Three-dimensional through-hole or part-hole interconnecting porous metal foam and its preparing method

A three-dimensional through-hole, metal foam technology is applied in the field of porous metal foam materials and their preparation, which can solve the problems of combustion, filter materials cannot be recycled, polluted alloy melts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

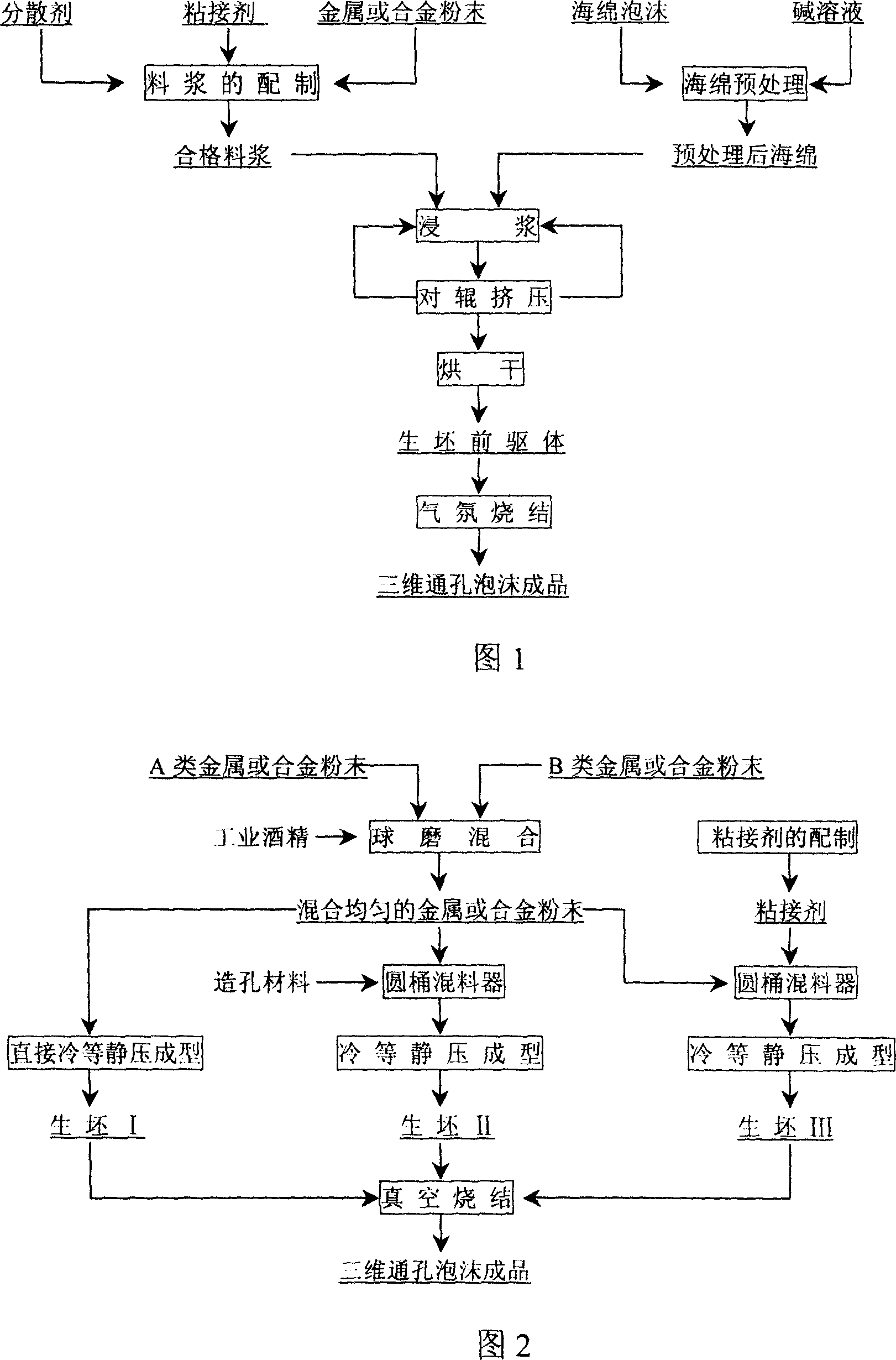

[0035] Preparation of three-dimensional through-hole 316L stainless steel foam with good oxidation resistance and particle trapping performance According to the process shown in Figure 1, three-dimensional through-hole stainless steel foam was prepared.

[0036] Step 1: Preparation of Green Body Precursor

[0037] ① Weigh the raw materials according to the ratio in Table 1, and mix and stir the raw materials in a mixer for 60 minutes to prepare a slurry;

[0038] Table 1 Raw material ratio of precursor slurry

[0039] raw material

Mass percentage (%)

Polyvinyl Alcohol Sol (10%)

Stainless steel powder (316L, 400 mesh)

22

78

[0040] ②Immerse a polyurethane sponge with a sponge foam specification of 20ppi and a diameter of 0.3mm in 10% NaOH solution for 2-4 hours, and then scrub it with clean water to make it hydrophilic;

[0041] ③Immerse the treated polyurethane sponge in the slurry for a period of time, and then squeeze it on the ro...

Embodiment approach 2

[0054] Three-dimensional through-hole 316L / Cr with good high temperature oxidation resistance 2 C 3 Foam Metal Preparation The porous foam material was prepared according to the process flow shown in Fig. 1 .

[0055] Step 1: Preparation of Green Body Precursor

[0056] ① Weigh the raw materials according to the ratio in Table 3, and mix the raw materials in the mixer for 60 minutes to prepare the slurry;

[0057] ②Immerse a polyurethane sponge with a sponge foam specification of 50ppi and a diameter of 0.3mm in 10% NaOH solution for 2-4 hours, and then scrub it with clean water to make it hydrophilic;

[0058] ③Immerse the treated polyurethane sponge in the slurry for a period of time, and then squeeze it on the roller machine to squeeze out the excess slurry; in order to ensure that the slurry is evenly distributed on the sponge foam and reduce hole plugging, this Carried out 5 times of roller extrusion in the embodiment; Adopted roller equipment as shown in Figure 3.

...

Embodiment approach 3

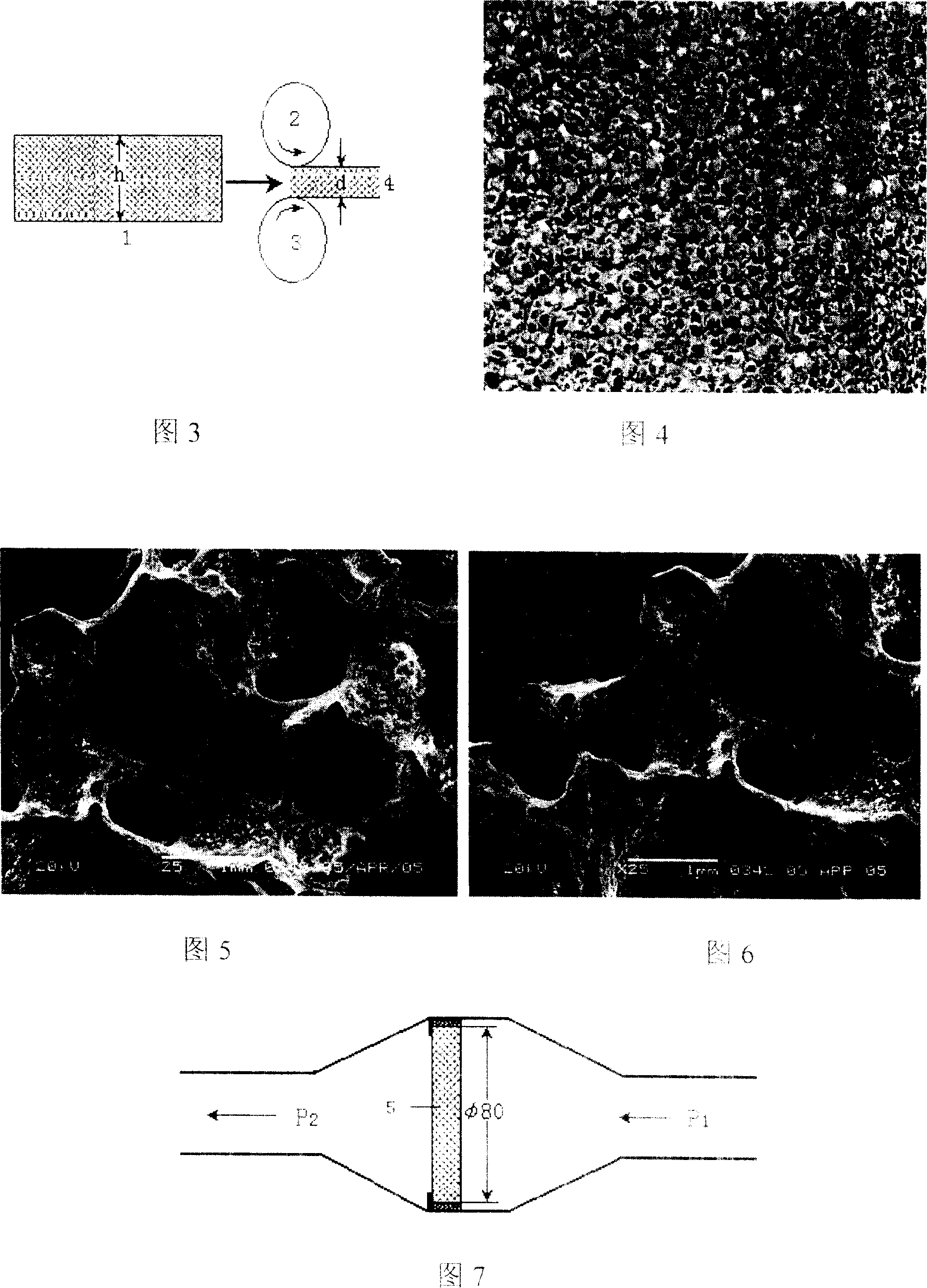

[0066] Preparation of TiAl / 316L Microporous Material

[0067] Prepared according to the process flow shown in Figure 2.

[0068] Select the raw materials in Table 4, use industrial alcohol as dispersant, polyvinyl alcohol as binder, mix in a cylinder mixer for 4 hours, then dry at 80°C, and cold isostatic press the mixed powder at 200Mpa into a green body. The obtained green body is first degreased in a vacuum furnace, and then raised to 1250°C according to a certain heating system for vacuum sintering (vacuum degree is 10 -2 pa), so that a porous material with silver-gray metallic luster can be obtained. The obtained porous material has an open porosity of 46.94%, and its closed porosity is less than 2.5%.

[0069] The material has almost no oxidation in the air at 800°C; it has been soaked in an acidic solution with a pH value of 2 for 24 hours, and no corrosion phenomenon has been found; it contains 2wt% SiO 2 After the aluminum melt was filtered through the microporous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com