Solid salt heating and melting device and method

A technology of melting device and feeding device, used in melting, lighting and heating equipment, chemical instruments and methods, etc., can solve the problem of inconvenient large-scale processing of granular solid salt, easy corrosion of the inner wall, and inability to reliably and smoothly start the solid salt. Heating and other problems can prevent the volatilization and loss of molten salt, adjust reliably, and maintain the effect of current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

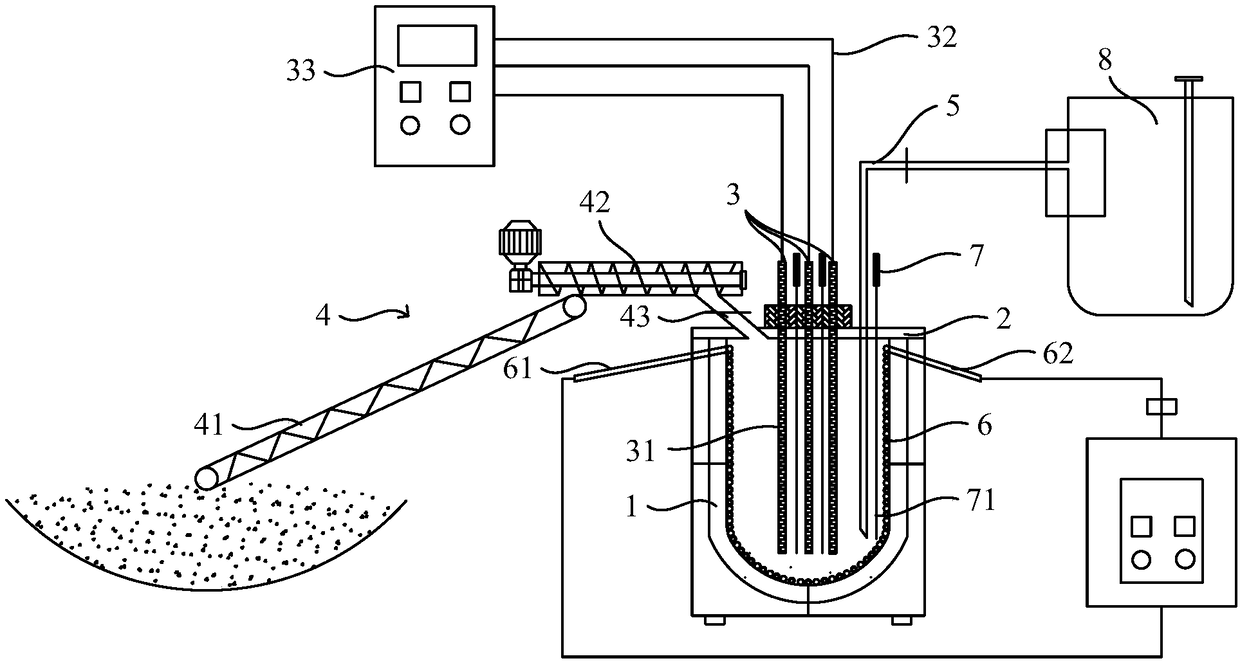

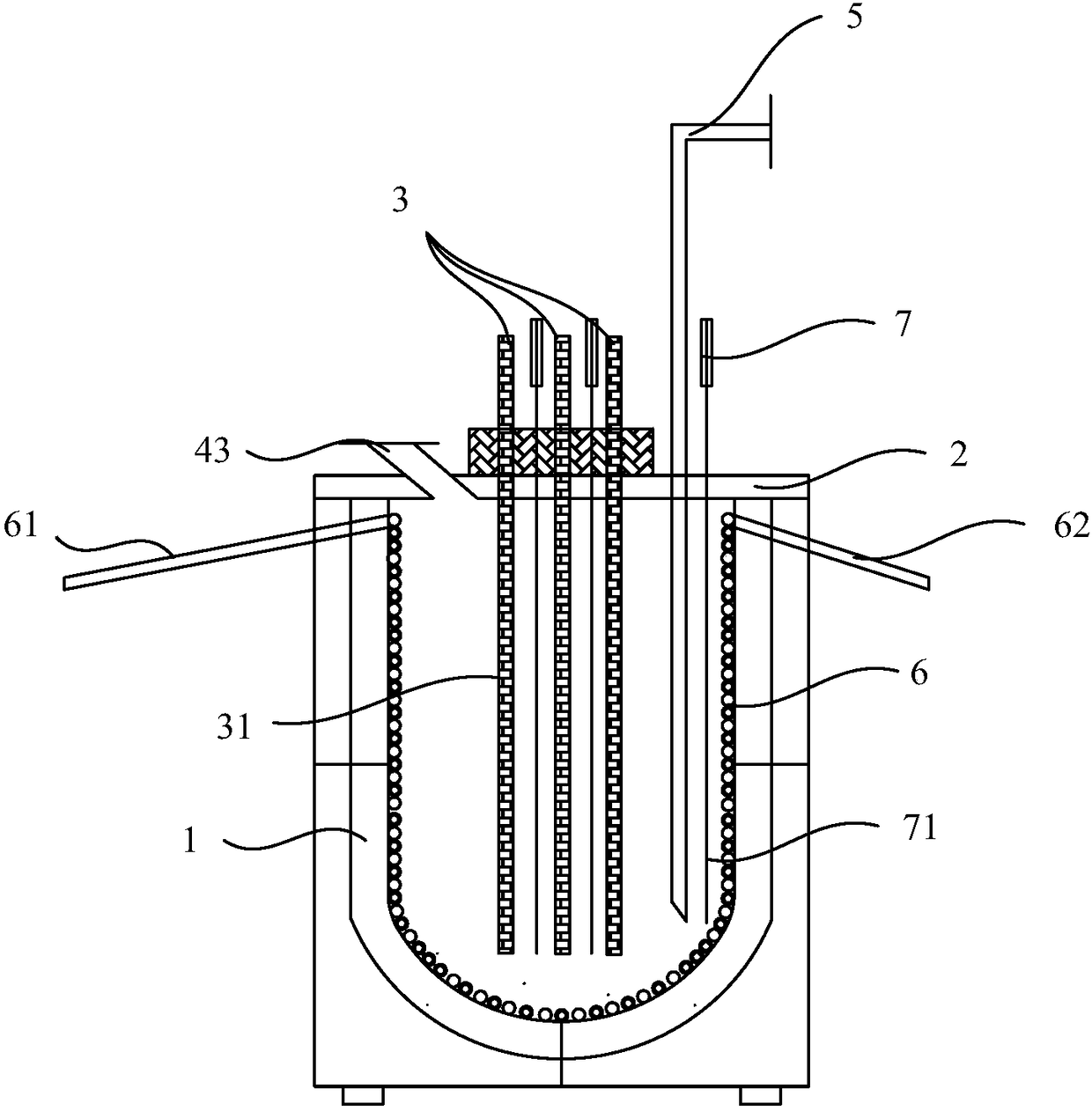

[0069] The solid salt heating and melting device of the present embodiment, such as figure 1 and figure 2 As shown, it includes a container body 1, a container cover 2 and an electrode group 3. The lower part of the container body 1 is closed and the upper part is open. The container cover 2 seals the upper part of the container body 1. The electrode group 3 is fixed on the container cover 2. The container body 1 It is arranged as a heat exchange jacket for cooling the inner wall of the container body 1 to form a frozen salt wall. The solid salt heating and melting device also includes a continuous feeding device 4 and a discharge pipe 5. The continuous feeding device 4 runs through the container cover 2, and the discharge pipe The material pipe 5 is fixed on the container cover 2, the electrode group 3 and the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com