Industrial HW11 and HW08 hazardous waste treatment method

A technology for hazardous waste and disposal methods, which is applied in the petroleum industry, chemical instruments and methods, and the preparation of liquid hydrocarbon mixtures, etc. It can solve the problems of inability to achieve harmless disposal of hazardous waste, high processing costs, and waste heat that cannot be recovered. , to achieve the effect of strengthening the supervision of the whole process, protecting the environment and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

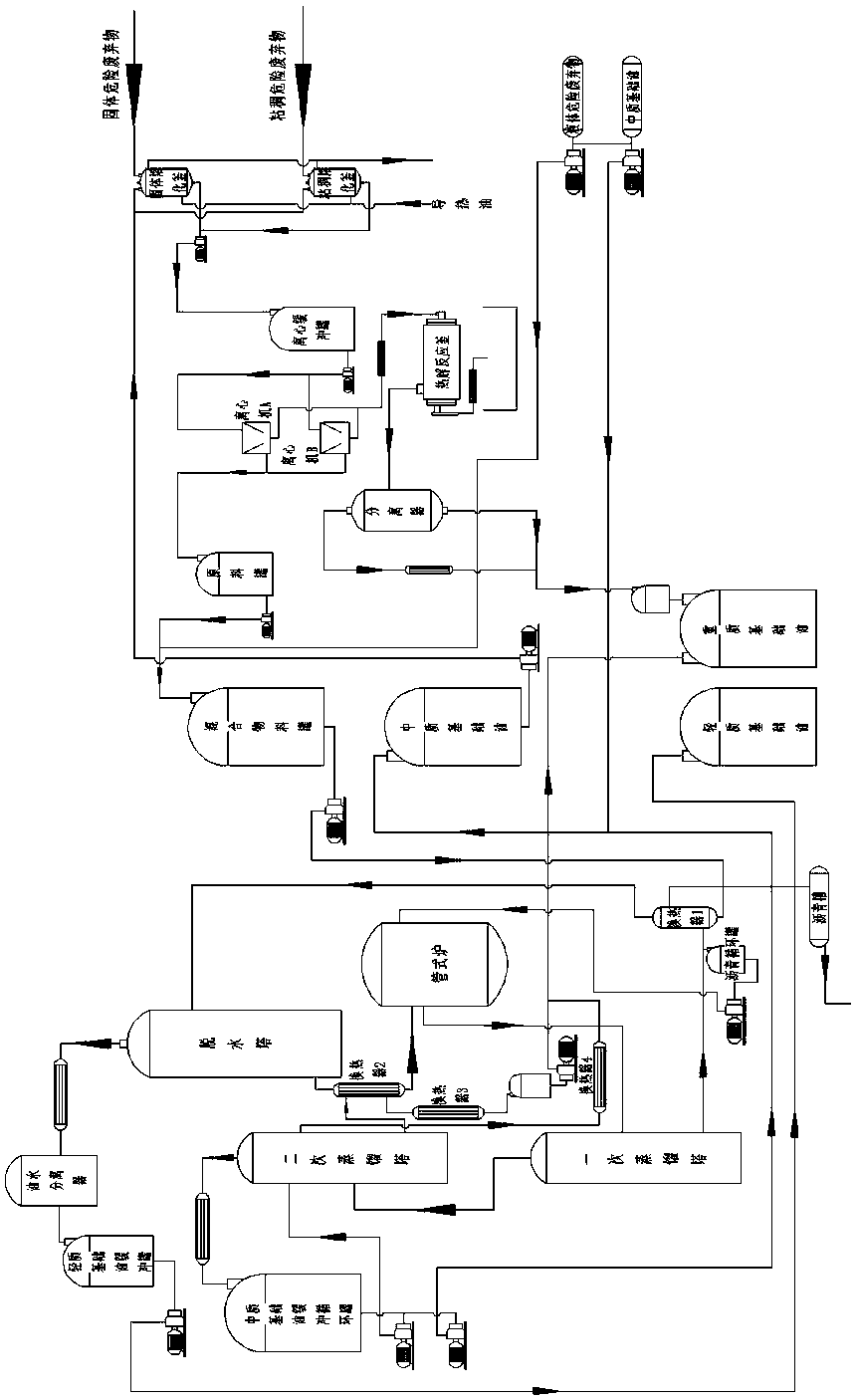

Image

Examples

Embodiment 1

[0027] A method for disposing of industrial hazardous waste HW11 and HW08 hazardous waste, which classifies HW11 and HW08 hazardous waste into solid hazardous waste, viscous hazardous waste and liquid hazardous waste. The solid hazardous waste The disposal steps are as follows: crush the solid hazardous waste and send it to the solid melting tank, add the extractant to the solid melting tank, heat it to 200°C through heat conduction oil, stir for 10 minutes, and discharge it to centrifuge A after being buffered by the centrifugal buffer tank , separating the solid waste extract into solid hazardous waste filtrate and solid hazardous waste filter residue, the solid hazardous waste filtrate enters the mixture tank through the raw material tank, and the solid hazardous waste filter residue enters the pyrolysis reactor.

[0028] The disposal steps of the viscous hazardous waste are as follows: put the viscous hazardous waste into the viscous melting tank, add the extractant into th...

Embodiment 2

[0037] A method for disposing of industrial hazardous waste HW11 and HW08 hazardous waste, which classifies HW11 and HW08 hazardous waste into solid hazardous waste, viscous hazardous waste and liquid hazardous waste. The solid hazardous waste The disposal steps are as follows: crush the solid hazardous waste and send it to the solid melting tank, add the extractant to the solid melting tank, heat it to 180°C through heat conduction oil, stir for 18 minutes, and discharge it to centrifuge A after being buffered by the centrifugal buffer tank , separating the solid waste extract into solid hazardous waste filtrate and solid hazardous waste filter residue, the solid hazardous waste filtrate enters the mixture tank through the raw material tank, and the solid hazardous waste filter residue enters the pyrolysis reactor.

[0038]The disposal steps of the viscous hazardous waste are as follows: put the viscous hazardous waste into the viscous melting tank, add the extractant to the v...

Embodiment 3

[0047] A method for disposing of industrial hazardous waste HW11 and HW08 hazardous waste, which classifies HW11 and HW08 hazardous waste into solid hazardous waste, viscous hazardous waste and liquid hazardous waste. The solid hazardous waste The disposal steps are as follows: crush the solid hazardous waste and send it to the solid melting tank, add the extractant to the solid melting tank, heat it to 150°C through heat conduction oil, stir for 30 minutes, and discharge it to centrifuge A after being buffered by the centrifugal buffer tank , separating the solid waste extract into solid hazardous waste filtrate and solid hazardous waste filter residue, the solid hazardous waste filtrate enters the mixture tank through the raw material tank, and the solid hazardous waste filter residue enters the pyrolysis reactor.

[0048] The disposal steps of the viscous hazardous waste are as follows: put the viscous hazardous waste into the viscous melting tank, add the extractant to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com