Asphalt regeneration roller and method for preventing materials from being stuck on roller inner wall

A kind of asphalt recycling drum and drum technology, which is applied in the field of asphalt recycling drum and the inner wall of the asphalt recycling drum, which can solve the problems of difficult maintenance, high cost, low thermal efficiency, and sticking of drying drums, so as to reduce production and maintenance costs, clean High efficiency and stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

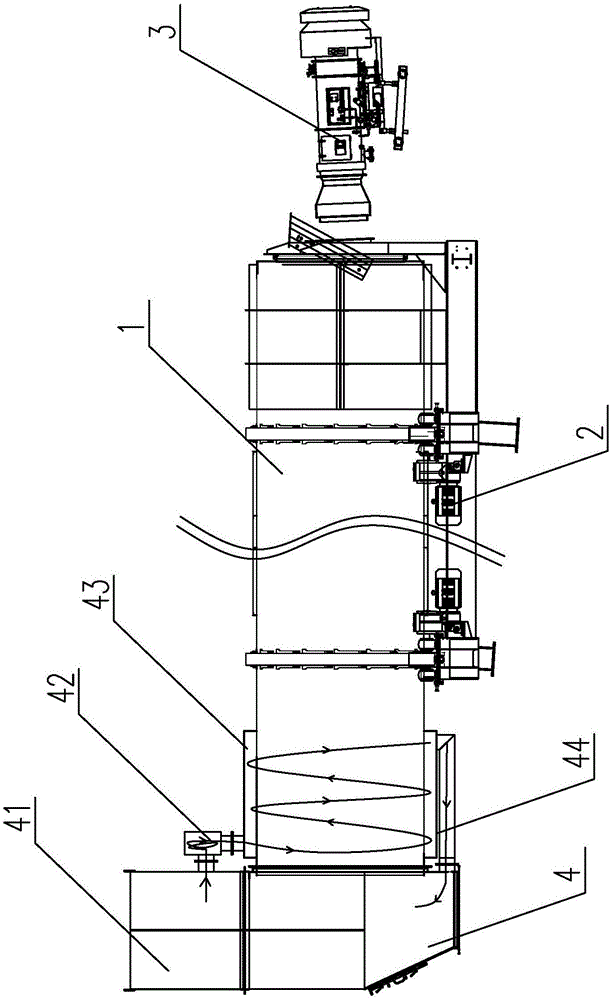

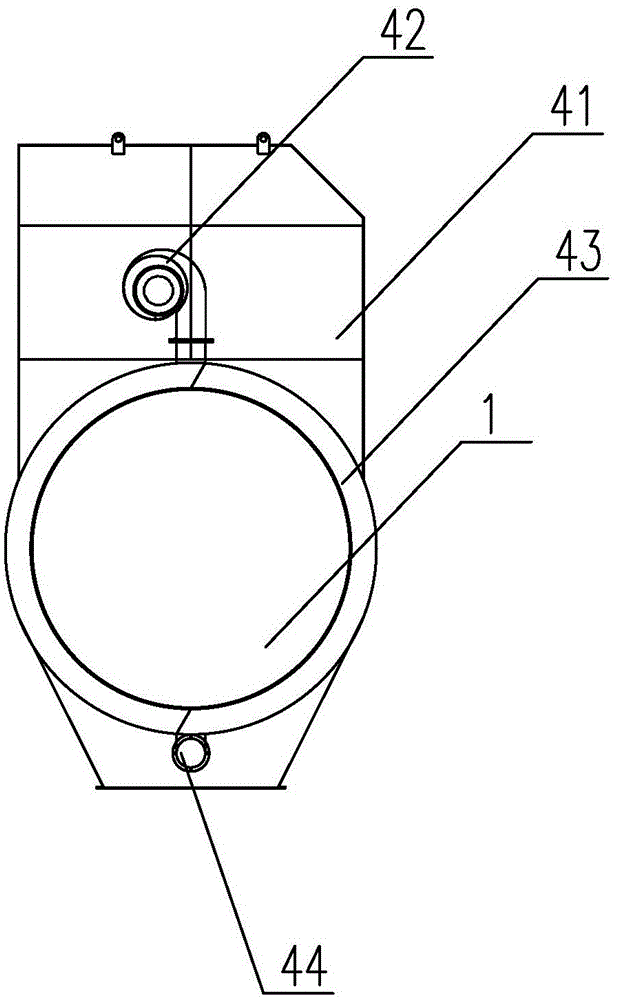

[0024] refer to Figure 1 to Figure 3 As shown, the cylinder wall heating device 4 includes an air collection box 41, an air induction device 42, a heating pipe 43, an air outlet pipe 44 and an external heat source. The air collection box 41 is arranged at the tail end of the drum body 1 to collect the For the exhausted flue gas, the air induction device 43 communicates with the gas collecting box 41 to introduce the high-temperature flue gas in the gas collecting box into the heating pipe 43, and the heating pipe 43 is attached to the wall of the drum body 1 to support the drum body 1. The wall is heated, the air outlet pipe 44 communicates with the heating pipe 43 and the gas collecting box 41 to form a circulating air path, and the external heat source provides high-temperature air into the heating pipe.

[0025] When the above-mentioned asphalt regeneration drum is working, the recycled asphalt material enters the drum body 1 from the feed port at the front end of the drum...

specific Embodiment 2

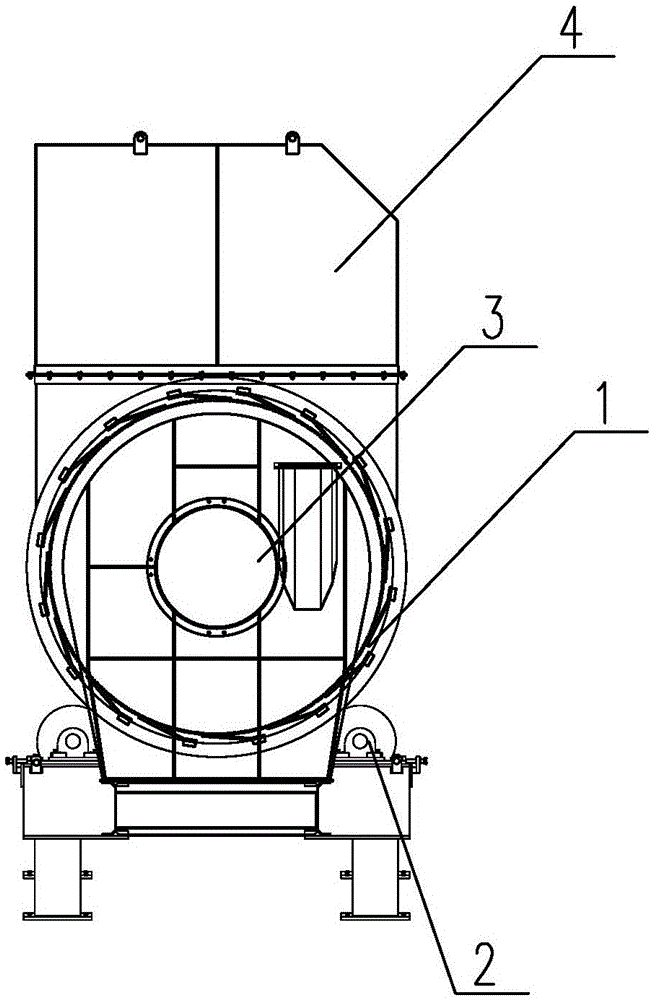

[0027] refer to Figure 4 , Figure 5 As shown, the cylinder wall heating device includes a gas collecting box 41a, a heating burner 42a and a heating pipe 43a, and the gas collecting box 41a is arranged at the tail end of the drum body 1 to collect the smoke discharged from the drum body 1 and the heating pipe 42a, The heating burner 42a provides high-temperature flue gas into the heating pipe 43a, and the heating pipe 43a is attached to the wall of the drum body 1 to heat the wall of the drum body 1, and the flue gas in the heating pipe 43a is discharged through the gas collecting box 41a.

[0028] When the above-mentioned asphalt regeneration drum is working, the recycled asphalt material enters the drum body 1 from the feed port at the front end of the drum body 1, and the recycled asphalt moves to the tail end of the drum body 1 with the rotation of the drum body 1, and at the same time, the drying material burner 3 pairs of regeneration The asphalt material is dried and...

specific Embodiment 3

[0030] refer to Figure 6 As shown, the drum body 1 includes an inner drum 11 and an outer drum 12, a heating channel 13 is formed between the inner drum 11 and the outer drum 12, and the drum wall heating device is connected to the heating channel 12 and heats it, and the drum wall heating device 4 It is heat conduction oil heating device, hot air heating device, burner heating device, electric heating device or other heating methods.

[0031] When the asphalt regeneration drum mentioned above is working, the recycled asphalt material enters the inner drum, and when the drum body 1 rotates, the inner drum 11 rotates relative to the outer drum 12, and the drum wall heating device 4 heats the drum wall of the inner drum 11 to asphalt through the heating channel. The temperature at which the raw material melts into a liquid makes the recycled material bonded on the inner wall of the cylinder have considerable fluidity.

[0032] refer to Figure 1 to Figure 6 As shown, the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com