Cross flow siphon toilet bowl

A toilet and siphon technology, which is applied in the field of cross-flow siphon toilets, can solve the problems of incomplete flushing such as contamination and accumulation of dirt on the surface of the toilet pot, manually scrubbing the surface of the pot body, and low flushing force, etc., to achieve a solution The problem of sticky dirt, strong flushing force, and the effect of reducing water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

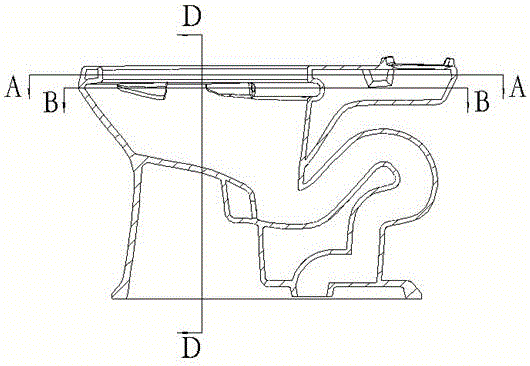

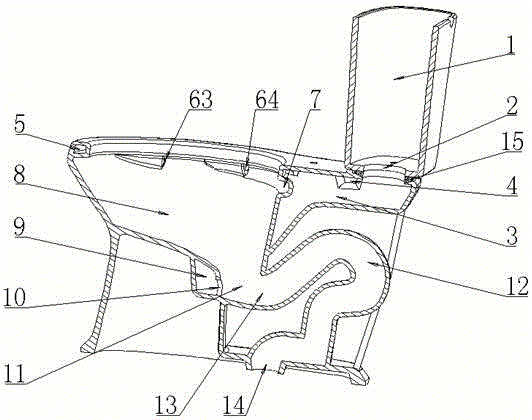

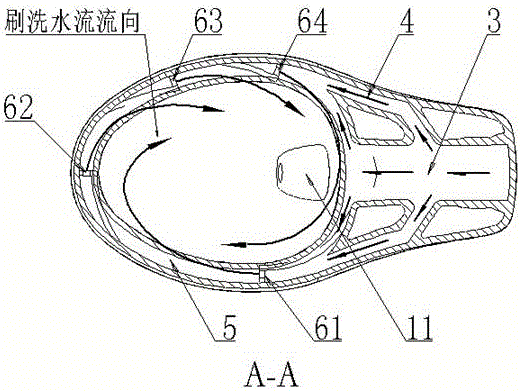

[0028] Such as figure 1 , figure 2 As shown, the cross-flow siphon toilet includes a toilet body, the toilet body includes a pot body 8, and the mouth of the pot body 8 has a circle 5, and a water tank 1 is arranged on the rear and upper part of the toilet body, and an inlet is provided in the middle of the bottom of the water tank 1. The water hole 2, the toilet body and the water tank are connected by a sealing rubber ring 15, the main water channel 3 is arranged at the rear and upper part of the toilet body, and the auxiliary water channel 9 for spraying water is provided in the front and lower direction of the main water channel 3, and the two sides of the main water channel 3 A diversion waterway 4 is provided, the main waterway 3 and the diversion waterway 4 communicate with the circle 5 respectively, and the circle 5 is provided with a plurality of cross flow nozzles; the bottom of the pot body 8 is provided with a hat head 11, and the end of the auxiliary waterway 9 e...

Embodiment 2

[0038]As shown in Fig. 8 and Fig. 9, there is no guide groove under the track 5, and the number of cross-flow nozzles under the track 5 is increased from 4 to 6, and the 6 cross-flow nozzles are evenly distributed under the track 5. The cross-flow nozzle includes six nozzles, the end surface of the cross-flow nozzle is perpendicular to the horizontal direction or forms an angle less than or equal to 45 degrees with the vertical surface, and the opening angle is perpendicular to the end surface; the six nozzles are respectively the first nozzle 610, the second Nozzle 620, the third nozzle 630, the fourth nozzle 640, the fifth nozzle 650 and the sixth nozzle 660; the six nozzles are arranged on the ring road 5 in turn, and the third nozzle 630 is arranged on the front end of the ring road 5, The sixth nozzle 660 is arranged at the rear end of the circle 5; the water flow sprayed by the cross-flow nozzle forms a clockwise flushing water flow in the pot body 8 when viewed from abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com