Method for scheduling heliostat of tower type solar energy thermal power station

A technology of tower solar energy and dispatching method, applied in the direction of control/regulation system, control using feedback, instrument, etc., can solve the problem of overheating of heat absorber, achieve the effect of ensuring uniform distribution, improving reliability and avoiding local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

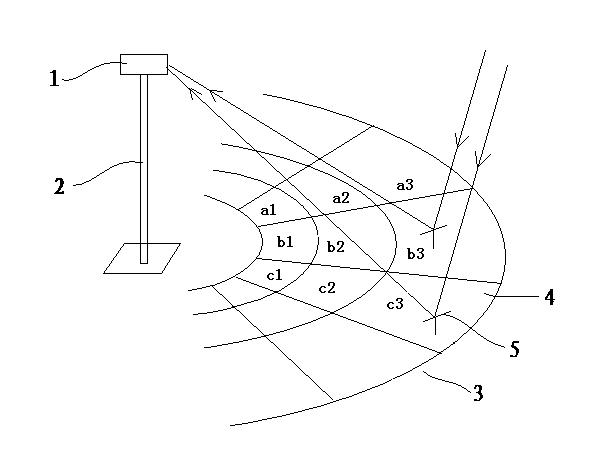

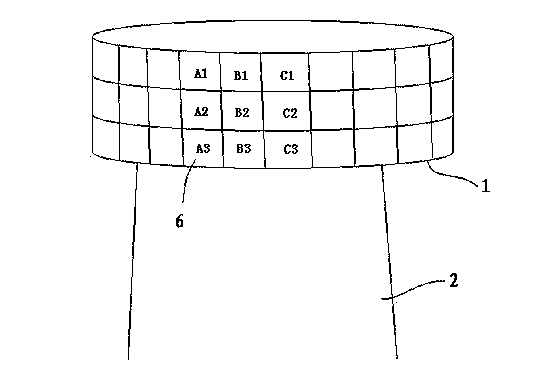

[0017] Embodiment: A method for dispatching heliostats in a tower-type solar thermal power station, such as figure 1 shown. The heat absorber 1 of the tower-type solar thermal power station is installed on the top of the heat collecting tower 2, and the heliostat field 3 is composed of many heliostats, and the heliostats reflect sunlight to the surface of the heat absorber 1. figure 1 Partially shows the division of the mirror field 3, the mirror field 3 is divided into several heliostat groups 4: a1, a2, a3...; b1, b2, b3...; c1, c2, c3.... The heliostats divided into each heliostat group have the same reflection target area on the surface of the heat sink 1 . Correspondingly, such as figure 2 As shown, the surface of the heat absorber 1 is divided into several heat absorbing areas 6: A1, A2, A3...; B1, B2, B3...; C1, C2, C3..., and on the back of each area, set There is a temperature control device.

[0018] The heliostat group 4 and the heat absorption area 6 have a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com