Melting atomization system, high-activity spherical cuprous chloride catalyst prepared through system and preparation method of high-activity spherical cuprous chloride catalyst

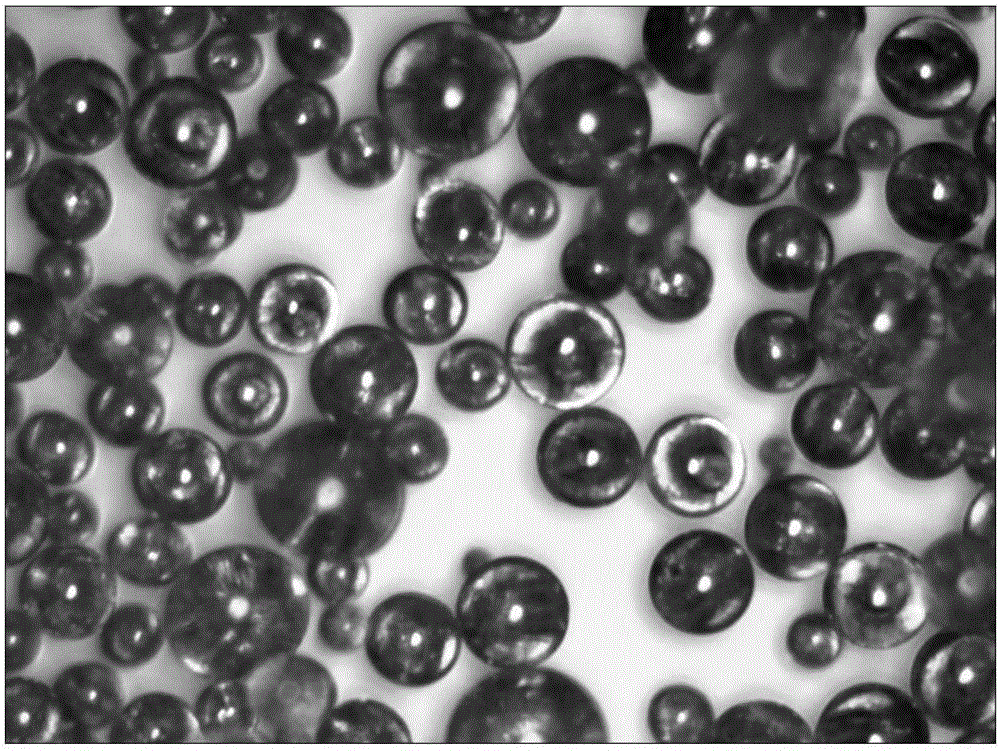

An atomization system, cuprous chloride technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of large powder particle size dispersion coefficient, excessive energy consumption, low yield and other problems , to achieve the effect of concentrated product particle size, reduced energy consumption and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

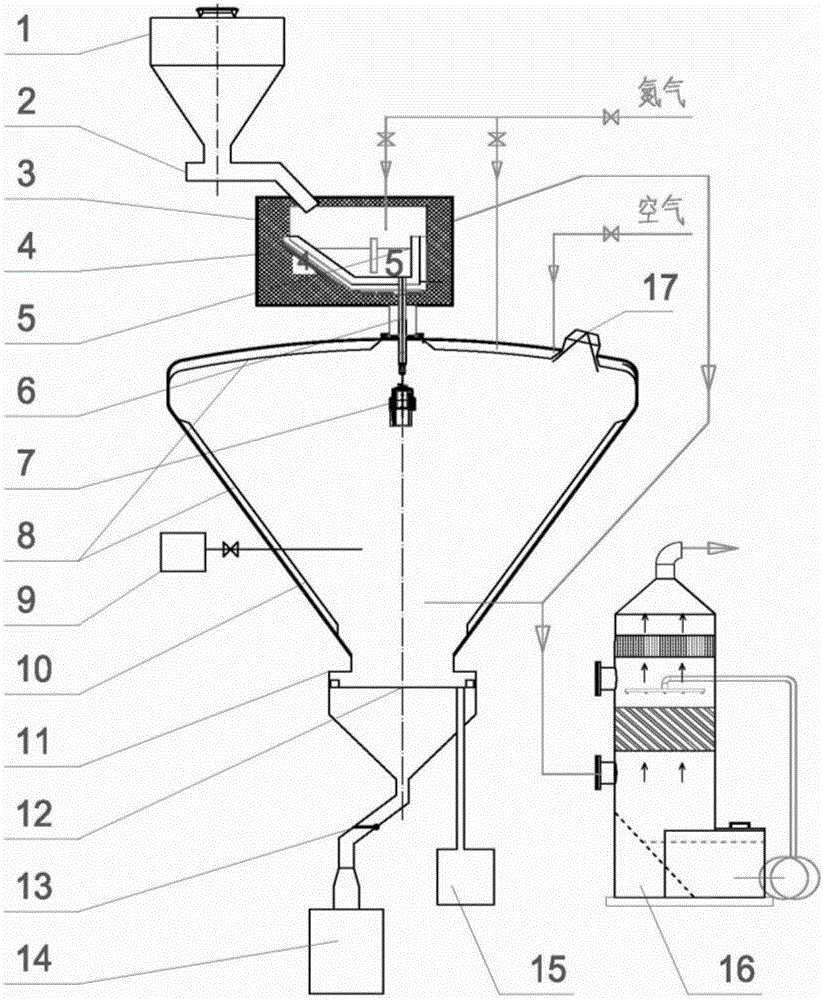

[0052] A melt atomization system such as figure 1 As shown, it includes a storage tank 1, a conveying feeder 2, a melting furnace 3, an atomizing tank 10 and a screening mechanism 11 connected in sequence, and a rapid melting device 4 and an atomizing tundish furnace 5 are arranged in the melting furnace. The atomizing tank 10 is equipped with an atomizing disc 7, and the atomizing tundish furnace is connected to the atomizing disc 7 through a guide tube 6. The screening mechanism has a built-in screen 12, and the bottom of the screening mechanism is connected to the finished product packaging machine 14 through a pipeline. , This section of the pipeline is provided with a powder discharge valve 13, and the collection pipeline and the coarse powder collection tank 15 pass through the screen above. The atomization tank is equipped with a cooling mechanism 8, which is a double-layer structure provided on the inner wall of the atomization tank to contain a cooling medium.

[00...

Embodiment 2

[0057] A preparation method of highly active spherical cuprous chloride powder, the specific steps are as follows:

[0058] (1) Put the cuprous chloride powder raw material into the storage tank 1, use the conveying feeder 2 to transport the raw material to the melting furnace 3, and the rapid melting device 4 in the melting furnace melts the raw material rapidly, and the raw material is melted by atomization The tundish furnace 5 is kept warm at 435-650°C to prepare for atomization. The melting of the melting furnace and the transportation of raw material powder are carried out under the protection of inert gas to avoid oxidation reaction of raw materials during melting. The melting capacity of the melting furnace can be determined according to the required atomization capacity.

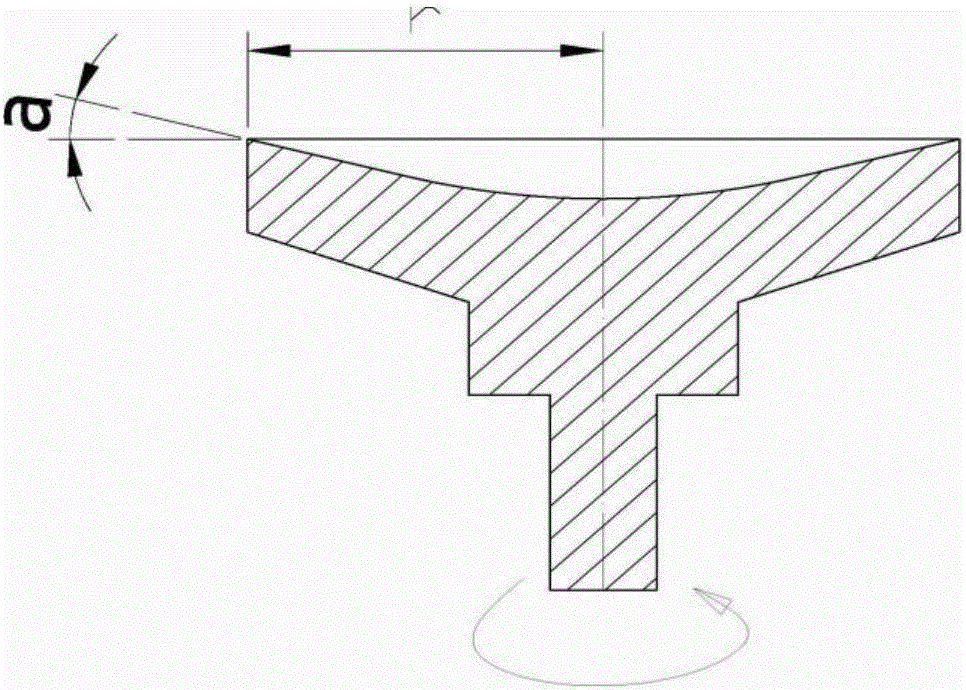

[0059] (2) The molten cuprous chloride liquid is introduced into the atomizing disc 7 in the atomizing tank 9 through the heated draft tube 6 . The atomizing disc is driven by a high-speed motor. ...

Embodiment 3

[0066] Adopt the system described in embodiment 1 to carry out the preparation of highly active spherical cuprous chloride powder, concrete process is: first use respectively 2-4m 3 / h and 50m 3 Nitrogen per hour replaces the melting furnace 3 and the atomizing tank 10, and replaces the oxygen concentration in the container to below 500ppm, and then reduces the flow rate of the protective gas to 1m 3 / h and 15m 3 / h. The filled raw materials are hoisted to the material storage barrel 1, and then the melting furnace 3 is started to heat up. When the furnace temperature reaches 550°C, the conveying feeder 2 starts feeding. When the liquid level of the atomizing tundish furnace 5 reaches 2 / 3 and the temperature reaches 500°C, the draft tube 6 starts to heat. When the temperature of the draft tube is higher than At 430°C, the liquid cuprous chloride begins to fall and atomize, and the atomization flow rate is 120KG / h. The motor speed of the atomizing disc 7 is 20,000 rpm, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com