Asphalt concrete plant-mix hot recycling equipment with improved structure

A technology for asphalt concrete and structural improvement, applied in the direction of roads, road repair, roads, etc., can solve the problems of asphalt mixture bonding and other problems, and achieve the effect of reducing the failure rate and avoiding the problem of sticking materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

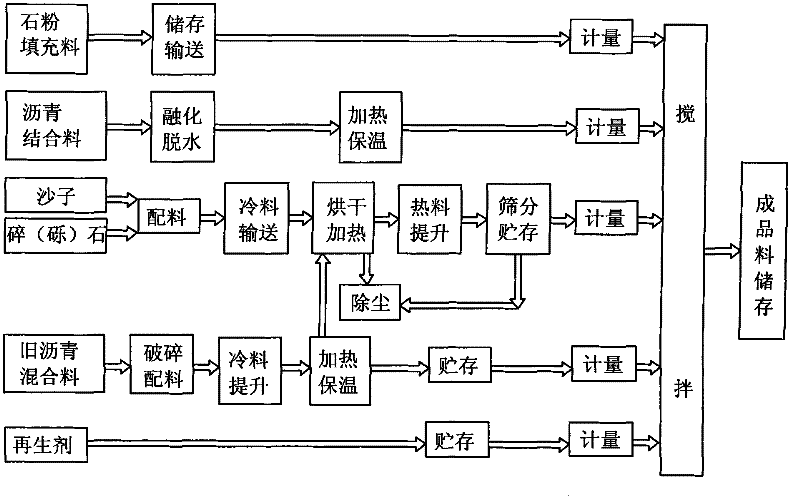

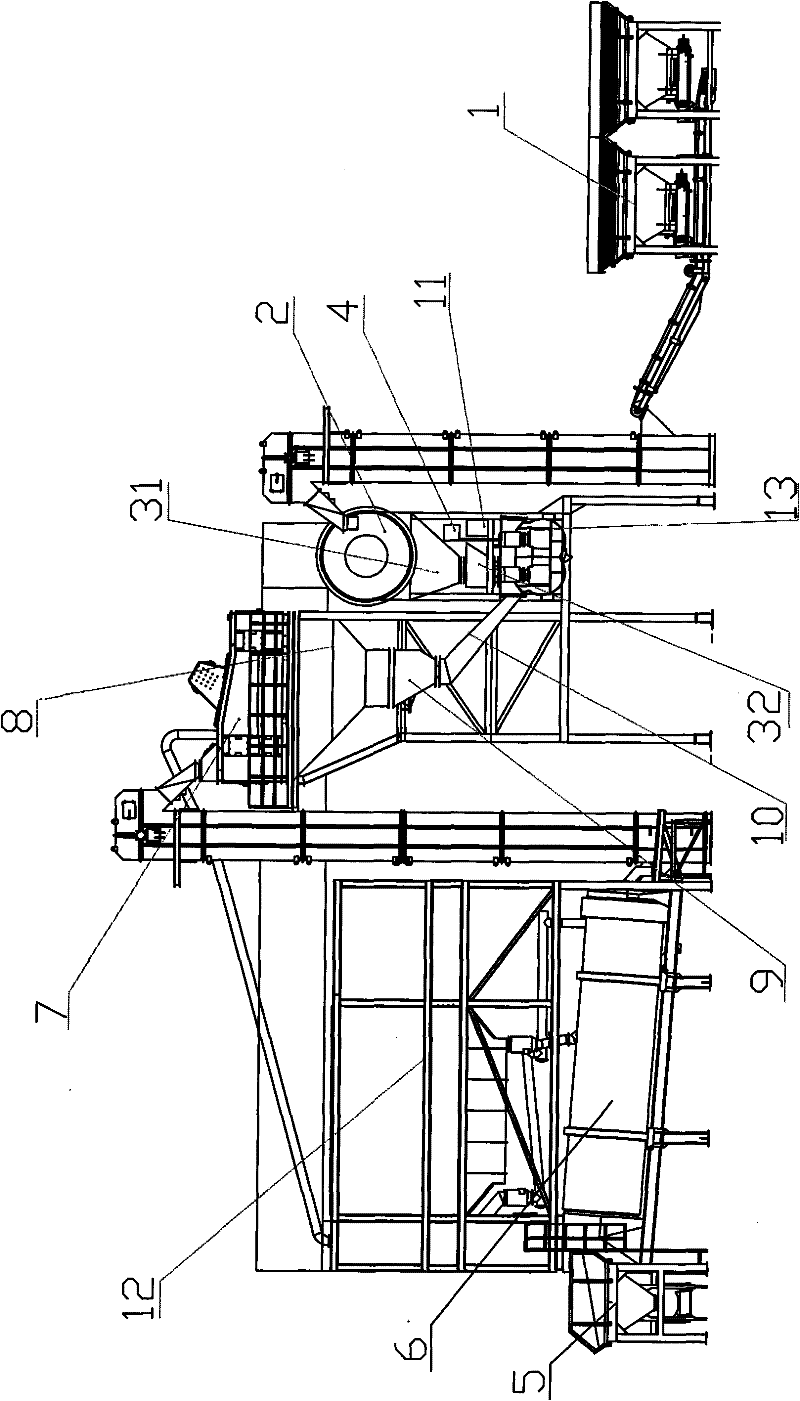

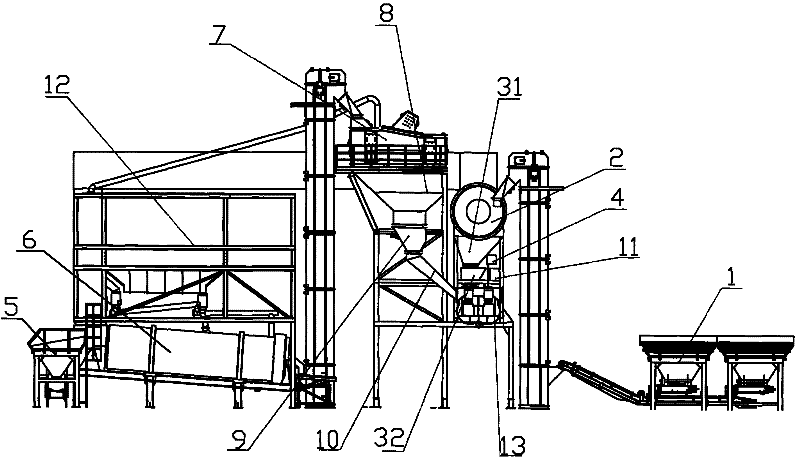

[0015] Such as figure 2 As shown, the structurally improved asphalt concrete plant mixing heat regeneration equipment provided by the present invention includes the following parts:

[0016] The old asphalt mixture processing system, including the old asphalt mixture batching conveying device 1, which is used to transport the old asphalt mixture with primary control gradation to the thermal regeneration drying drum 2; the thermal regeneration drying drum 2 is used for drying and heating The old asphalt mixture forms the old asphalt thermally recycled material; the old asphalt thermally recycled material storage metering device is installed above the stirring device 13, including a storage bin 31 for receiving and storing the old asphalt thermally recycled material, and a storage bin for receiving and sending out The metering hopper 32 is used to measure hot recycled asphalt. The discharge port of the metering hopper 32 is directly connected to the feed port of the mixing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com