Ultraviolet-curing hot-melt pressure-sensitive adhesive high in peeling strength, and preparation method and applications thereof

A heat-curing and high-peeling technology, which is applied in the direction of pressure-sensitive films/sheets, non-polymer organic compound adhesives, adhesives, etc., can solve the problem of poor UV resistance of hot-melt pressure-sensitive adhesives that cannot meet the waterproof requirements of exposed roofs and other problems, to increase the adjustment space and convenience, improve the fitting effect, enhance the compatibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

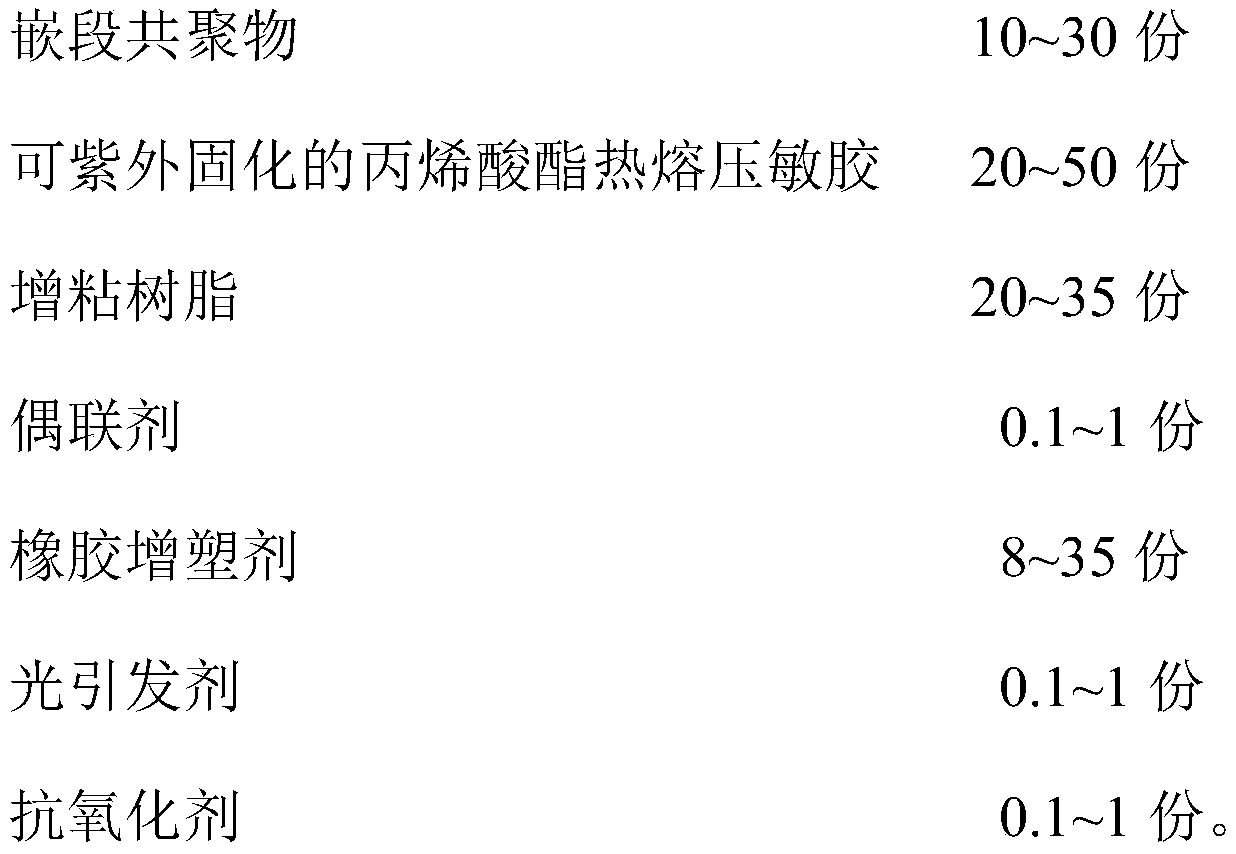

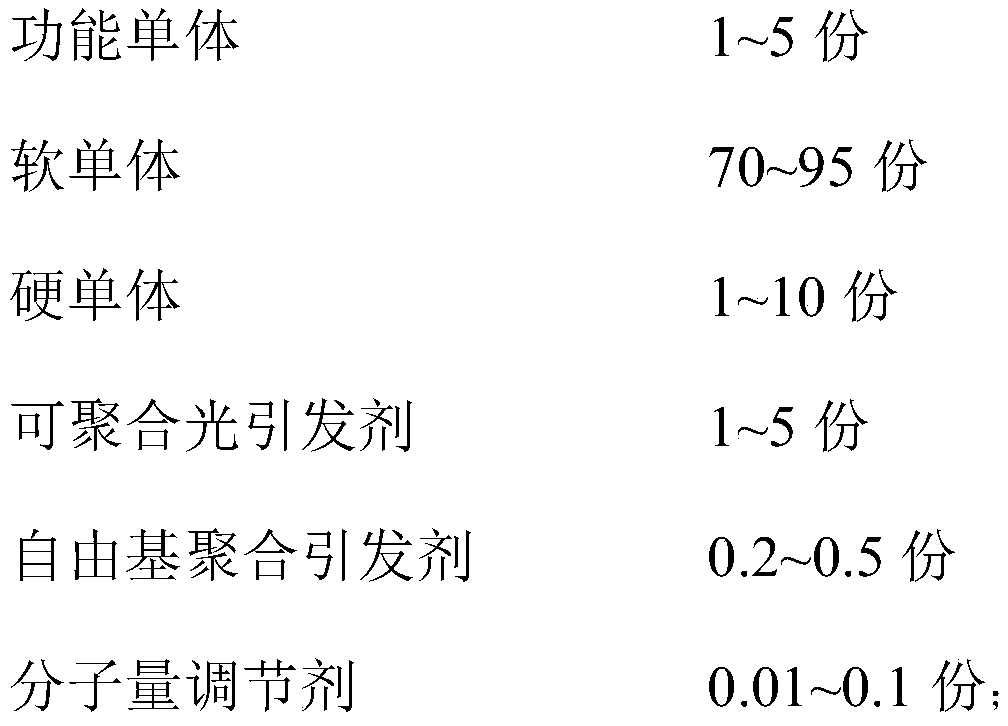

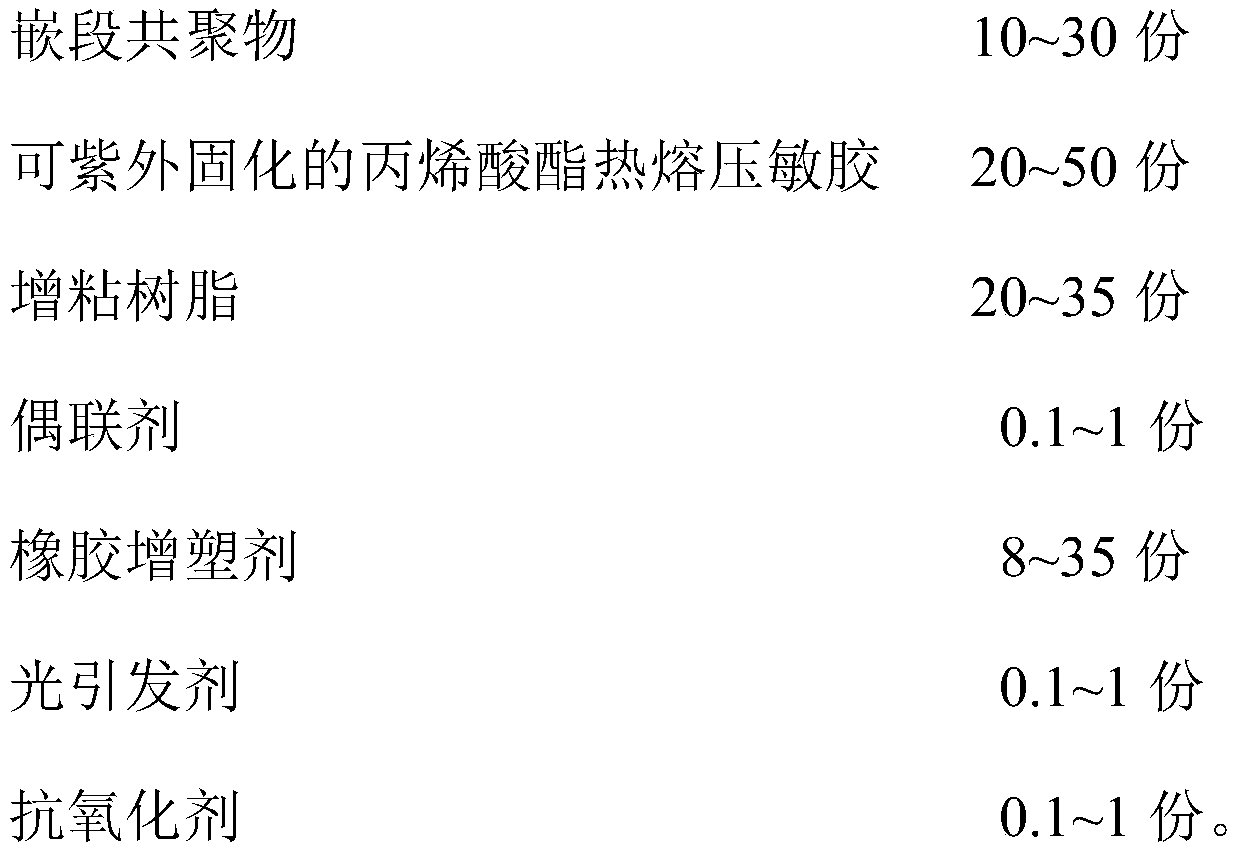

Method used

Image

Examples

Embodiment 1

[0068] Add 0.1 parts by weight of 3-(triethoxysilyl)propyl methacrylate into 15 parts of naphthenic oil KN4010, stir and disperse in a kneader, then add 20 parts of styrene with a content of 15%, Diblock content is 20% styrene-isoprene-styrene SIS elastomer, 30 parts of carbon five petroleum resins, 35 parts of acrylate hot-melt pressure-sensitive adhesive (wherein, acrylate hot-melt pressure-sensitive adhesive consists of 2 Parts of hydroxyethyl acrylate, 90 parts of butyl acrylate, 3 parts of vinyl acetate, 5 parts of ABP, 0.3 parts of azobisisobutyronitrile and 0.05 parts of dodecyl mercaptan), 0.2 parts of 2 , 4,6 (trimethylbenzoyl) diphenyl phosphine oxide, 0.2 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate are fully kneaded evenly, After heating, stirring, vacuuming and defoaming under the condition of nitrogen protection, a UV-curable hot-melt pressure-sensitive adhesive with high peel strength is obtained.

Embodiment 2

[0070] Add 0.2 parts by weight of cetyltrimethoxysilane to 20 parts of naphthenic oil KN4010, stir and disperse in a kneader, then add 20 parts of styrene content of 20% and diblock content of 20% Styrene-isoprene-styrene SIS elastomer, 30 parts of C5 petroleum resin, 30 parts of acrylate hot-melt pressure-sensitive adhesive (wherein, acrylate hot-melt pressure-sensitive adhesive consists of 4 parts of hydroxyethyl methacrylate, 85 parts of cinnamyl acrylate, 8 parts of methyl methacrylate, 3 parts of ABBP, 0.3 parts of azobisisobutyronitrile and 0.04 parts of dodecyl mercaptan), 0.3 parts of 2,4,6 (Trimethylbenzoyl) diphenylphosphine oxide, 0.3 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate were fully kneaded evenly, under the condition of nitrogen protection After heating, stirring and vacuuming for defoaming, a high peel strength UV-curable hot-melt pressure-sensitive adhesive is obtained.

Embodiment 3

[0072] Add 0.3 parts by weight of cetyltrimethoxysilane to 20 parts of naphthenic oil KN4010, stir and disperse in a kneader, and then add 15 parts of benzene with a styrene content of 30% and a diblock content of 40%. Ethylene-isoprene-styrene SIS elastomer, 30 parts of C5 petroleum resin, 35 parts of acrylate hot-melt pressure-sensitive adhesive (among them, acrylate hot-melt pressure-sensitive adhesive consists of 2 parts of hydroxyethyl acrylate, 1 part of horse Anhydride, 20 parts of ethyl acrylate, 30 parts of butyl acrylate, 35 parts of cinnamyl methacrylate, 4 parts of methyl methacrylate, 1 part of AHBP, 0.3 parts of azobisisobutyronitrile and 0.1 parts of prepared from dialkyl mercaptan), 0.3 part tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.5 part β-(3,5-di-tert-butyl N-octadecyl-4-hydroxyphenyl)propionate was fully kneaded evenly, and after heating, stirring and vacuuming and defoaming under the condition of nitrogen protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com