Asphalt regenerating roller with anti-adhesion heating device and anti-adhesion method

A technology of asphalt regeneration drum and heating device, which is applied in roads, road repairs, roads, etc. It can solve the problems of dry drum sticking, difficult maintenance, high cost, and low thermal efficiency, so as to reduce bonding performance, reduce overall energy consumption, The effect of solving the sticky problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific embodiments.

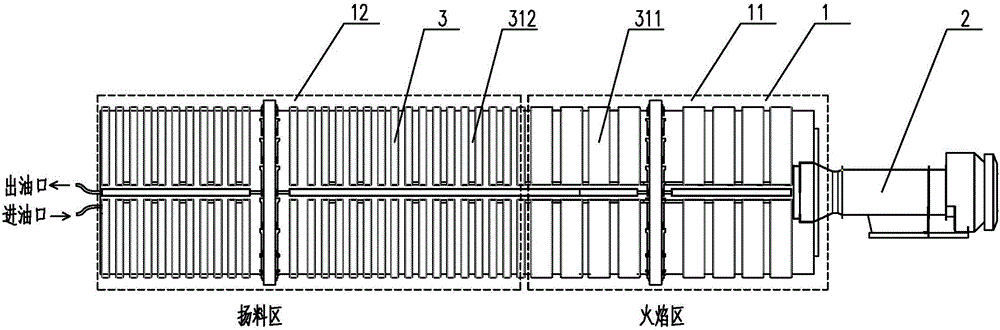

[0023] refer to Figure 1 to Figure 2 As shown, the asphalt regeneration drum with the anti-adhesive material heating device includes a drum body 1, a burner 2, an anti-adhesive material heating device 3 and insulation cotton.

[0024] The drum body 1 includes an outer drum and an inner drum, and the inner drum is divided into a combustion zone 11 and a lifting zone 12 in sequence.

[0025] The burner 2 is connected to the front end of the combustion zone of the drum body 1 for heating the regenerated asphalt in the drum body 1 .

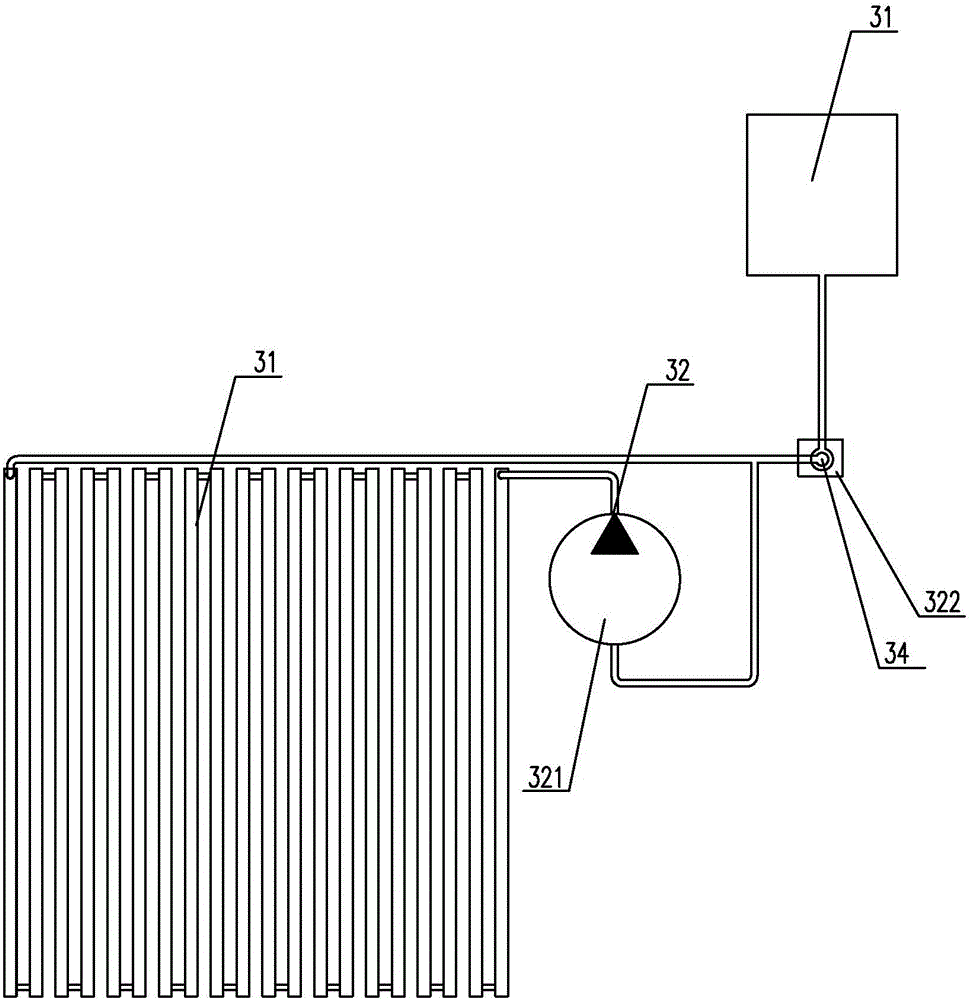

[0026] The anti-stick material heating device 3 includes a heat transfer oil pipeline 31, a heat transfer oil delivery device 32, a heat transfer oil tank 33 and a hydraulic rotary structure 34;

[0027] The heat transfer oil pipeline 31 includes a heat transfer oil heating pipeline 311 arranged on the outer wall of the drum body combustion zone 121, a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com