Thermal control interface coatings and pigments

a technology of thermal control interface and pigment, applied in the direction of mirrors, thin material processing, instruments, etc., can solve the problems of high cost of the combined electrochemical/chemical oxidation process to obtain the desired surface, inability to select the visible color or appearance of the composite structure, and insufficient radiation control properties of organic paints for some applications, etc., to achieve low chroma and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

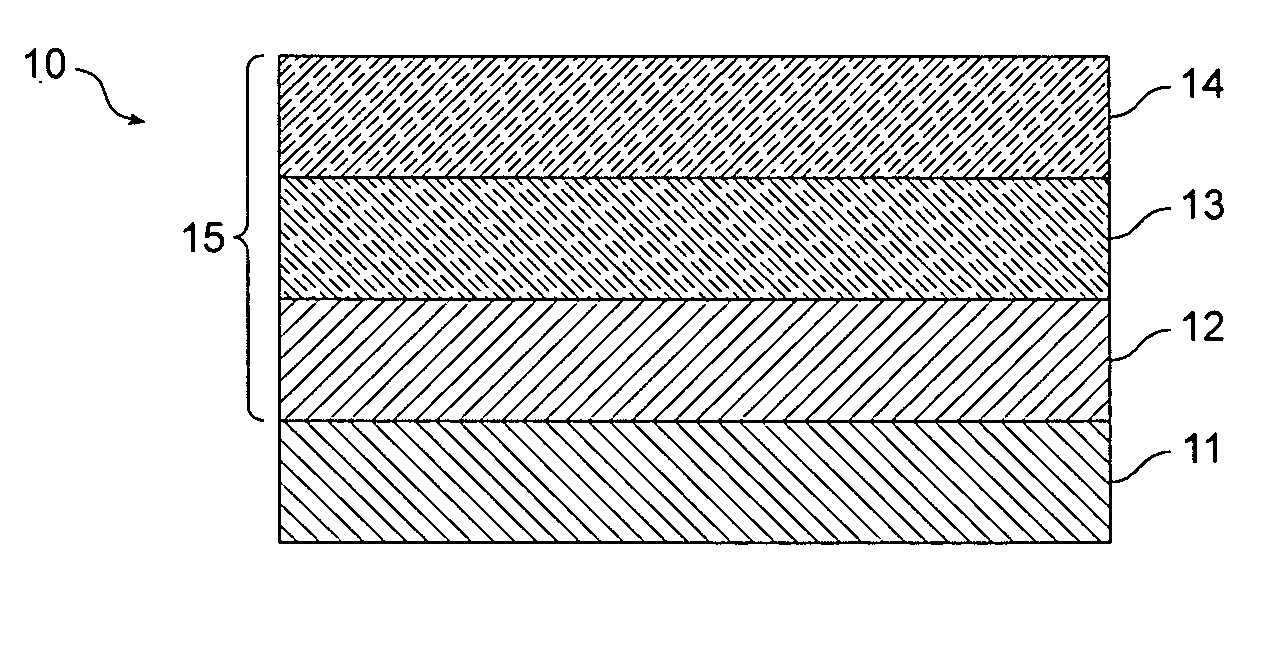

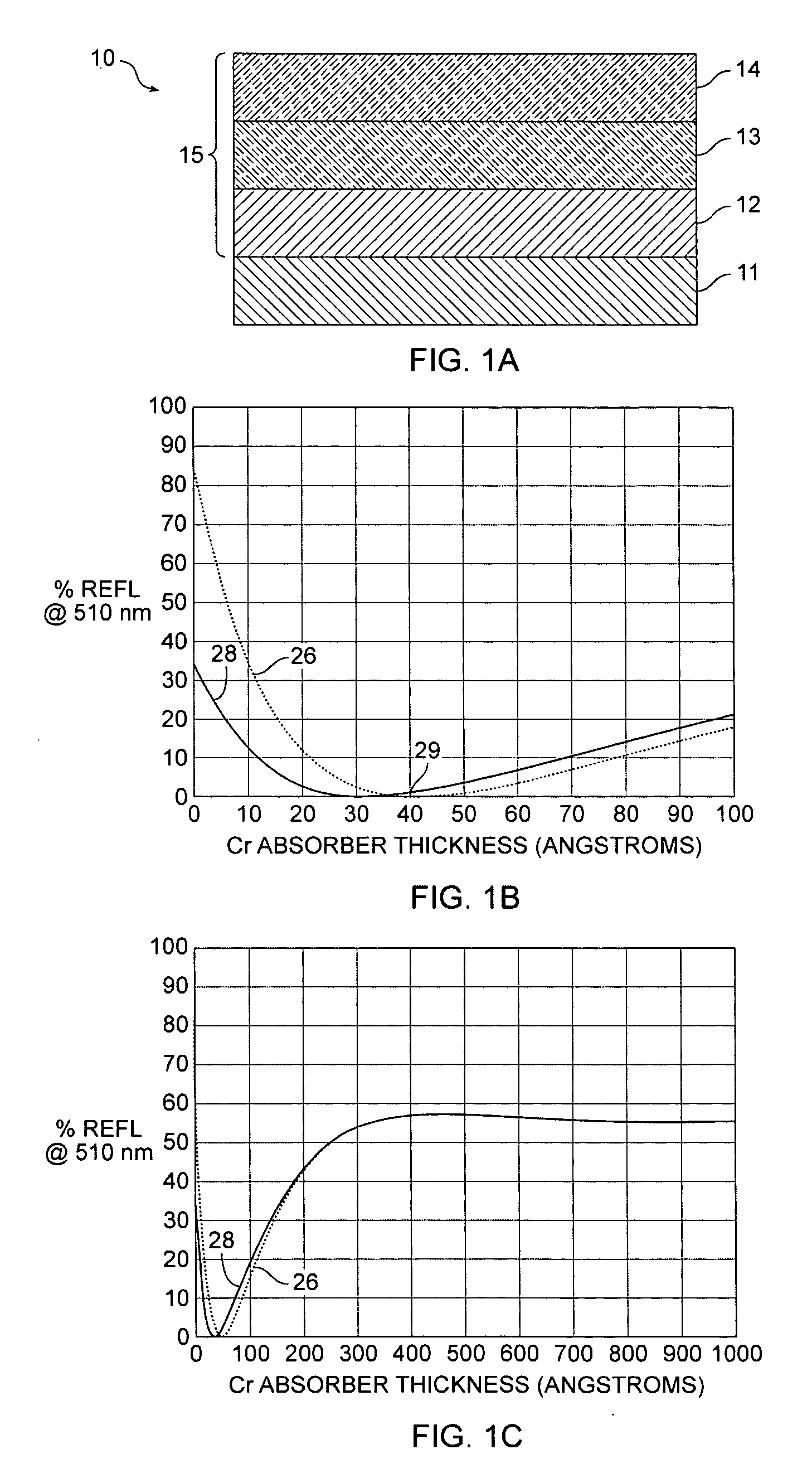

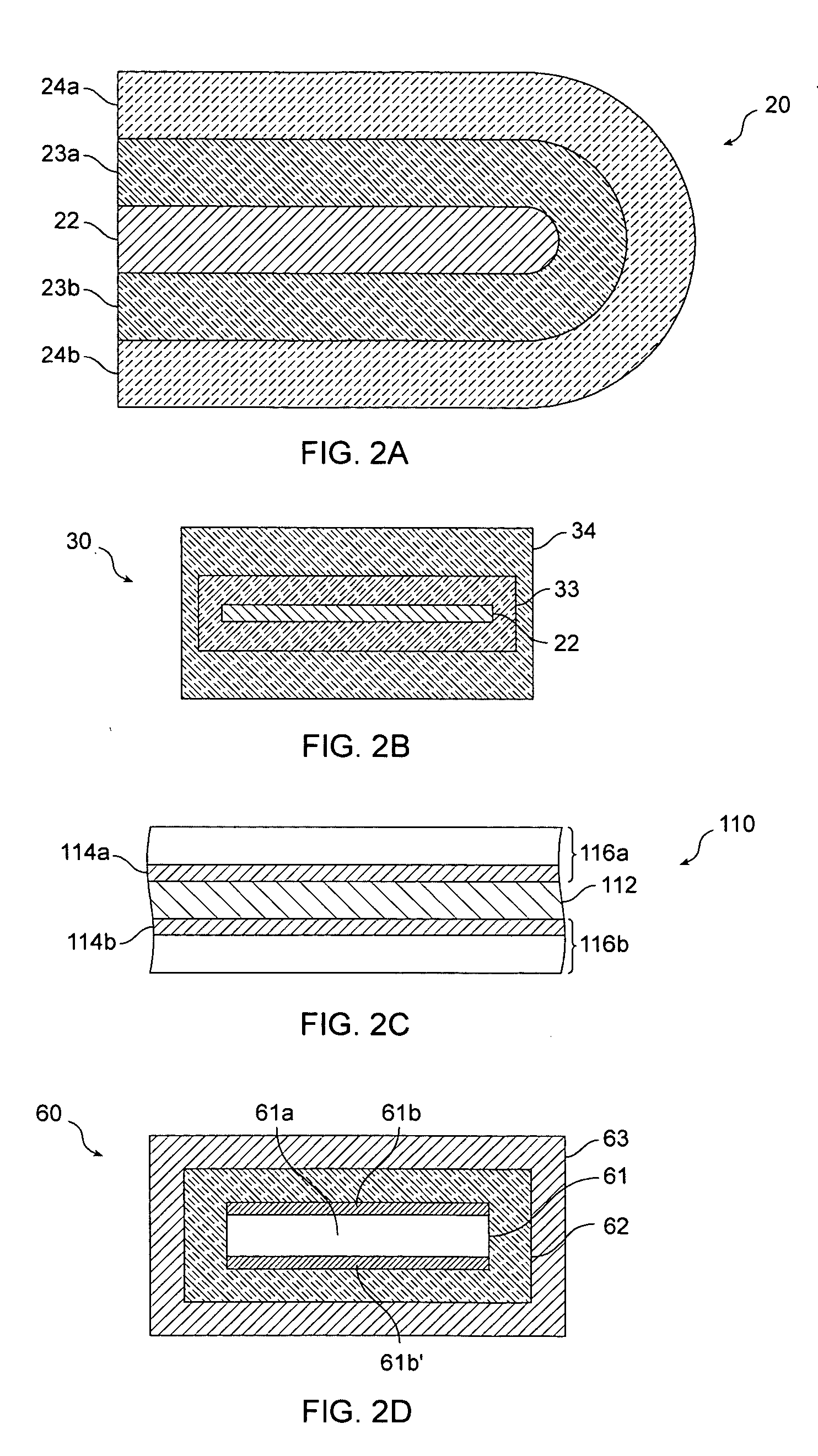

[0042] The present invention relates to optical thin film structures that provide low perceived color and relatively high IR reflectivity. Embodiments of the invention may be embodied as pigment flakes for use in paints, inks, plastic sheets (films), plastic objects, and powder coatings, as foils that are attached to objects, or coatings that are formed directly on objects. In some embodiments, the optical thin film structures appear very dark or even black. Objects coated with pigments, foils, or coatings according to these embodiments of the invention have low perceived color because of the low lightness, even though the measured chroma may be fairly high. In other embodiments, a pigment, foil, or coating appears gray, which may have high lightness in combination with relatively low chroma. In yet other embodiments, the optical thin film structures can be selected to provide a low level of color. Typically, such optical thin film structures exhibit little goniometric color shiftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com