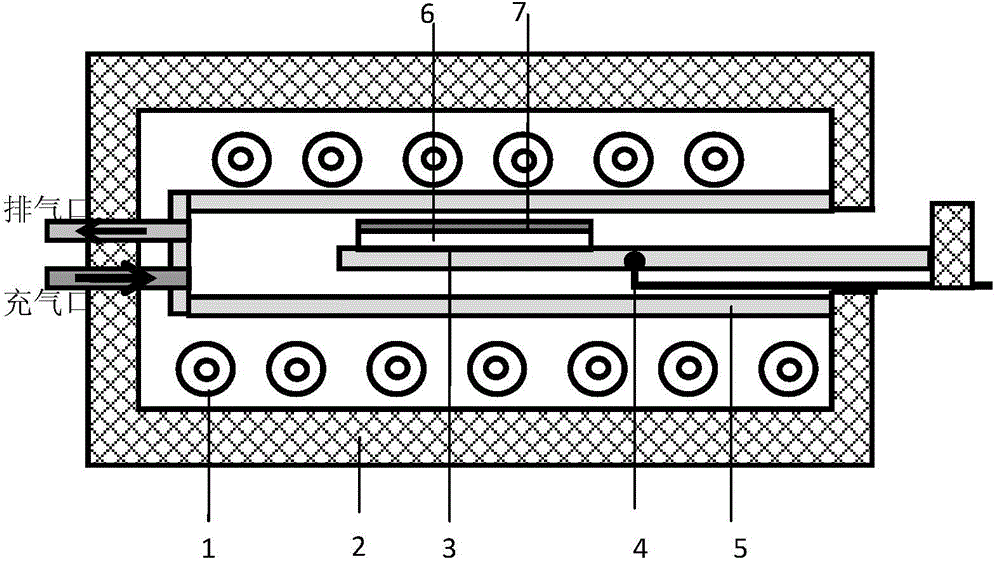

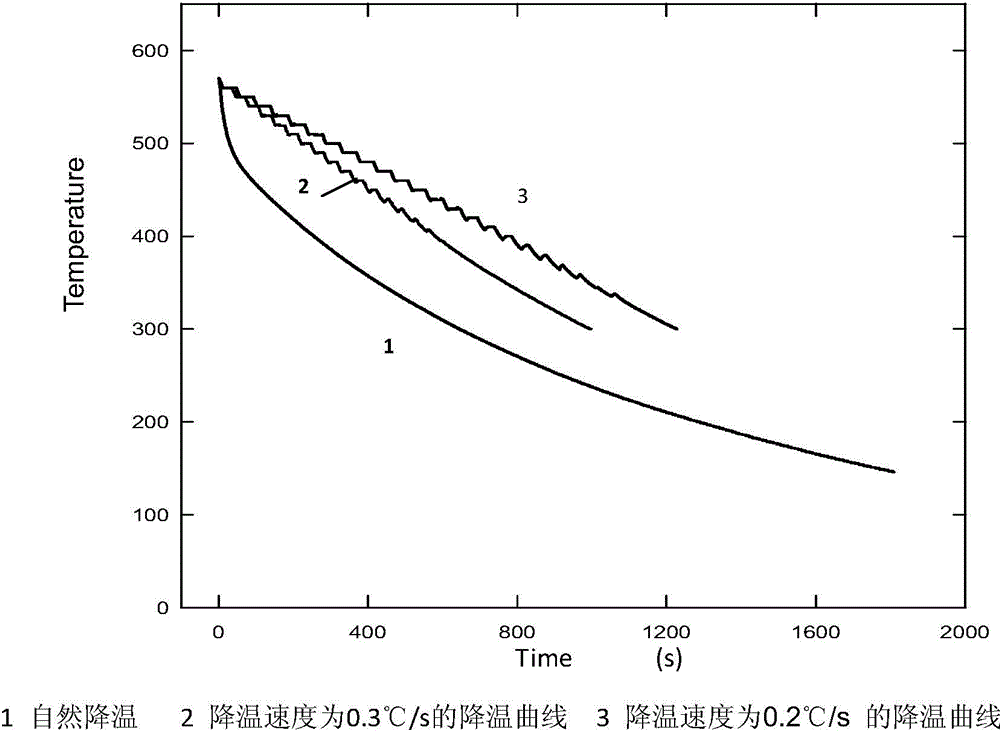

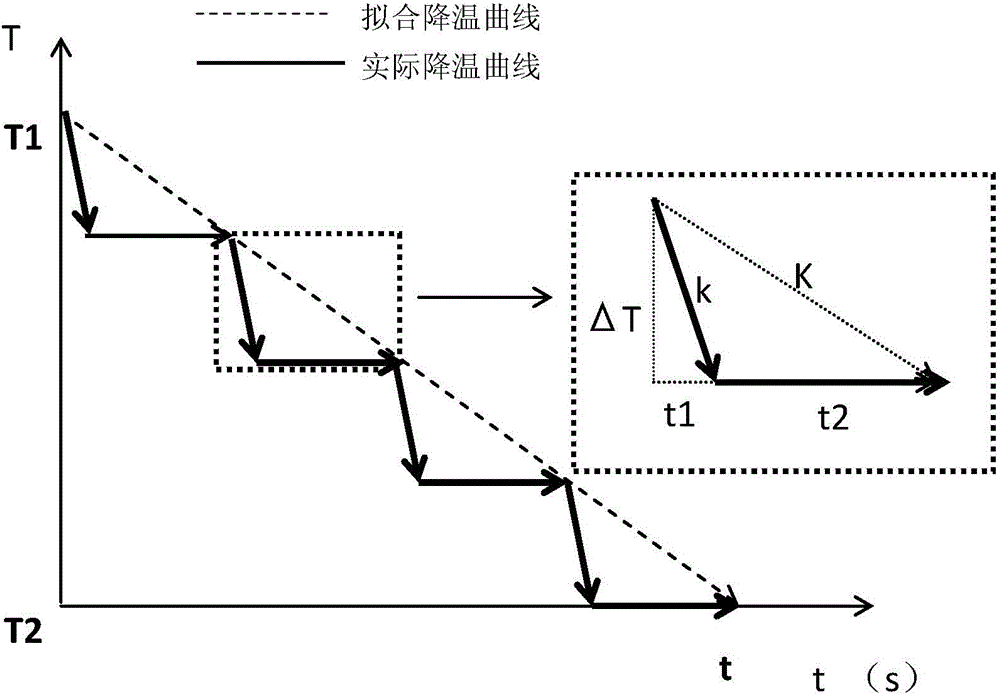

[0020] 2 In this work, the RTP heat treatment process device is used in the cooling process, and the heating chamber is cooled by air cooling. Due to the non-adjustability of air cooling, the only cooling method for the sample and the device itself is determined-natural cooling. Because of this, the optimization work of the heat treatment process is limited. To solve this problem, the invention utilizes the combination of controlling the irradiation of the tungsten-halogen lamp and the cooling of the device system itself to complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com