Deicing robot based on automatic tensioning type U-shaped heating mechanism

A heating mechanism and robot technology, applied in the installation of cables, electrical components, overhead installation, etc., can solve the problems of limited effect, poor deicing effect, and inability to adjust the distance between the cutter heads of the deicing mechanism, and achieve deicing efficiency. High, good deicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

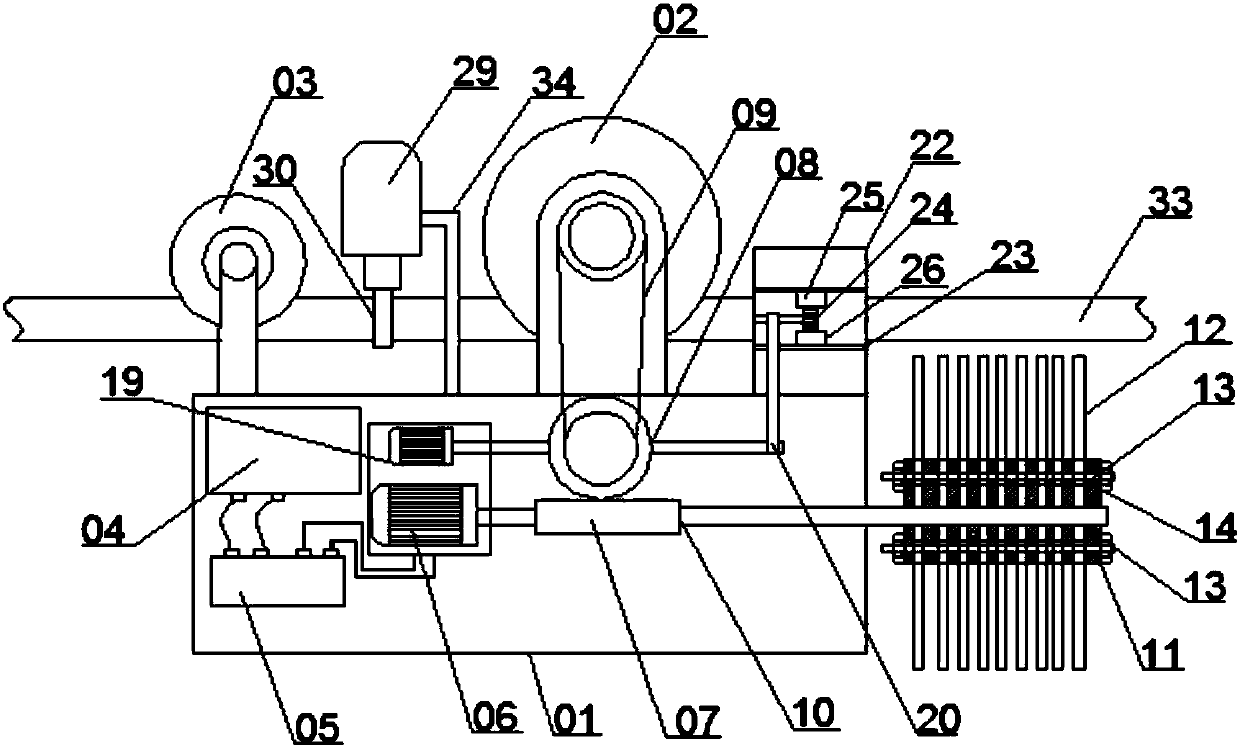

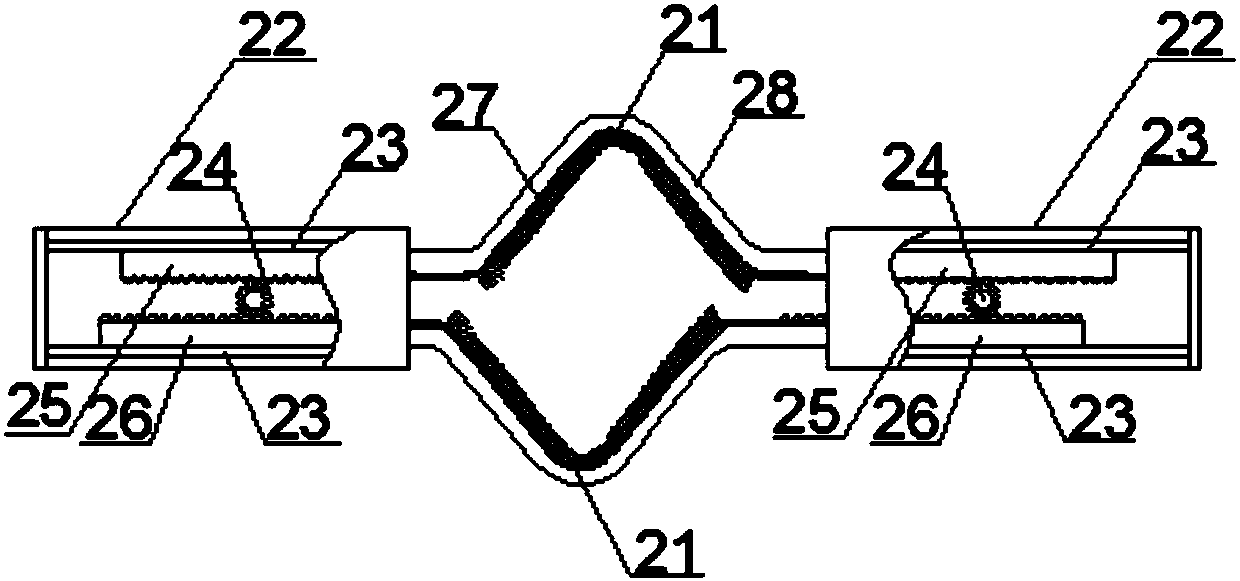

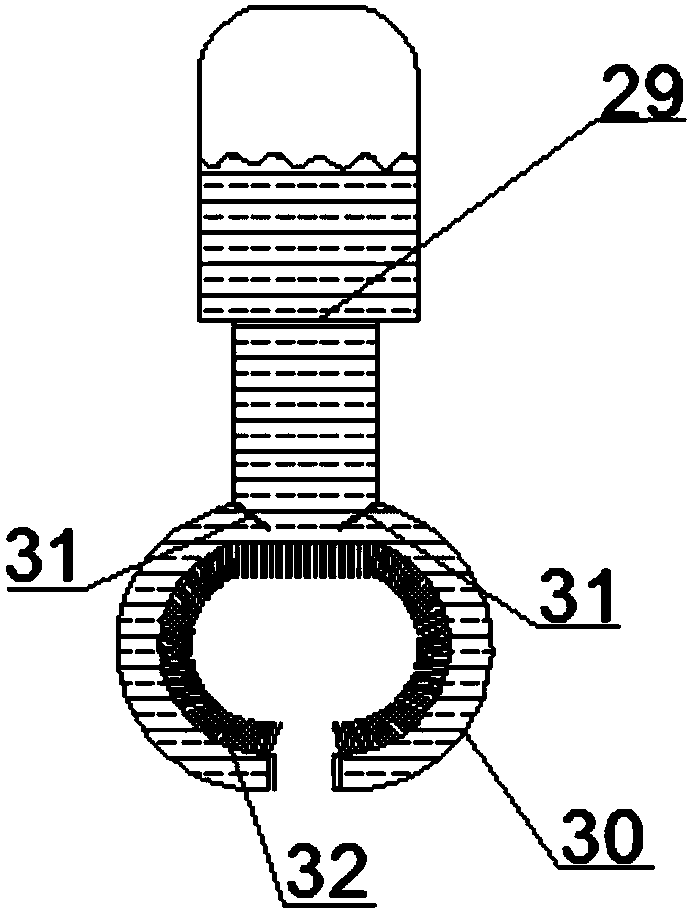

[0034] Please refer to figure 1 As shown, this embodiment provides a deicing robot based on an automatic tensioning U-shaped heating mechanism, including a casing 01, on which a driving wheel 02 and a driven wheel 03 are installed, and on which the driving wheel 02 and the driven wheel 03 are arranged. There is an annular pointed groove, and the transmission line 33 is pressed in the pointed groove, and the whole deicing robot is suspended on the transmission line 33 through the driving wheel 02 and the driven wheel 03. The power storage battery 04 and the controller 05, the casing 01 is provided with a drive motor 06 and a worm gear 07 mechanism, the worm gear 07 is connected to the output shaft of the drive motor 06, the turbine gear 08 is arranged above the worm gear 07 and meshed with the worm gear 07, the turbine gear 08 It is connected with the driving wheel 02 through the transmission belt A09. The front end of the worm 07 protrudes from the casing 01 and is connected w...

Embodiment 2

[0047] Embodiment 2 is basically the same as Embodiment 1, and its difference is: as Figure 6 As shown, the blades 12 on the rotating column 11 are arranged in groups from the front end of the rotating column 11 to the rear end, and each group is arranged on a different level, and each group is composed of 6 strip blades 12 on the same level. °Cross setting, compact structure design, and the crushing efficiency of mechanical ice breaking can be further improved during the rotation process of the rotating column 11.

[0048] In addition, the sharp angle of the pointed groove on the driving wheel 02 and the driven wheel 03 is 60°, and the sharp angle of the pointed groove on the driven wheel 03 is 60°, and an anti-slip groove is provided in the pointed groove Layer 18, on the one hand, prevents the driving wheel 02 and the driven wheel 03 from moving and slipping on the high-voltage transmission line 33; it is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com