Spray evaporation treatment method of wet method flue gas desulfurization wastewater in thermal power station

A wet flue gas desulfurization and spray evaporation technology, applied in water/sewage treatment, water/sludge/sewage treatment, separation methods, etc., can solve the problem of reducing flue gas temperature, increasing flue gas humidity, flue and dust collector Corrosion and other problems, to achieve the effect of reducing specific resistance, improving efficiency, and overcoming large corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

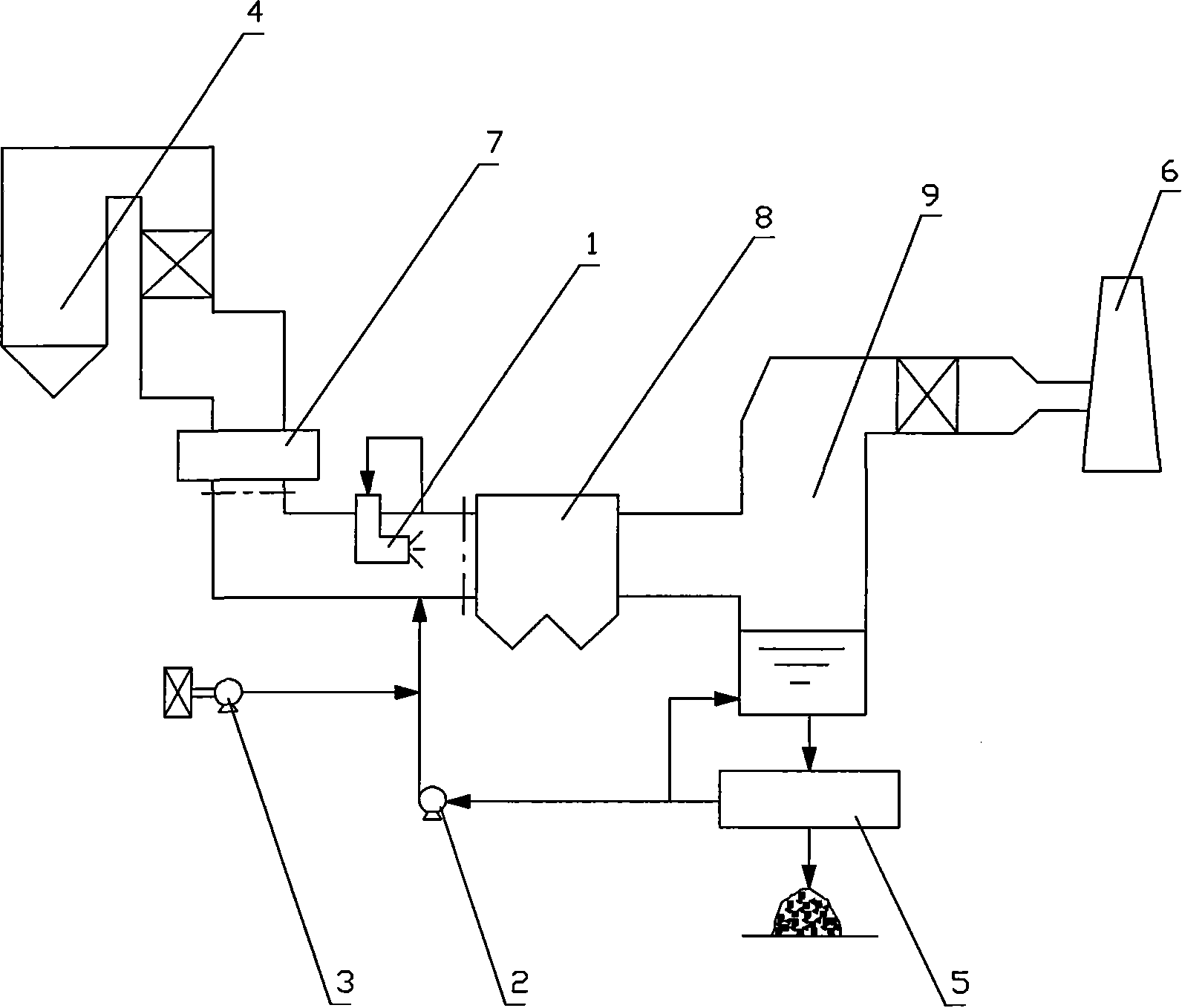

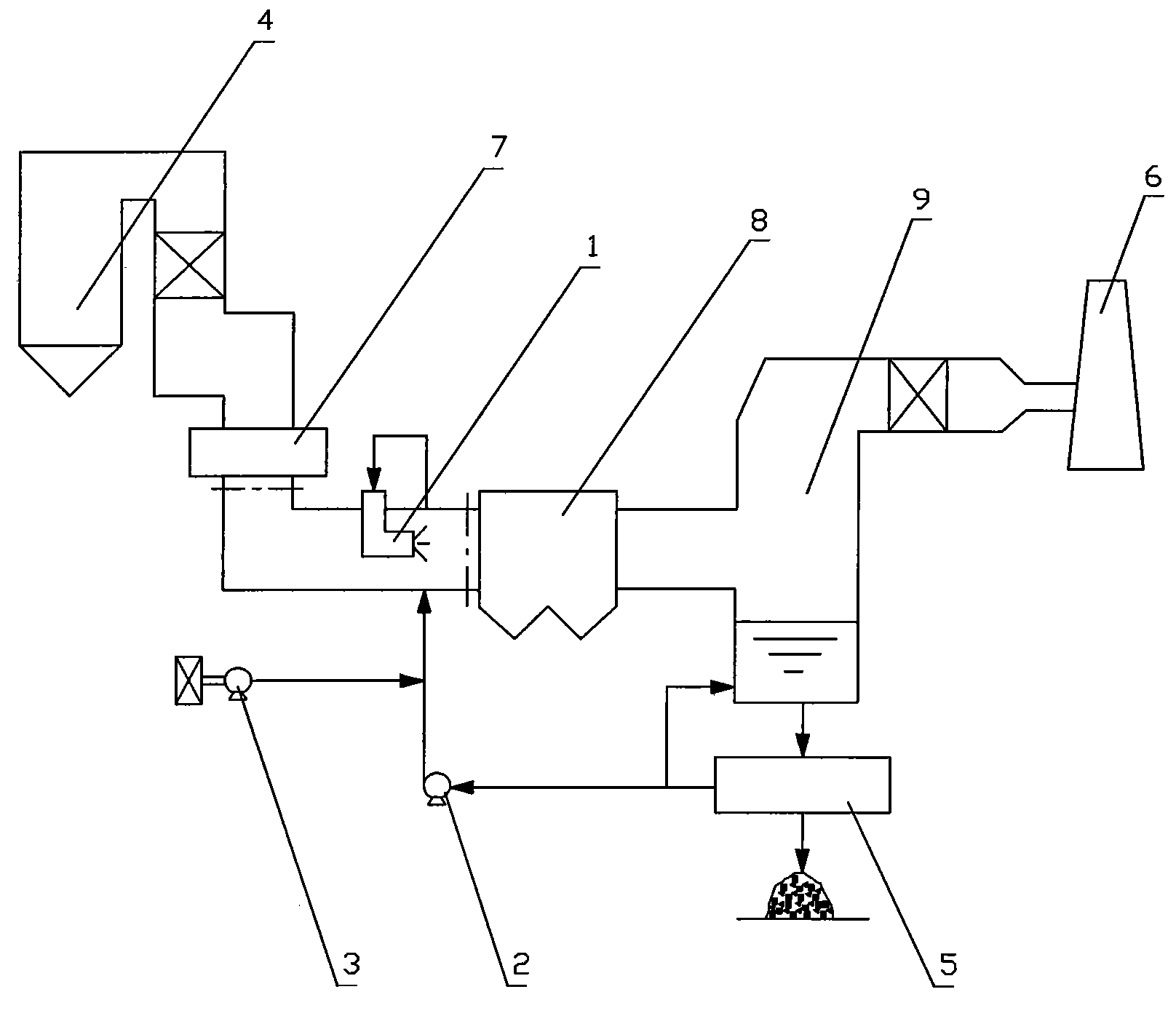

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] In the thermal power plant wet flue gas desulfurization wastewater spray evaporation treatment method, first, a desulfurization wastewater spray evaporation treatment system is installed on the tail flue of the boiler 4, as shown in the figure. Set the atomizing nozzle 1 in the area where the flue gas velocity in the tail flue of boiler 4 is 5-11m / s and the temperature is 413K-470K, and the temperature is higher than the flue gas dew point t 1d , the flue gas dew point is calculated based on the percentage of partial pressure of water vapor and sulfur trioxide in the flue gas, namely:

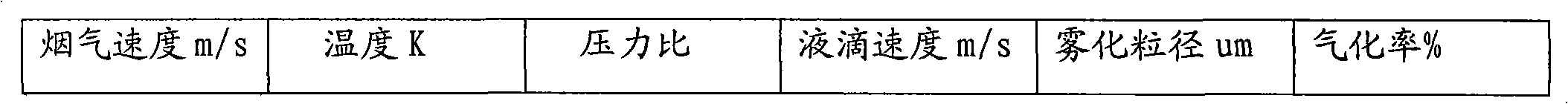

[0019] t 1d =186+201lgH 2 O+26lgSO 3 . Use the water pump 2 to extract the desulfurization wastewater 5 after the exhaust gas is treated by the absorption tower 9, and the air compressor 3 compresses the air; the desulfurization wastewater 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com