Method and device for producing silicon monoxide

A technology of silicon oxide and silicon dioxide, applied in the direction of silicon oxide, the method of chemically changing substances by using atmospheric pressure, chemical instruments and methods, etc., can solve the problems of complex production process and low efficiency of silicon oxide, and achieve The effect of short process, full utilization and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0210] Embodiment 1 silicon mud raw material preparation and determination silicon content

[0211] Silica mud material is gray-black, mainly contains silicon powder, and contains liquid ranging from 10-30%. Put 5kg of the silica mud into a quartz crucible and dry it in an oven at 110°C for 24 hours until no volatile odorous gas overflows to obtain a large piece of silica mud, then crush the block of silica mud and bake it repeatedly to 230°C until Silica mud was below 100 mesh without weight loss, and 3943 grams of dry silica mud was obtained. All subsequent experiments used silica mud prepared by this method as raw materials.

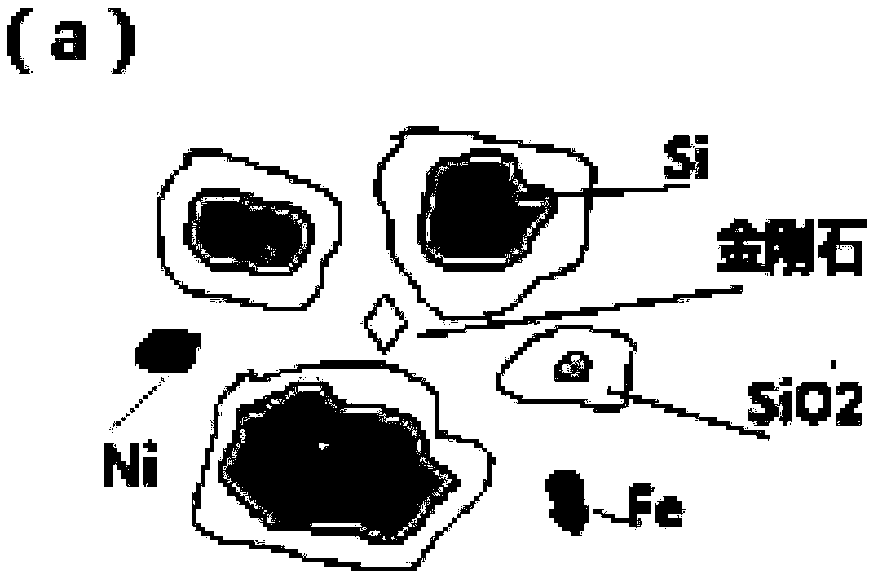

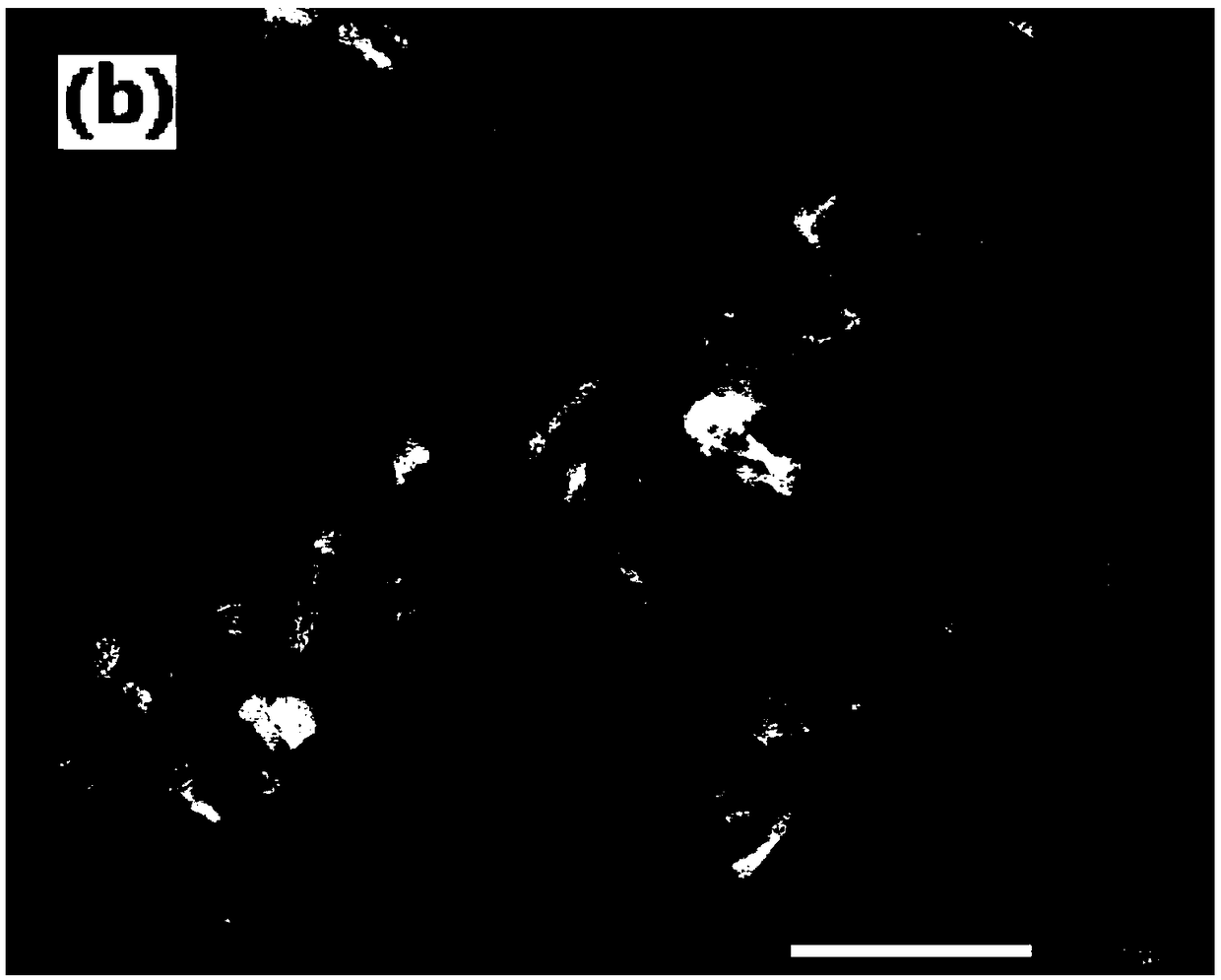

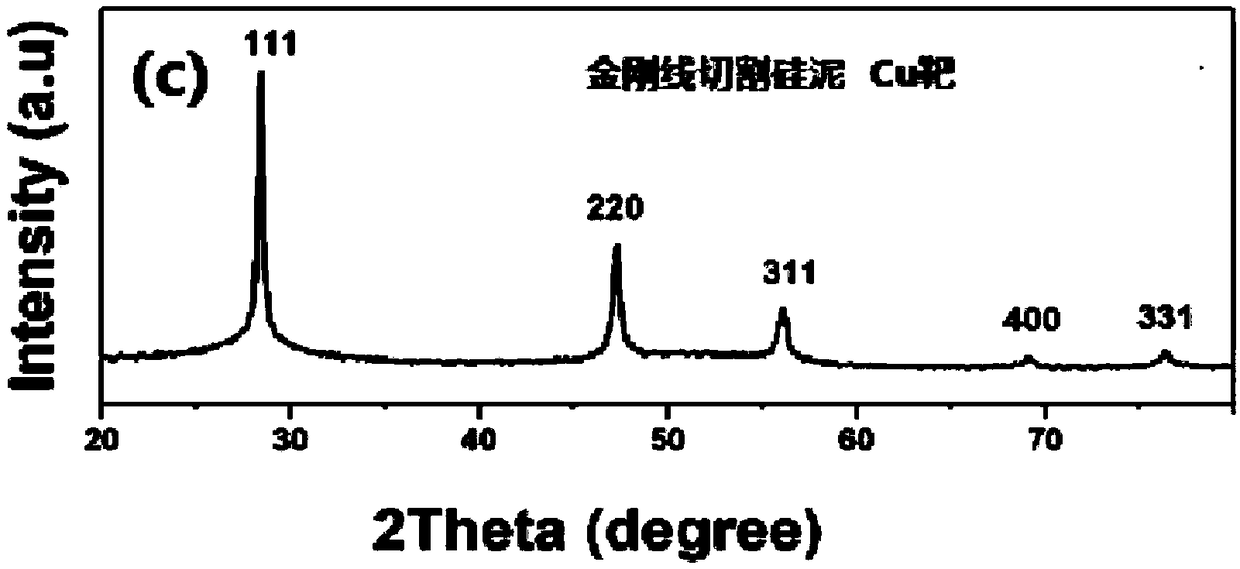

[0212] Figure 1b and Figure 1c It is the scanning electron micrograph ( Figure 1b ) and X-ray diffraction pattern ( Figure 1c ). It can be seen that there are no other crystalline materials except silicon, but the silicon oxide on the surface of silicon particles is amorphous and has no diffraction peaks.

[0213] First, the content of sili...

Embodiment 2

[0216] Get 2000 grams of dry silicon mud material that embodiment 1 obtains, put into 2000ml graphite crucible, put into vacuum induction melting furnace (Shanghai Chenhua), first vacuumize to 10 -3 Vacuum below tor, then flush with high-purity argon and heat to 1500°C. During the heating process, silicon oxide is generated and volatilized. After the melting of silicon is observed through the transparent window, until no silicon oxide volatilizes, 1400 grams of crystalline silicon (including the inseparable part left in the crucible) after natural cooling, some If it remains in the crucible and cannot be taken out, the weight of the crucible increases by 30 grams, and its appearance and structure are similar to polysilicon. In addition, this experiment did not connect a special device for collecting silicon oxide, and at the same time, some silicon oxide was not completely reacted, only 5 grams of powder samples were obtained from the inner wall of the vacuum melting furnace r...

Embodiment 3

[0218] Such as image 3 As shown, a 500KW industrial melting furnace is used, with a built-in graphite crucible of 200 liters and a graphite top cover on the top. A stainless steel barrel with a diameter of 120 cm and a height of 2 meters is connected externally through a 12-foot quartz tube, and then a Roots fan is connected to draw air to ensure that the inside of the stainless steel barrel For continuous negative pressure (0.7-0.9atm), the outside is cooled with tap water.

[0219] Add 25 kg of dry silicon powder to the graphite crucible for the first time (due to the low density of silicon powder, it depends on the particle size distribution, generally 0.6-1.2g / cc, which is much lower than the density of elemental silicon 2.3 and the density of molten silicon is greater than Elemental silicon, up to 2.56) Start the induction heating element 2 and heat the crucible to 1500-1600°C within 2 hours, wait until there is no overflow of silicon oxide, stop heating, and repeat 5 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com