Melting device for curing agent coating producion

A melting device and curing agent technology, applied in the direction of melting, chemical instruments and methods, chemical/physical processes, etc., can solve the problems that cannot meet the production needs of the factory, easily adhere to the inside of the melting device, and inconvenient cleaning work, etc., to avoid The effect of causing harm to the body, good filtering effect, and convenient unloading work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

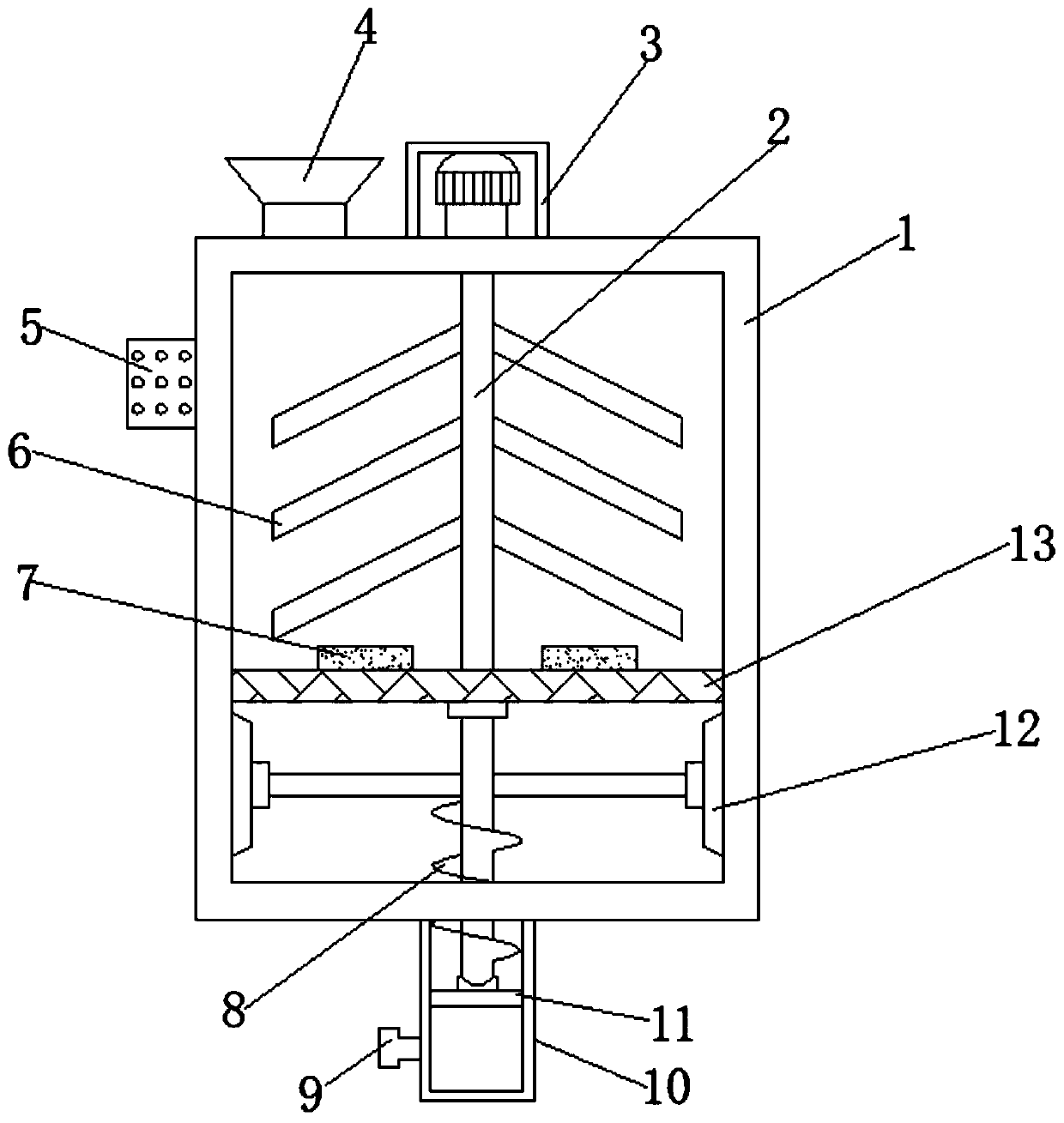

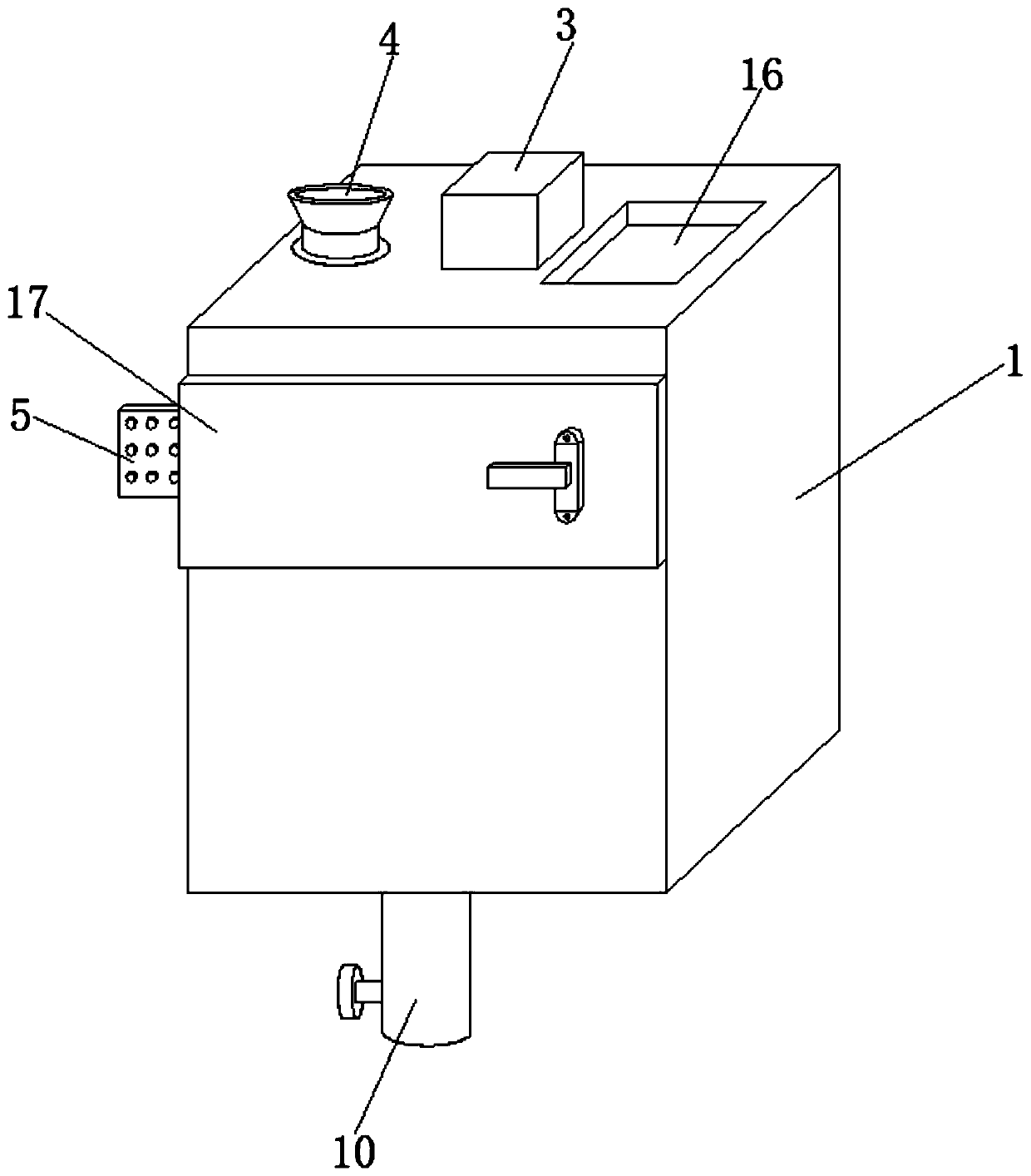

[0025] refer to Figure 1-2 , a melting device for curing agent coating production, comprising a box body 1, the inner walls of both sides of the box body 1 are connected with filter screens 13 by bolts, and the top outer wall of the filter screen 13 is provided with a heating block 7, the top of the box body 1 There is a fixing hole on the outer wall, and a feed hopper 4 is welded in the fixing hole. The top outer wall of the box body 1 is connected with a protective shell 3 by bolts, and the top inner wall of the protective shell 3 is connected with a motor by bolts. The outer wall of the output shaft of the motor is The rotating column 2 is welded, and the outer walls on both sides of the rotating column 2 are connected with stirring rods 6 by bolts.

[0026] Wherein, the bottom inner wall of the box body 1 is plugged with a feeding pipe 10, and the outer walls of both sides of the feeding pipe 10 are welded with fixing rods 11, and the outer wall of one side of the feeding...

Embodiment 2

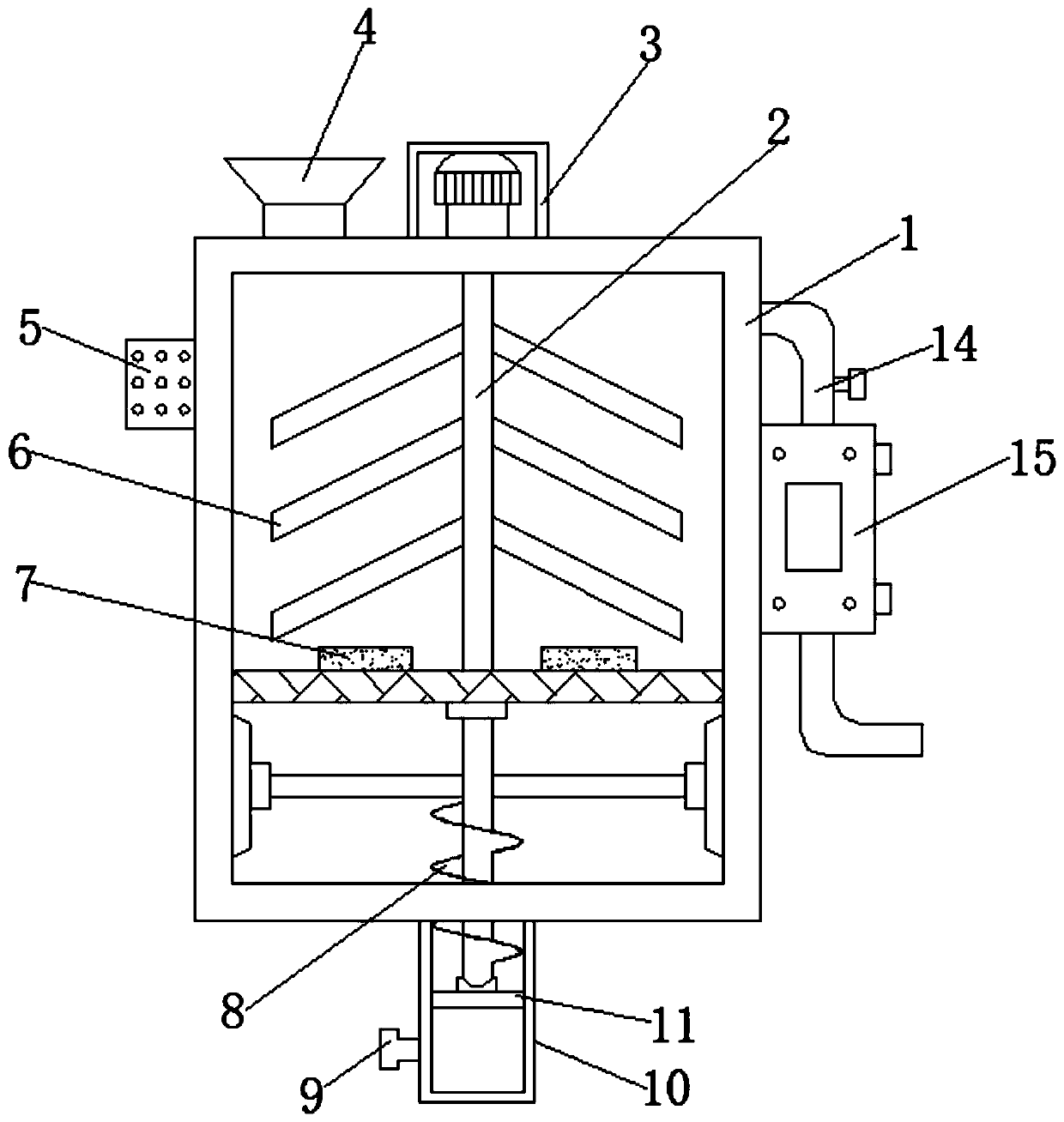

[0029] refer to image 3 , a melting device for curing agent paint production. Compared with Embodiment 1, the outer wall of one side of the box body 1 is connected with an air guide pipe 14, and one end of the air guide pipe 14 is connected with an air cleaner 15. The purifier 15 is connected to one side outer wall of the box body 1 by bolts.

[0030] Working principle: When in use, the staff puts the material into the box 1 through the feed hopper 4, melts the material through the heating block 7, and starts the motor at the same time, and the motor drives the rotating column 2 and the stirring rod 6 to rotate together to process the material. Stirring work improves the rate of material melting. When the device is performing melting work, open the control valve on the outer wall of the air guide pipe 14, and the waste gas generated during the melting process enters the air purifier 15 through the air guide pipe 14 to purify the waste gas. Avoid the direct discharge of exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com