High-efficient sticking-blocking resistant wear-resistant round roller screen

An anti-sticking, high-efficiency technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increased difficulty in dust recycling, impact on air permeability, easy sticking, etc., to achieve full utilization of the screening area, screening Improved capacity and stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

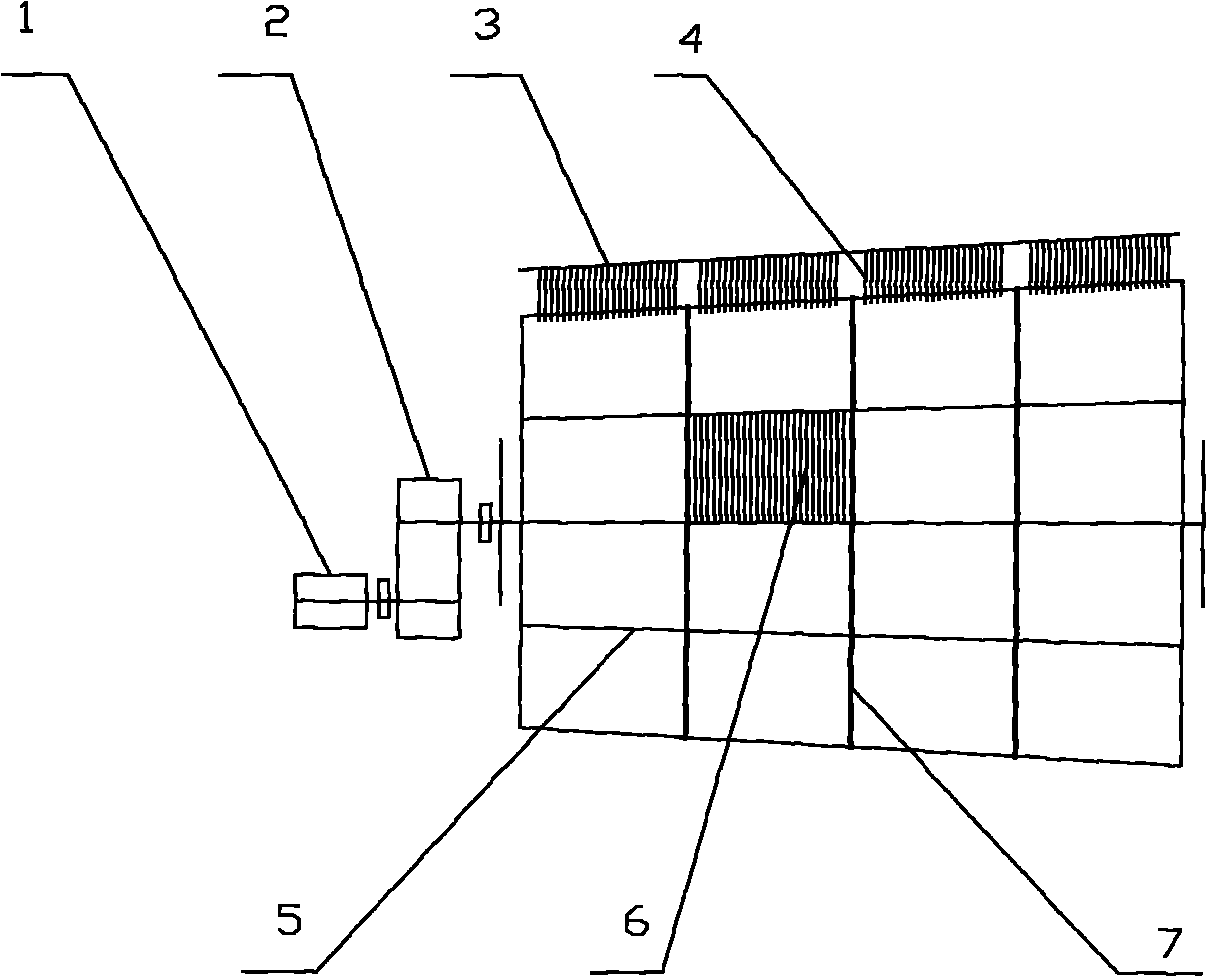

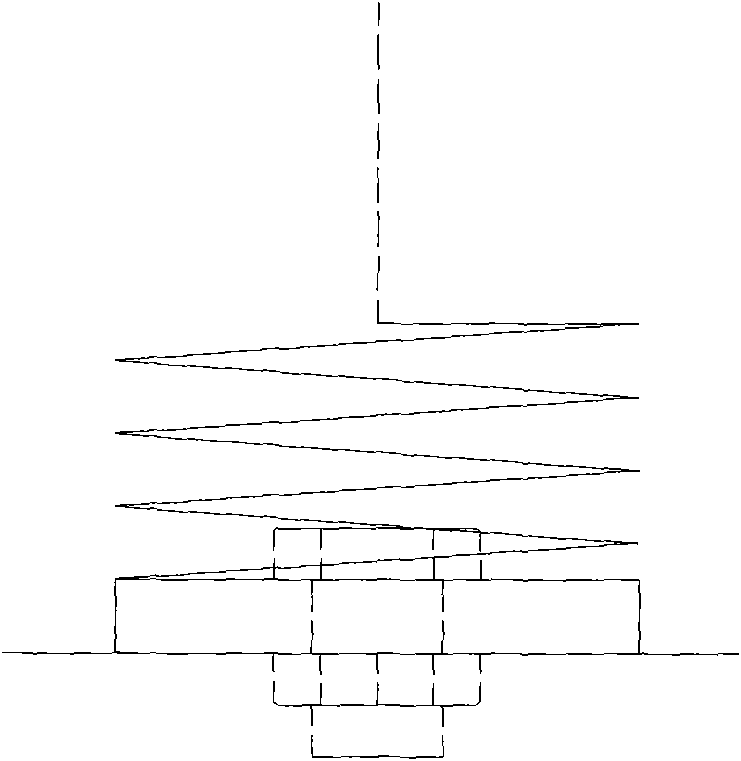

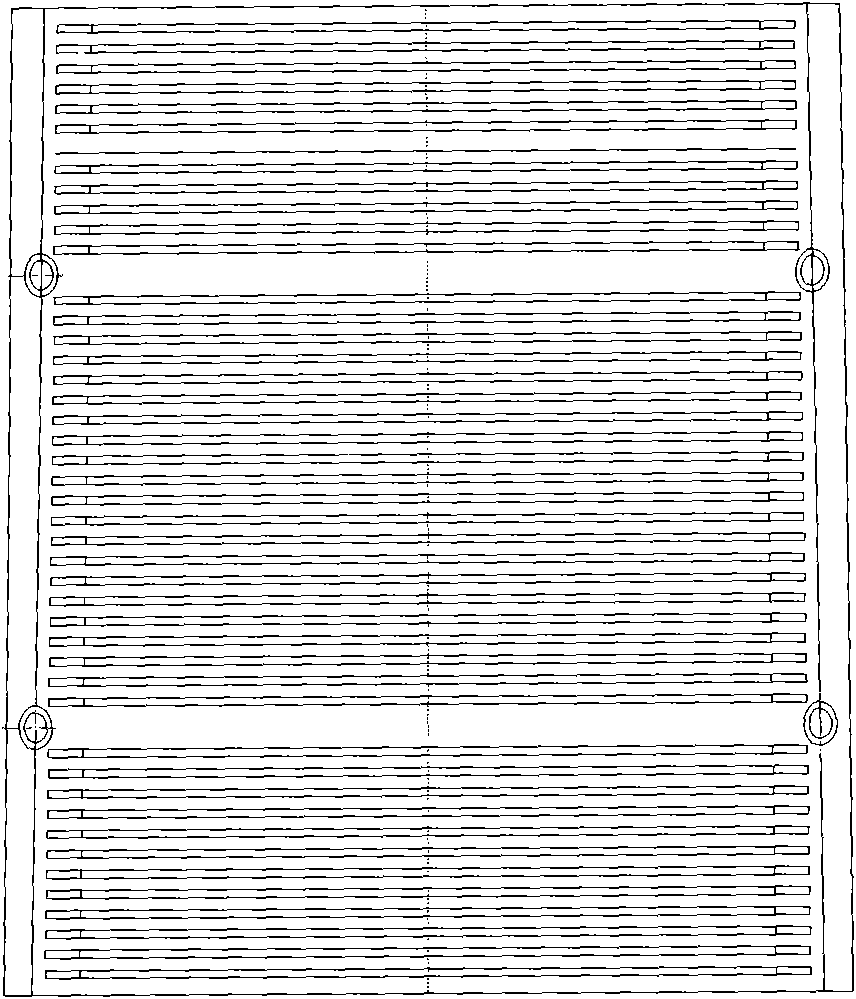

[0010] The equipment structure of the present invention is mainly composed of sieve frame, sieve plate (6), elastic brush (4), brush plate (3), reducer (2), motor (1) and other components (see the accompanying drawings figure 1 ). figure 1 For the principle structure diagram, figure 2 is a schematic diagram of an elastic brush, image 3 A schematic diagram of the sieve plate, Figure 4 Schematic diagram of a sieve tooth. Among them, the screen frame is composed of a plurality of rolling rings (7) and beams (5). Its shape is in the shape of a cylinder or a round table. The filling rate, screening time, production capacity and other parameters are calculated and determined; the sieve plate (see image 3 ) is arc-shaped, cast from wear-resistant steel, and is composed of multiple sets of sieve teeth (see Figure 4 ) are combined in parallel, the shape of the screen teeth is close to "V", and it is composed of two arcs of radius R and two parallel line segments. "V" shape, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com