Dyeing method of polyester-polyamide composite silk fabric

A polyester-nylon composite yarn and dyeing method technology, applied in the direction of dyeing method, textile and papermaking, etc., can solve the problems of imperfect dyeing process, poor dyeability and poor color fastness of polyester-nylon composite yarn fabrics, and improve the color fastness. The effect of high color fastness, high color fastness and full color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

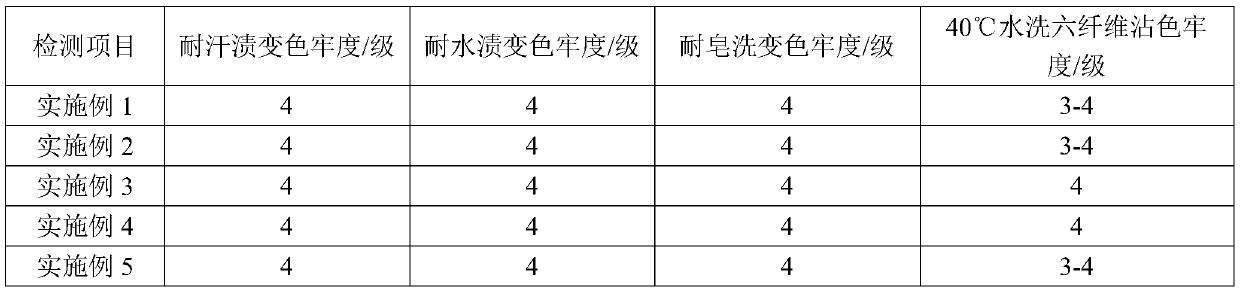

Examples

Embodiment 1

[0053] A method for dyeing polyester-nylon composite silk fabrics, comprising cold-stacking pretreatment, open-width drum vibration washing, overflow tank pre-shrinking, presetting treatment, disperse dyeing, acid overdyeing, and setting treatment.

[0054] Specifically include the following steps:

[0055] (1) Cold stack pretreatment

[0056] Pretreatment working solution: caustic soda 75g / L, hydrogen peroxide 9g / L with a weight fraction of 40%, refining agent TF125L 3.5g / L, chelating agent TF-510T 1g / L;

[0057] Pre-treatment process: Under the condition of temperature of 40°C and vehicle speed of 35m / min, padding is carried out on the fabric, the excess rate is 70%, and then coiled, and then wrapped and sealed with plastic paper, at a temperature of 40°C Under the conditions of stacking, stacking treatment 30h, in the whole process of stacking, keep the rotating speed of stacking at 8r / min;

[0058] (2) Open-width rotary drum vibration washing

[0059] Shock washing work...

Embodiment 2

[0082] A method for dyeing polyester-nylon composite silk fabrics, comprising cold-stacking pretreatment, open-width drum vibration washing, overflow tank pre-shrinking, presetting treatment, disperse dyeing, acid overdyeing, and setting treatment.

[0083] Specifically include the following steps:

[0084] (1) Cold stack pretreatment

[0085] Pretreatment working solution: caustic soda 85g / L, hydrogen peroxide with a weight fraction of 30% 7.5g / L, refining agent TF125L 3g / L, chelating agent TF-510T 1.5g / L;

[0086] Pre-treatment process: Under the condition of temperature of 35°C and vehicle speed of 30m / min, padding is carried out on the fabric, the excess rate is 75%, and then rolled, and then wrapped and sealed with plastic paper, at a temperature of 40°C Under the condition of 28 hours, keep the rotation speed of stacking at 8r / min during the whole process of stacking;

[0087] (2) Open-width rotary drum vibration washing

[0088] Shock washing working fluid: caustic s...

Embodiment 3

[0111] A method for dyeing polyester-nylon composite silk fabrics, comprising cold-stacking pretreatment, open-width drum vibration washing, overflow tank pre-shrinking, presetting treatment, disperse dyeing, acid overdyeing, and setting treatment.

[0112] Specifically include the following steps:

[0113] (1) Cold stack pretreatment

[0114] Pretreatment working solution: caustic soda 80g / L, hydrogen peroxide with a weight fraction of 35% 8g / L, refining agent TF125L 4g / L, chelating agent TF-510T 2g / L;

[0115] Pre-treatment process: Under the condition of temperature of 40°C and vehicle speed of 35m / min, padding is carried out on the fabric, the excess rate is 80%, and then coiled, and then wrapped and sealed with plastic paper, at a temperature of 40°C Under certain conditions, the stacking process was carried out for 24 hours, and during the whole stacking process, the rotating speed of the stacking was kept at 8r / min;

[0116] (2) Open-width rotary drum vibration washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com