Method for scheduling heliostat field in tower solar thermal power station

A technology of tower-type solar energy and dispatching method, applied in the direction of using feedback control, etc., can solve the problems of large tracking error of heliostat open-loop control, poor energy flow density equalization dispatching effect, and misoperation of hot spots, etc., to achieve It is easy to promote and apply, overcomes the effect of poor energy-flux density homogenization, and is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described below in conjunction with the drawings.

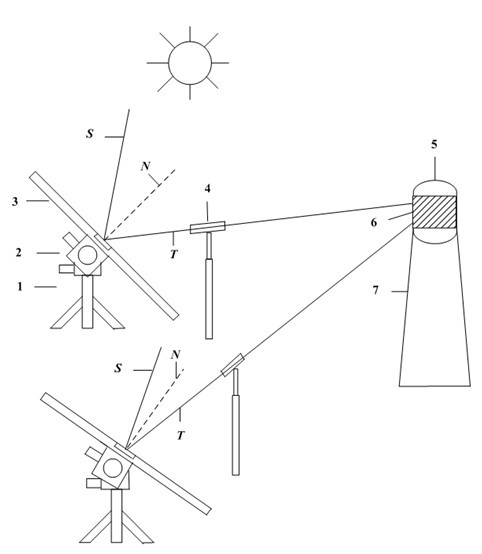

[0023] figure 1 It shows that in a tower solar thermal power station, the entire heliostat field is composed of numerous heliostats 1, and the heliostat tracking controller drives the heliostat actuator 2 to realize the heliostat 1 in two degrees of freedom ( For example, for positioning tracking on azimuth and altitude, or two tilt angles), the heliostat actuator 2 may include a driving device such as an electric motor and a hydraulic mechanism. The heat absorber 5 is placed above the receiving tower 7, and the heat absorber 5 may include a boiler for driving the steam turbine, a molten salt system, a thermochemical reactor, and a device for light-to-heat conversion or solar radiation energy collection. The heat sink receiving surface 6 is the heat sink surface, which is used for receiving and absorbing solar radiant energy, and its form can be flat or curved. The heliostat mirror 3 turns t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com