Environmentally-friendly hot-melt pressure sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive, environmentally friendly technology, used in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of affecting the adhesion performance of hot-melt pressure-sensitive adhesives and weakening system compatibility and other problems, to achieve the effect of increasing the layer spacing, reducing the amount of gel, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of described environment-friendly type hot-melt adhesive, comprises the steps:

[0060] Step 1. Mix the thermoplastic elastomer and plasticizer evenly, and let stand for 2 hours;

[0061] Step 2. Heat the above mixture until it melts, add modified petroleum resin, natural tackifying resin and coupling agent, control the temperature at 160-180°C, and stir at a constant speed of 300r / min for 30-40min;

[0062] Step 3: Add antioxidant, continue to stir for 10-12 minutes, keep warm for 20 minutes, discharge while hot, and cool to prepare hot-melt pressure-sensitive adhesive.

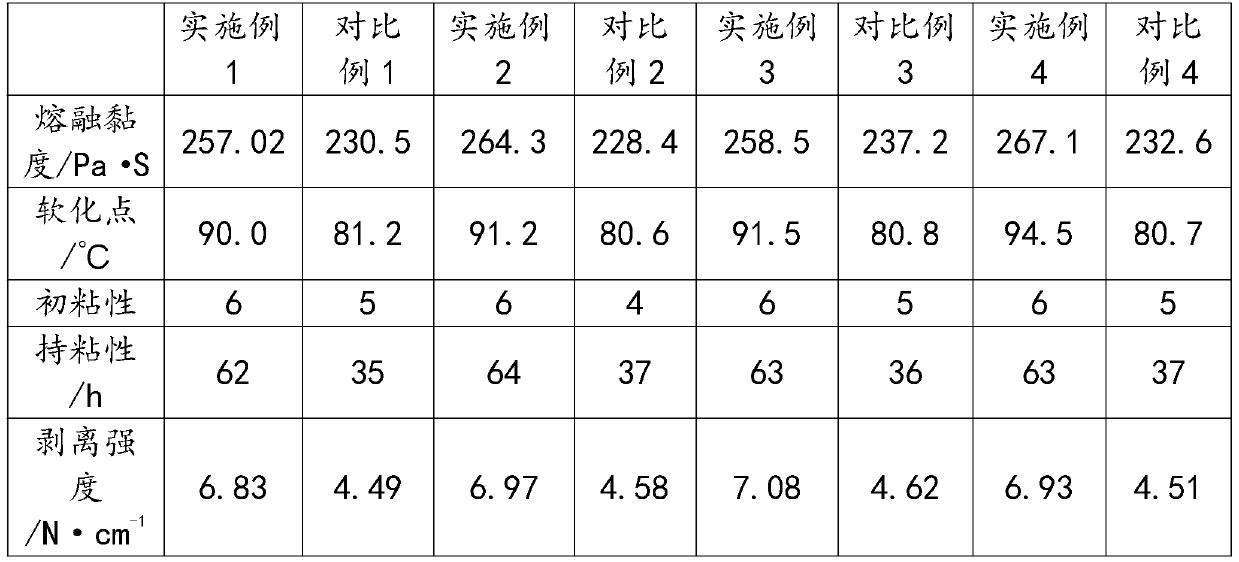

Embodiment 1

[0064] Environmentally friendly hot-melt pressure-sensitive adhesive, made of the following raw materials in parts by weight: 25 parts of styrene-butadiene-styrene, 28 parts of modified petroleum resin, 6 parts of rosin resin, 12 parts of plasticizer, modified filler 2 parts, 0.2 parts of silane coupling agent, 0.2 parts of 2,6-di-tert-butyl-p-cresol;

[0065] The plasticizer is a composition composed of liquid paraffin and dibutyl phthalate in a mass ratio of 2:1.

Embodiment 2

[0069] The environment-friendly hot-melt pressure-sensitive adhesive is made of the following raw materials in parts by weight: 28 parts of styrene-isoprene-styrene, 31 parts of modified petroleum resin, 7.5 parts of terpene resin, 15 parts of plasticizer, modified 2.3 parts of permanent filler, 0.24 parts of silane coupling agent, 0.23 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester;

[0070] The plasticizer is a composition composed of liquid paraffin and dibutyl phthalate in a mass ratio of 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| stay sticky | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com