Solar energy and coal-burning unit combined thermal power generation system

A thermal power generation system and coal-fired unit technology, applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve problems such as low heat absorption temperature, serious environmental pollution, and reduction of coal mine resources, so as to reduce investment and consumption Coal, the effect of improving thermal economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

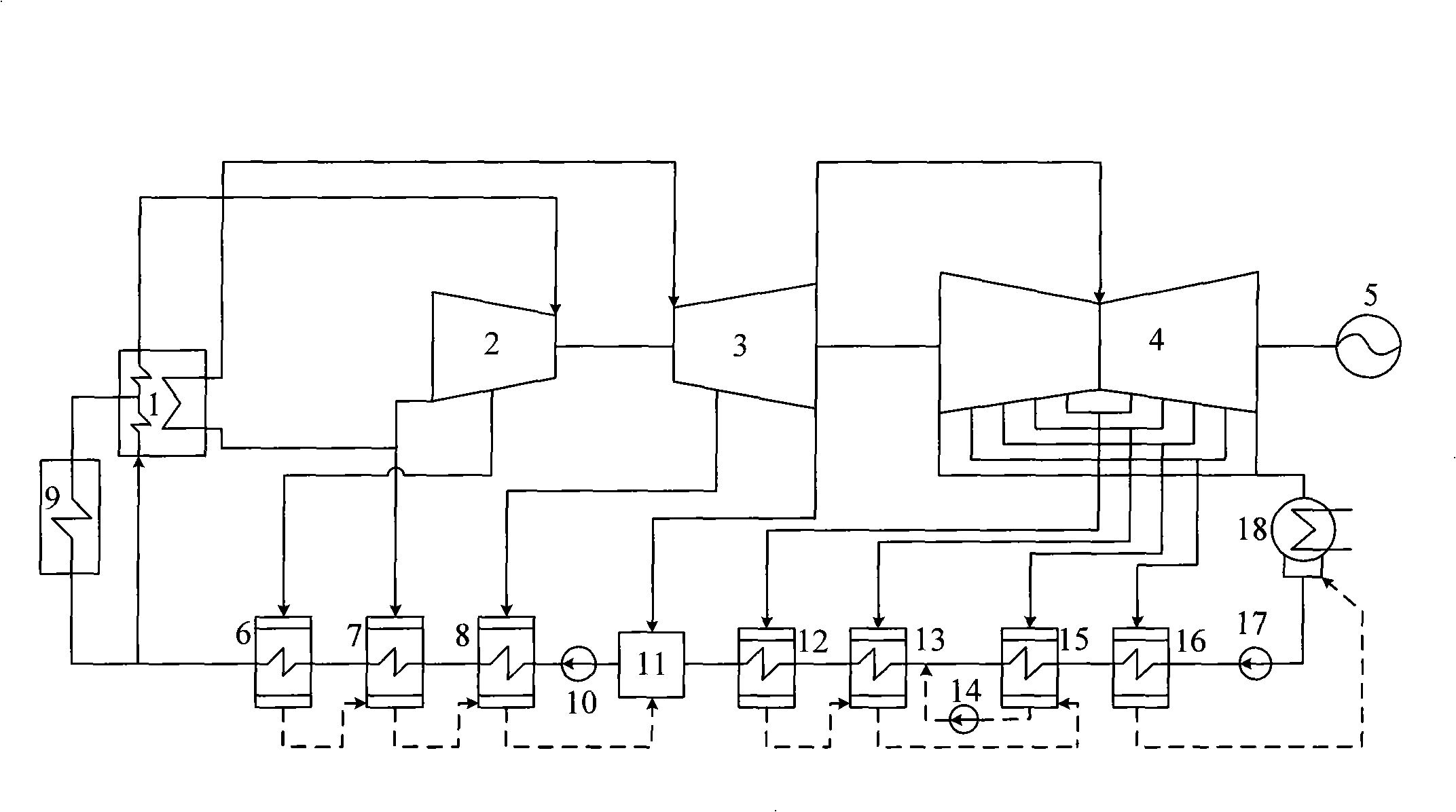

[0016] The present invention provides a thermal power generation system in which solar energy and coal-fired units are mixed. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] figure 1 Shown is a schematic diagram of the system connection of the present invention. The thermal power generation system consists of a coal-fired boiler, a steam turbine, a generator, a heater, a solar heat collector field, a feed water pump, a deaerator, a drain pump, a condensate pump, and a condenser, wherein the solar heat collector field consists of a parabolic The trough solar collectors are connected in series and parallel. The system flow is: the condensed water flowing out of the condenser 18 passes through the condensed water pump 17, and the first-stage low-pressure heater 16, the second-stage low-pressure heater 15, the third-stage low-pressure heater 13, and the fourth-stage low-pressure heater are connected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com