High solid coating for container and preparation method of high solid coating

A high solid content, container technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of wear resistance, high temperature and high humidity resistance, dry film thickness and drying speed that cannot meet the performance requirements of container special coatings, Increase equipment cost and energy consumption, slow coating film drying speed and other issues, achieve good gloss and color retention, improve coating line efficiency, and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The high-solid coating for containers and the preparation method thereof, and the operation steps of the method are as follows:

[0041] (1) Preparation of main agent:

[0042] Based on the total mass of high-solids and low-viscosity hydroxy acrylic resin, first add 20-40% of high-solids and low-viscosity hydroxy acrylic resin, and slowly add 1-10% of active diluent, 1 to 5% of rheology additives, Wetting and dispersing agent 1~3%, leveling agent 0.1~0.5% and defoaming agent 0~1%, after dispersing at high speed to a uniform viscous slurry liquid, add functional pigment 1~10% and light fast pigment 20 ~25%, evenly dispersed, grind to a fineness of less than 20μm, then add the remaining high-solids low-viscosity hydroxy acrylic resin, leveling agent two 0.1-0.5%, add 1-5% mixed solvent to adjust the viscosity to pass, filter Packaging is the main agent;

[0043] (2) Preparation of curing agent:

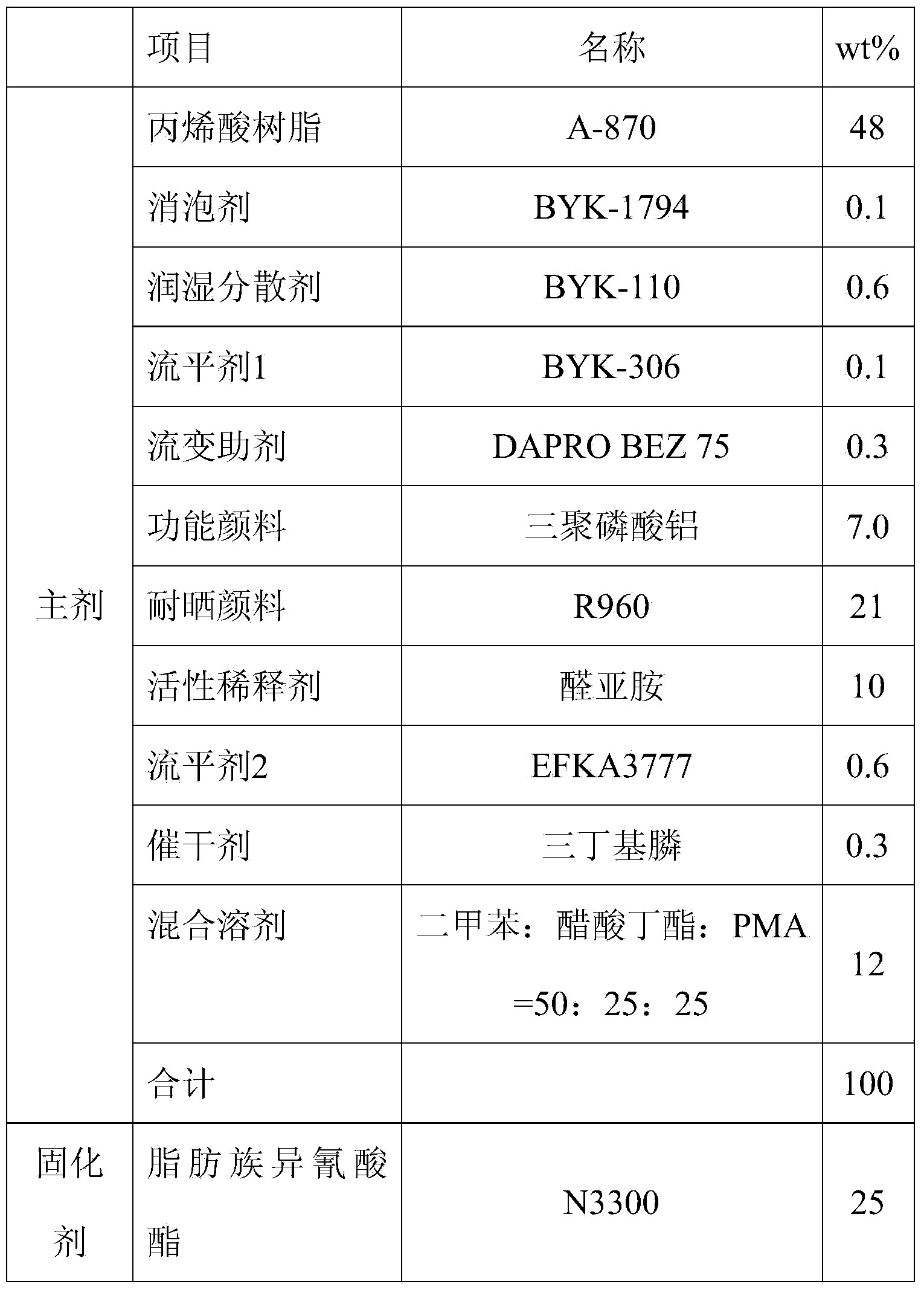

[0044] Select one or two of high solid aliphatic isocyanate N3390, N3300 or HT100....

Embodiment 1

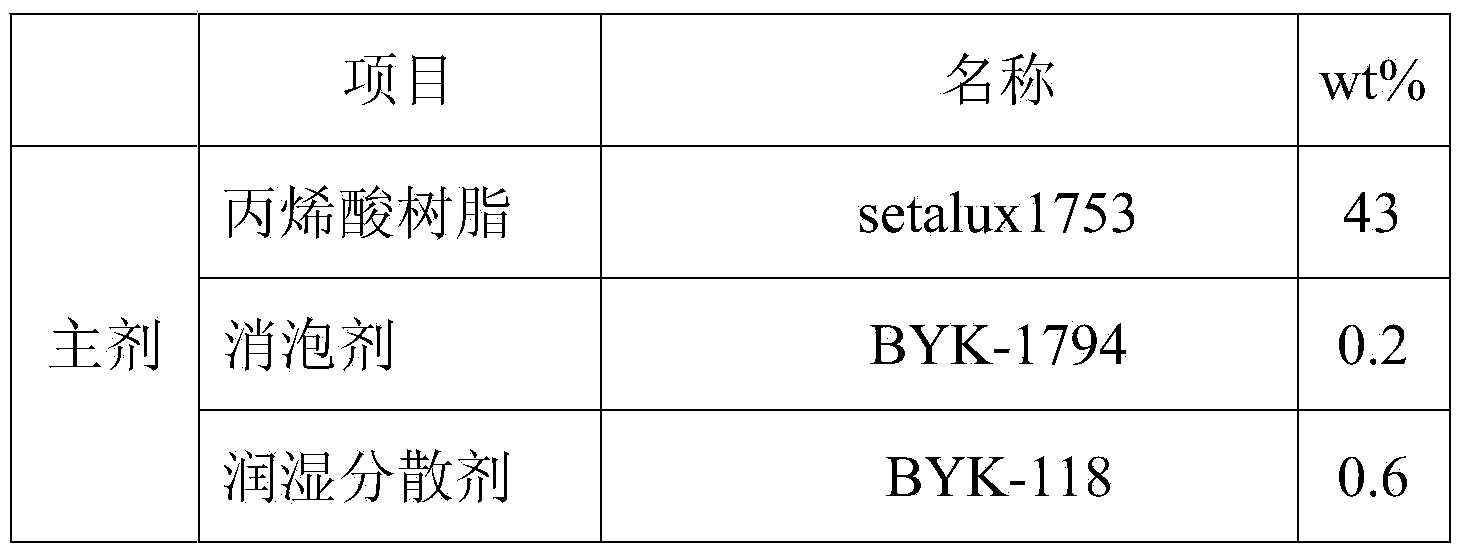

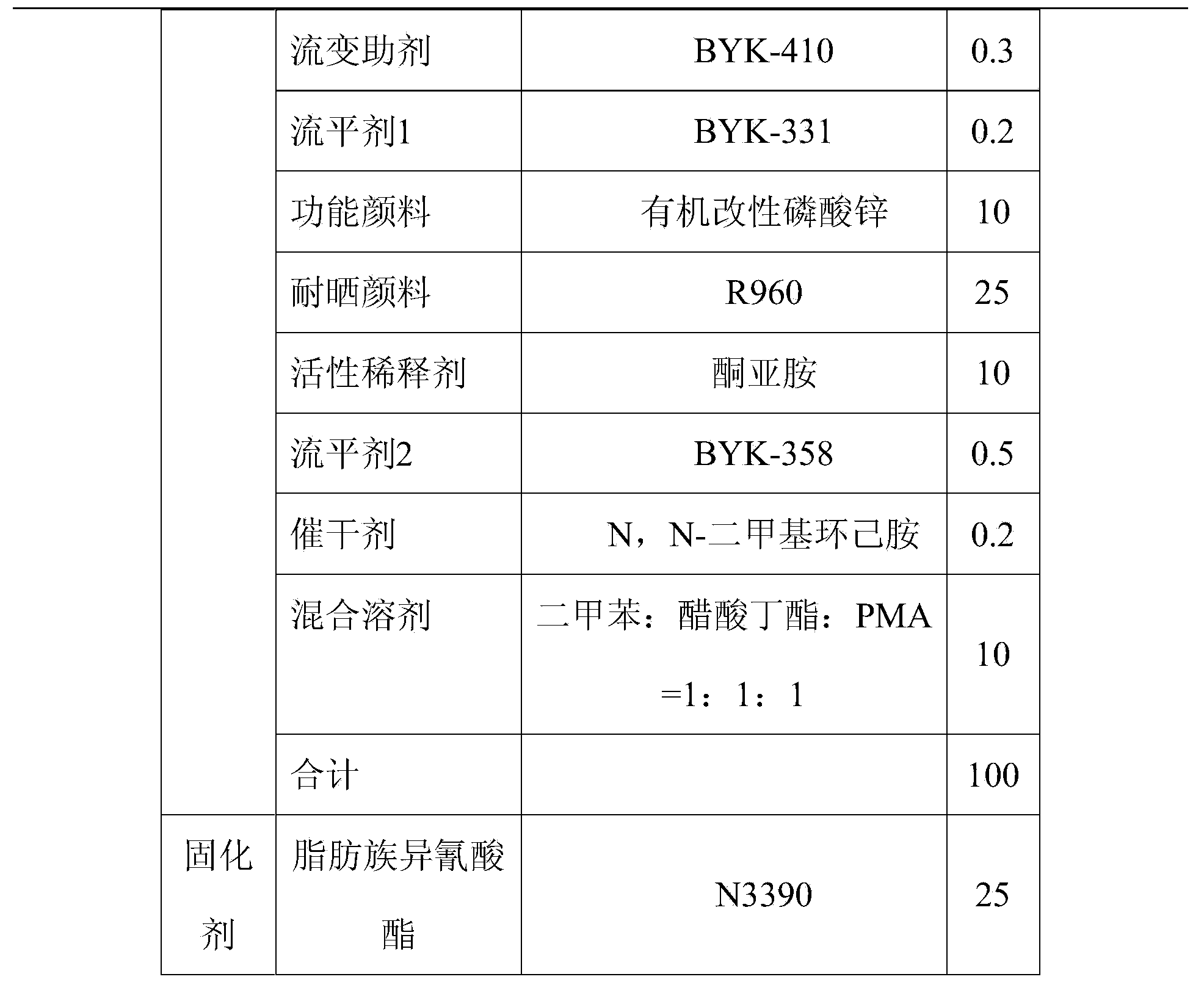

[0047] The main agent formula of the present invention is shown in Table 1:

[0048] Table 1 Example 1 formula

[0049]

[0050]

Embodiment 1

[0051] The preparation method of the coating of the present invention in Example 1 is as follows:

[0052] (1) Preparation of the main agent: based on the total mass of the hydroxy acrylic resin, first add 20% of the hydroxy acrylic resin setalux 1753, and slowly add the active diluent ketimine, wetting and dispersing agent BYK-118, BYK-331, After BYK-410 and defoamer BYK-1794 are dispersed at high speed to a uniform viscous slurry liquid, add functional pigment organically modified zinc phosphate and light fast pigment titanium dioxide R960, disperse uniformly and grind to a fineness of less than 20μm, then Add the remaining hydroxy acrylic resin, BYK-358 and N,N-dimethylcyclohexylamine according to the formula amount, adjust the viscosity with a mixed solvent to pass, and filter and package as the main agent;

[0053] (2) Pack the curing agent according to the specifications, in this example it is Bayer HDI trimer N3390;

[0054] (3) According to the mass ratio of the main agent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com