Process for the production of thin semiconductor material films

a technology of semiconductor material and production process, which is applied in the direction of stone-like material working apparatus, instruments, electrical apparatus, etc., can solve the problems of difficult production of monocrystalline films, difficult to produce monocrystalline films, and disadvantages of production procedures for producing thin monocrystalline films, etc., and achieve uniform and controlled thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

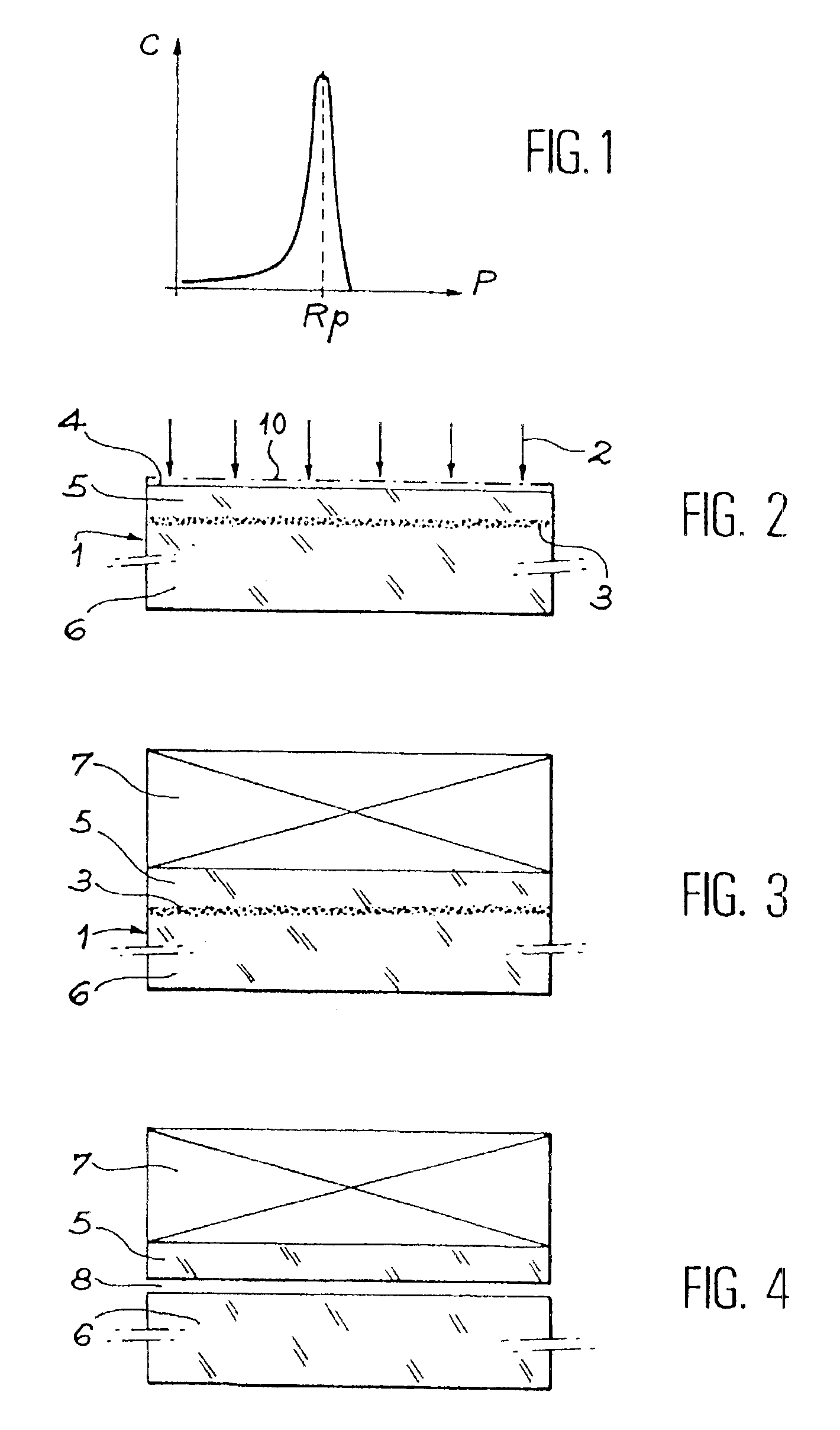

[0033]The embodiment which will now be described in conjunction with the above drawings relates to the production of a thin film in a monocrystalline silicon wafer with the aid of H+ ion implantations.

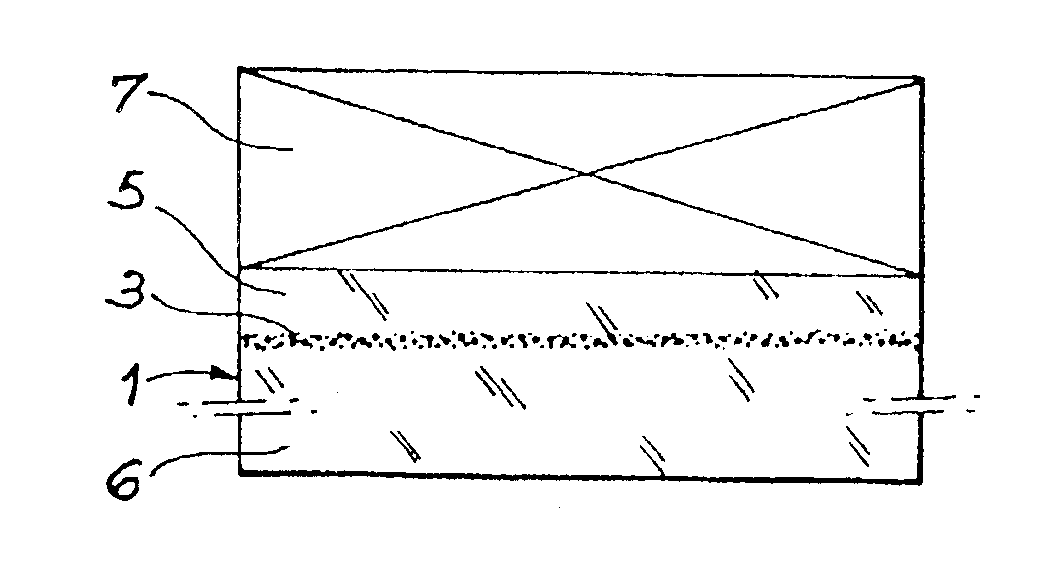

[0034]The implantation of H+ ions (protons) at 150 keV in a monocrystalline silicon wafer, whose surface corresponds to a principle crystallographic plane, e.g. a 1,0,0 plane lead, in the case of weak implantation doses (16 cm−2) to a hydrogen concentration profile C as a function of the depth P having a concentration maximum for a depth Rp, as shown in FIG. 1. In the case of a proton implantation in silicon, Rp is approximately 1.25 micrometers.

[0035]For doses of approximately 1016 cm−2, the implanted hydrogen atoms start to form bubbles, which are distributed in the vicinity of a plane parallel to the surface. The plane of the surface corresponds to a principal crystallographic plane and the same applies with respect to the plane of the microbubbles, which is consequently a cleaving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com