Method for roasting and starting aluminum electrolytic cell

A roasting start-up and aluminum electrolytic cell technology, which is applied in the field of aluminum electrolytic cell roasting start-up, can solve the problems of long roasting time, difficult roasting process control, and high production cost of special-shaped carbon block aluminum electrolytic cells, and achieves shortened roasting time and process control. Safe and reliable, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

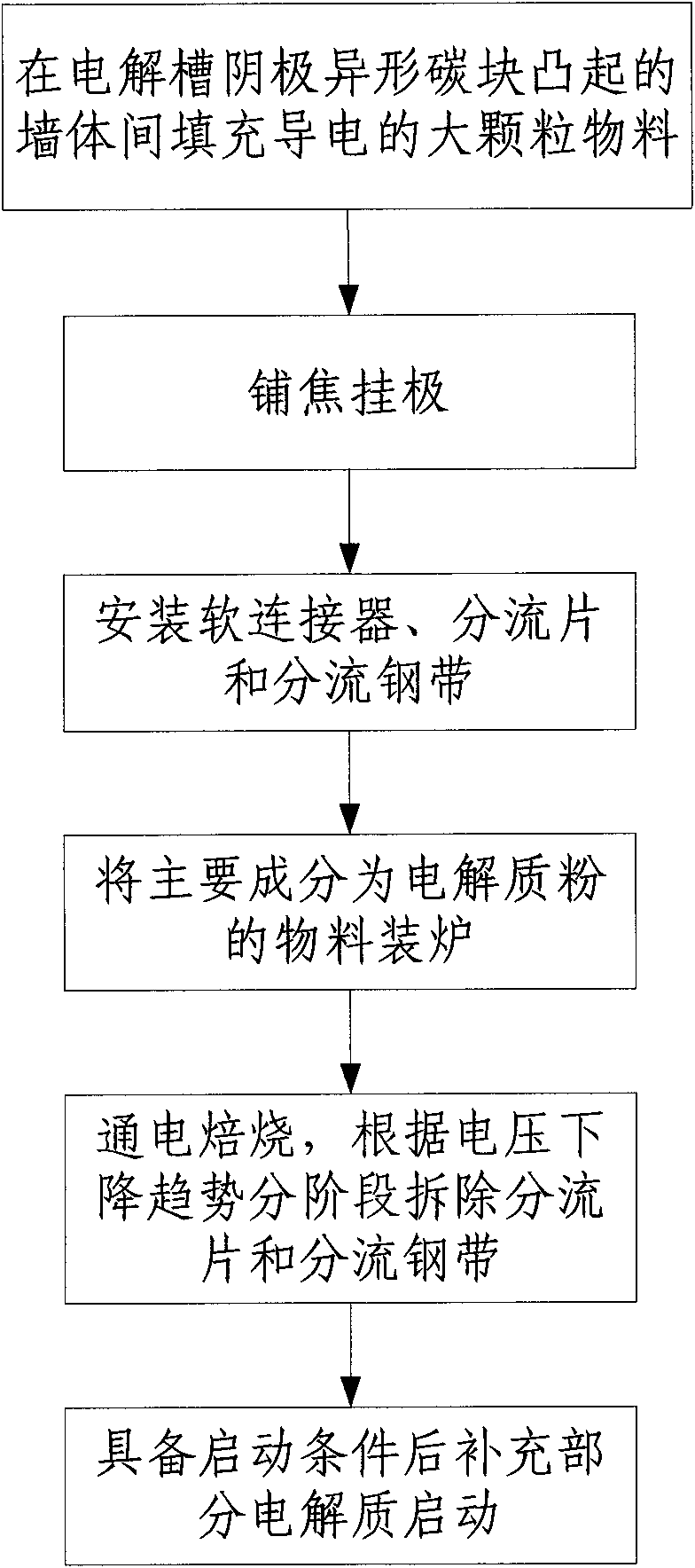

[0013] The flow chart of the aluminum electrolytic cell roasting starting method of the embodiment of the present invention is as follows figure 1 shown, including the following steps:

[0014] Step 1, filling conductive large particle materials between the raised walls of the cathode special-shaped carbon block of the electrolytic cell. The conductive large particle material is evenly and densely filled between the raised walls of the special-shaped carbon block in the cathode of the electrolytic cell. The gap between the large particle material is filled with coke particles, and the filling height of the large particle material is equal to the wall of the special-shaped ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com