Lithium battery wire exposed wire end insulation production process

A production process and technology of lithium batteries, applied in circuits, electrical components, circuit/collector parts, etc., can solve problems such as insufficient tightness, moisture and oxidation of exposed wire ends, affecting welding processes, etc., and achieve good moisture resistance. Oxidation effect, the effect of solving the difficulty of tightness control, and the effect of solving the problem of moisture oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

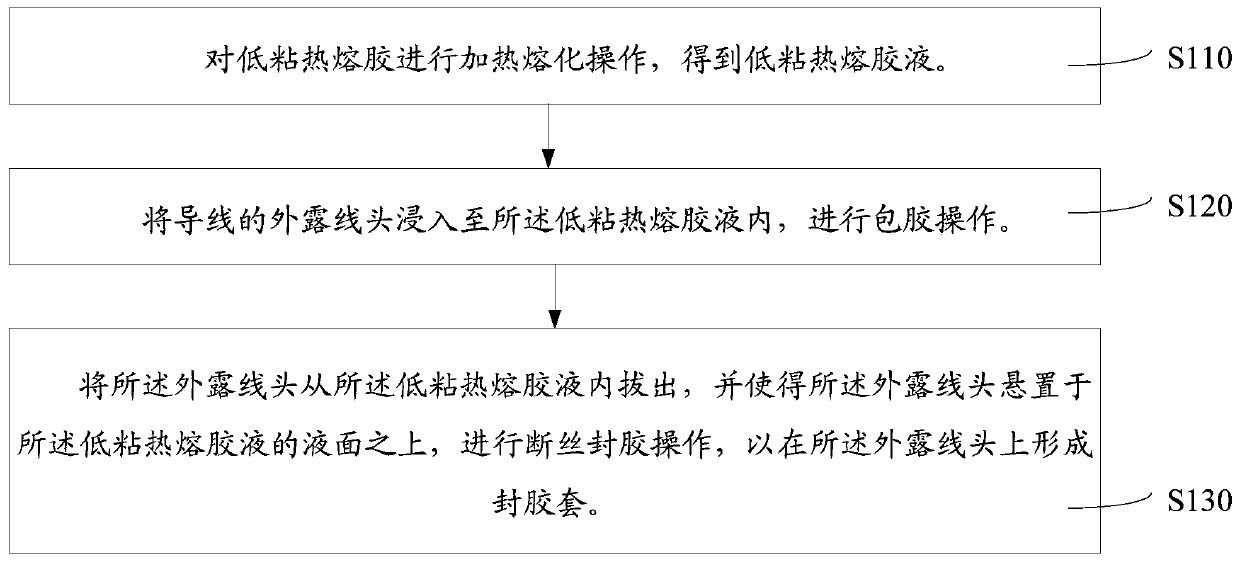

[0034] In order to better describe the above-mentioned production process for the exposed wire end insulation of lithium battery wires, to better understand the concept of the above-mentioned production process for the exposed wire end insulation of lithium battery wires. For an implementation, see figure 1 , a lithium battery lead wire exposed end insulation production process, comprising the following steps: S110, performing a heating and melting operation on the low-viscosity hot-melt adhesive to obtain a low-viscosity hot-melt adhesive liquid. S120, immersing the exposed wire ends of the wires into the low-viscosity hot-melt glue liquid, and performing the encapsulation operation. S130, pulling out the exposed thread ends from the low-viscosity hot-melt adhesive liquid, and suspending the exposed thread ends above the liquid surface of the low-viscosity hot-melt adhesive liquid, and performing a broken wire sealing operation, to form a sealing sleeve on the exposed wire e...

Embodiment 1

[0063] S111, at a temperature of 160°C, stir 10 parts of polyurethane resin, 40 parts of polysulfide rubber, 3 parts of antioxidant 1010, 1 part of diphenylguanidine, 2 parts of zinc peroxide, 60 parts of methanol and 10 parts of paraffin Operation, so that the components are mixed uniformly to obtain a low-viscosity hot-melt adhesive, and the low-viscosity hot-melt adhesive is heated and melted so that the temperature of the low-viscosity hot-melt adhesive reaches 160°C to obtain a low-viscosity hot-melt adhesive.

[0064] S121, immersing the exposed wire ends of the wires into the low-viscosity hot-melt adhesive liquid for 1 second, and performing the encapsulation operation.

[0065] S131, pull out the exposed thread end from the low-viscosity hot-melt adhesive liquid, and make the exposed thread end suspend at a distance of 3 mm above the liquid surface of the low-viscosity hot-melt adhesive liquid to stay for 1 second, and carry out Sealing of broken wires to form a seali...

Embodiment 2

[0067] S112, under the temperature condition of 220 ℃, for 20 parts of polyurethane resin, 20 parts of polysulfide rubber, 10 parts of antioxidant TNP, 0.5 parts of tetramethylthiuram monosulfide, 4 parts of lead dioxide, 40 parts of toluene and Stir 20 parts of paraffin to mix the components evenly to obtain low-viscosity hot-melt adhesive. Heat and melt the low-viscosity hot-melt adhesive so that the temperature of the low-viscosity hot-melt adhesive reaches 220°C to obtain low-viscosity hot-melt adhesive. Melt glue.

[0068] S122, immersing the exposed end of the wire into the low-viscosity hot-melt glue liquid for 2 seconds, and performing a glue-covering operation.

[0069] S132, pull out the exposed thread end from the low-viscosity hot-melt adhesive liquid, and make the exposed thread end suspend at a distance of 2 mm above the liquid surface of the low-viscosity hot-melt adhesive liquid for 2 seconds, and perform Sealing of broken wires to form a sealing sleeve on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com