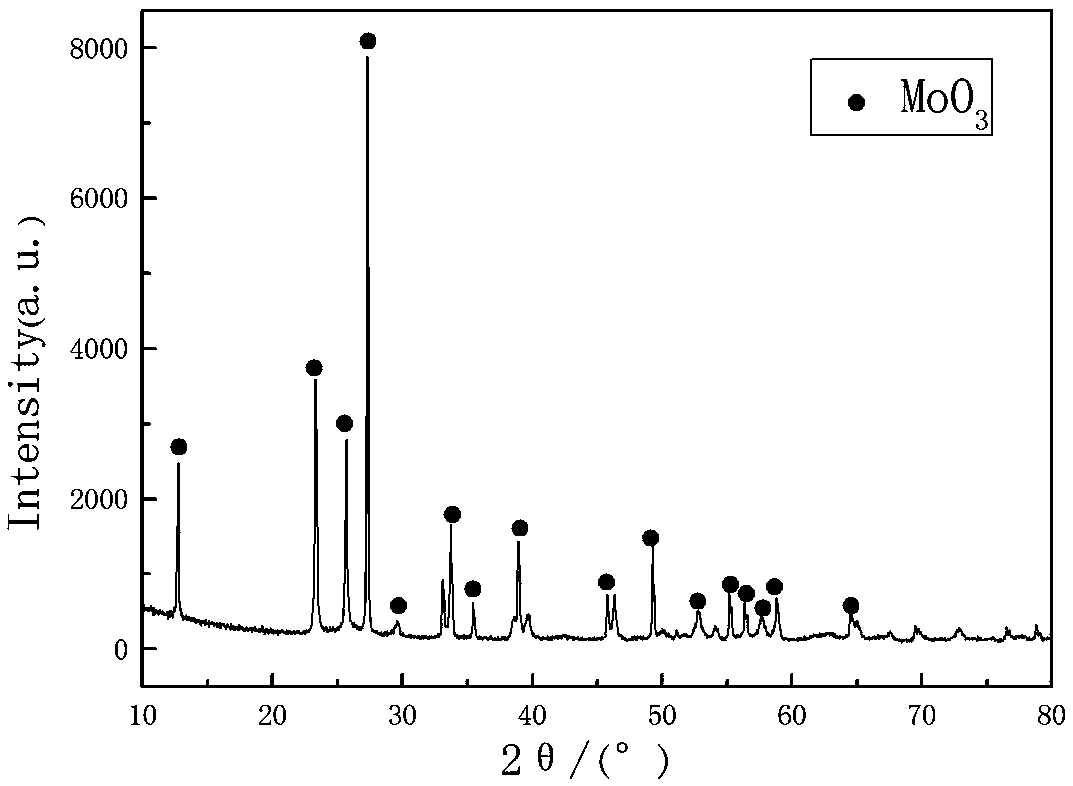

Preparation method of nano MoO3 powder for photocatalytic degradation

A photocatalytic and nanotechnology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of difficult control of product morphology, limited production and application, and high demand for equipment, to achieve Excellent photocatalytic performance, good product stability and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Nano-MoO for photocatalytic degradation 3 The preparation method of powder mainly comprises the following steps:

[0027] Step 1: According to the mass ratio between ammonium tetramolybdate and graphene oxide (60~600): 1 ratio, take a certain amount of graphene oxide solution and ammonium tetramolybdate to fully mix and stir at room temperature , to obtain mixed solution A, for subsequent use;

[0028] The concentration of the graphite oxide solution is 0.5-50 mg / mL, the stirring rate is 600-1200 rpm, and the stirring time is 25-35min. Here, the rate of stirring needs to be limited, because too fast stirring will destroy the graphene oxide sheet structure, making it too dispersed to form a flake shape, and too slow stirring will reduce the combination of graphene oxide and ammonium tetramolybdate properties, so that the template function of graphene oxide cannot be fully exerted.

[0029] Step 2: Put the mixed solution A under vacuum condition for 2~12h and then take...

Embodiment 1

[0036] (1) Take 100 mL of graphene oxide solution with a concentration of 0.5 mg / mL and 0.01 mol of ammonium tetramolybdate (ammonium tetramolybdate: graphene oxide mass ratio = 600:1) and fully mix and stir at room temperature, The stirring rate was 600 rpm, and the mixture was stirred for 30 minutes to prepare a mixed solution A for later use.

[0037] (2) The mixed solution A was placed under vacuum for 2 hours and then taken out to obtain the mixed solution B.

[0038] (3) Quickly freeze the mixed solution B with liquid nitrogen, and then put it into the freezer of the refrigerator for cryopreservation at -2°C for 2 hours to obtain a solid mixture C.

[0039] (4) Put the obtained solid mixture C into a freeze dryer, control the temperature of the cold trap at -60° C., and carry out freeze-drying for 2 hours under the condition of a vacuum of 9 Pa to obtain a dry mixture D for later use;

[0040] (5) Put the prepared dry mixture D into a muffle furnace, control the tempera...

Embodiment 2

[0044] (1) Take 100 mL of graphene oxide solution with a concentration of 50 mg / mL and 0.001 mol of ammonium tetramolybdate (ammonium tetramolybdate: graphene oxide mass ratio = 60:1) at room temperature to fully mix and stir, The stirring rate was 1200 rev / min, and the mixture was stirred for 25 minutes to prepare mixed solution A, which was set aside.

[0045] (2) The mixed solution A was placed under vacuum for 12 hours and then taken out to obtain the mixed solution B.

[0046] (3) Quickly freeze the mixed solution B with liquid nitrogen, and then put it into the freezer of the refrigerator for cryopreservation at -20°C for 24 hours to obtain a solid mixture C.

[0047] (4) Put the obtained solid mixture C into a freeze dryer, control the temperature of the cold trap at -70°C, and carry out freeze-drying for 12 hours under the conditions of a vacuum of 10 Pa to obtain a dry mixture D for use;

[0048] (5) Put the prepared dry mixture D into a muffle furnace, control the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com