Plastic modification device and method

A plastic and modified technology, applied in the field of plastic manufacturing, can solve the problems of inability to monitor, poor plastic fluidity, and insufficient melting of plastic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

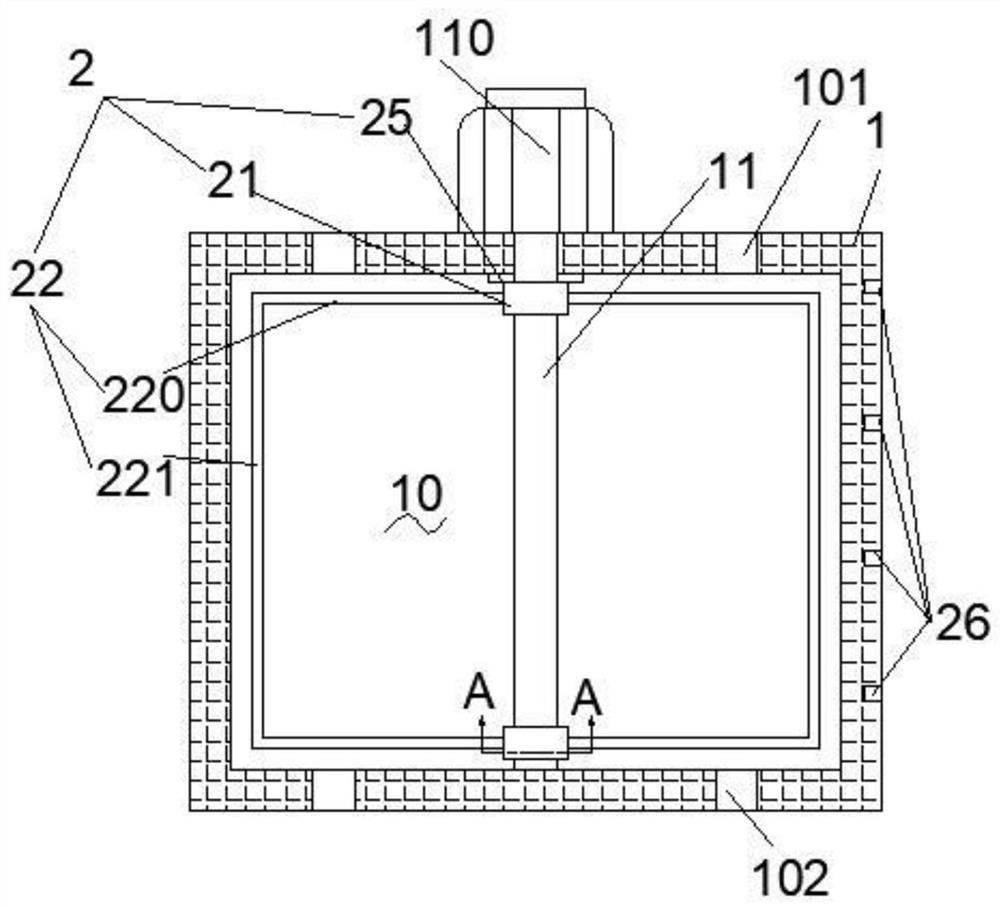

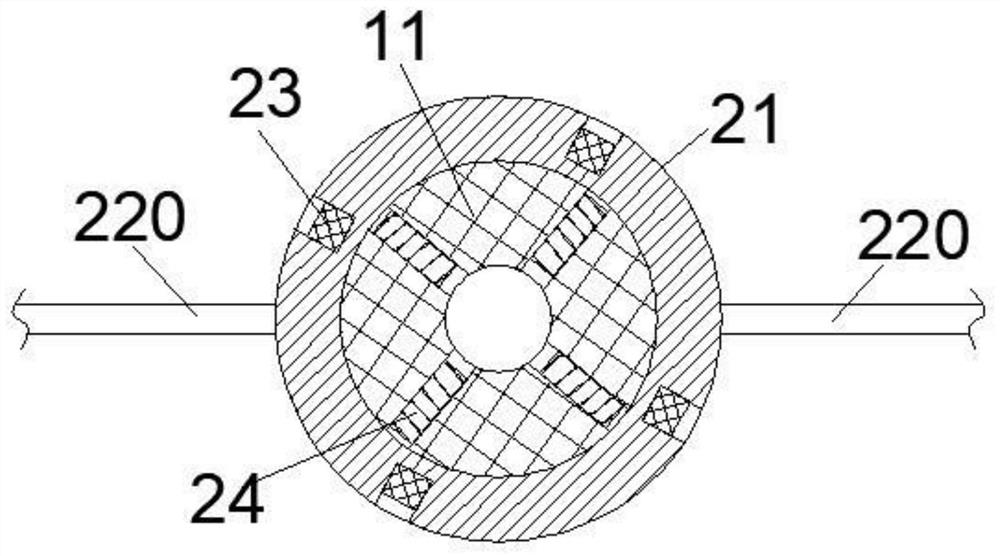

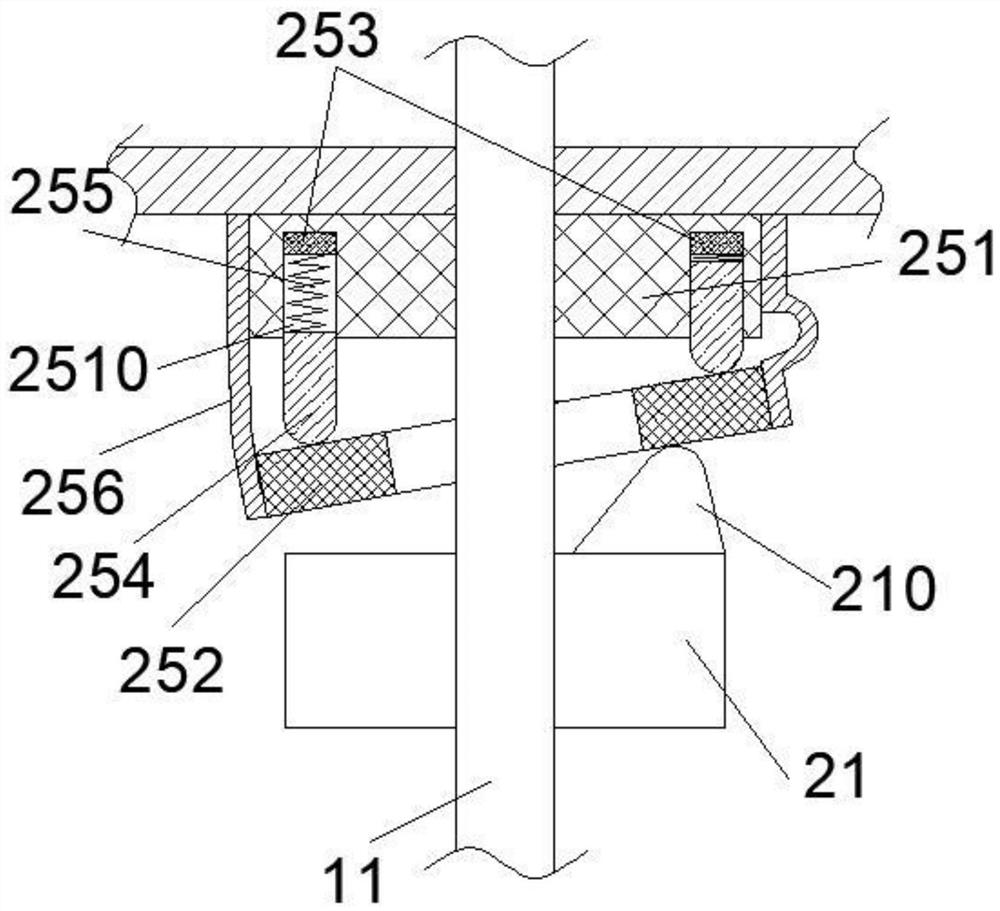

[0032] The invention provides a plastic modification device, referring to Figure 1-Figure 4 , as a specific embodiment, the device includes a stirring device 1, the stirring device 1 includes a stirring chamber 10 and a stirring shaft 11 rotatably arranged in the stirring chamber 10, the stirring shaft 11 is provided with a viscosity detection Device 2, the stirring chamber 10 is provided with a temperature detection device, the viscosity detection device 2 can detect the viscosity of the molten plastic in the stirring chamber 10 when the stirring shaft 11 is stirring; it also includes a control device 3, when the When the viscosity of the molten plastic in the stirring chamber 10 reaches a predetermined value, the control device 3 controls the stirring shaft 11 and the viscosity detection device 2 to stop working.

[0033] Specifically, refer to figure 1 , is a schematic structural diagram of the stirring device, the stirring device 1 includes a stirring chamber 10, and the...

Embodiment 2

[0048] Further, the present invention also provides a plastic modification method, refer to Figure 5 , the method includes:

[0049] S1. Using a plastic modification device provided in Example 1 to heat, melt and stir the plastic and modifier, and use the viscosity detection device 2 to detect the viscosity value of the molten plastic in the stirring chamber 10 and transmit it to The control device 3; thus, the viscosity value of the molten plastic in the stirring chamber can be detected by the viscosity detection device.

[0050] The control device 3 determines the mixing effect of the molten plastic and modifier in the current stirring chamber 10 according to the current temperature in the stirring chamber and the preset viscosity value model;

[0051] Specifically, the method for obtaining the viscosity model is as follows: wherein, the viscosity value model of the viscosity detection device 2 is based on the viscosity values of the detection samples at different meltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com