Steam jet type heat pump heat distribution system for recovering thermal power plant condensing residual heat

A technology for heating systems and thermal power plants, applied in heating systems, hot water central heating systems, heating methods, etc., can solve problems such as waste, energy depreciation, and energy waste, and achieve simple equipment manufacturing, enhanced heat exchange effects, and full The effect of the heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

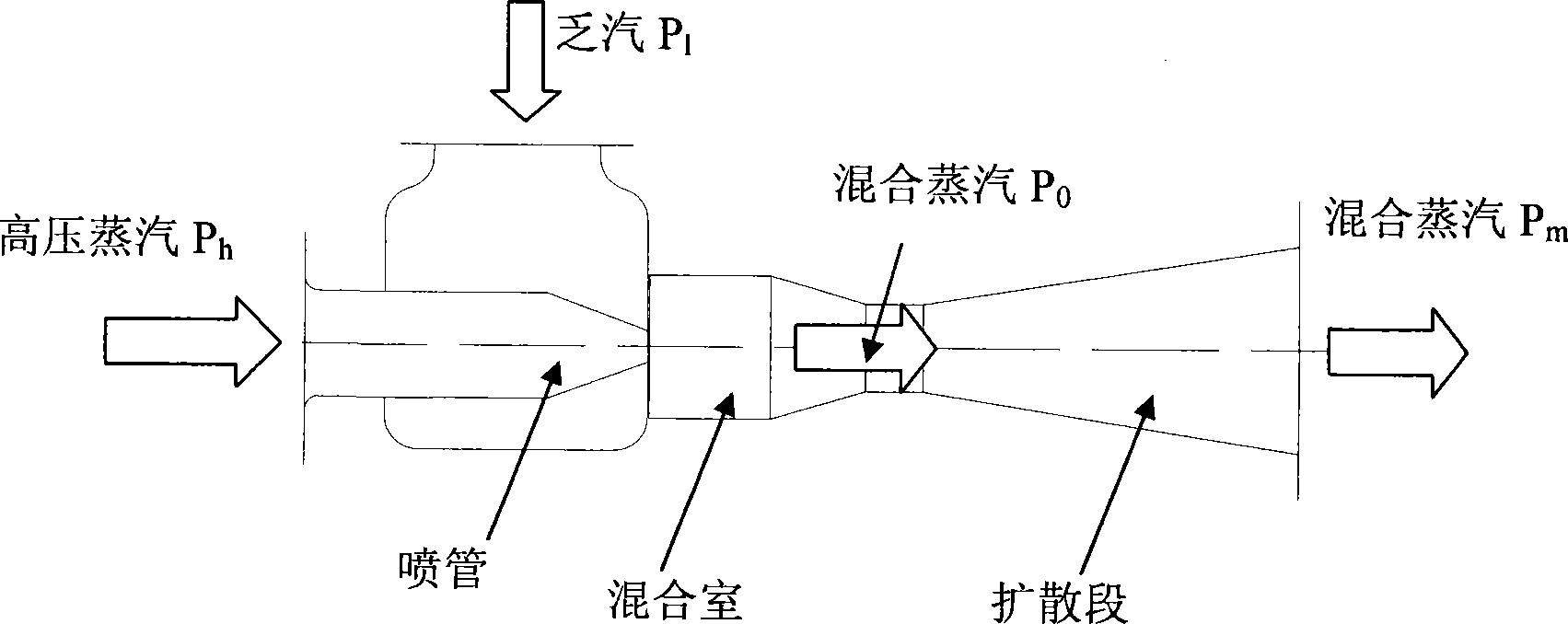

[0023] See attached figure 1 , figure 1 It is a schematic structural diagram of a typical single-stage steam ejector, based on the working principle of the ejector: working steam (pressure P h Higher pressure steam) accelerates through the nozzle in the injector to form a high-speed or even supersonic jet, while the ejected fluid (pressure P 1 The exhaust steam of the low-pressure steam turbine) is entrained by the high-speed jet into the mixing chamber, where the speed equalization and momentum (heat) transfer are carried out, and at the same time, accompanied by the increase of pressure, a single uniform mixed steam (pressure is P 0 medium pressure steam, P 1 0 k ). The mixed steam comes out of the mixing chamber and enters the diffusion section, and the pressure will continue to rise to P m (P 1 0 m k ). At the outlet of the diffuser section, the pressure P of the mixed steam m Higher than the pressure P of the ejected steam entering the mixing chamber 1 , so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com