Highly durable super-hydrophilic coating

A super-hydrophilic and durable technology, used in coatings, alkali metal silicate coatings, etc., can solve the problems of inability to use for a long time, difficult to achieve complete hydrolysis, and reduce the adhesion of materials, so as to improve the bonding of materials. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation of alcohol-based superhydrophilic silicone coatings. Preparation of silica sol. Silicic acid esters are added to a solvent (for example, an alcohol solvent), and after being uniformly stirred, an acidic catalyst and deionized water are added dropwise thereto, and stirred for 3 to 5 hours to obtain a silica sol. The mass concentration of the silica sol formed by the acid-catalyzed hydrolysis of the silicate can be 1-20%. The mass ratio of the alcohol solvent, silicate, acidic catalyst, and deionized water may be (60-98):(1-20):(0-2):(1-20). The alcohol solvent may be one or more of methanol, ethanol, isopropanol and isobutanol. The acid catalyst can be one or more of formic acid, acetic acid, hydrochloric acid, nitric acid, sulfuric acid and phosphoric acid. The silicate can be one or more than ethyl orthosilicate, methyl orthosilicate and the like. The silica nanoparticles are uniformly dispersed in a solvent (for example, an alcohol solvent, etc.), and ...

Embodiment 1

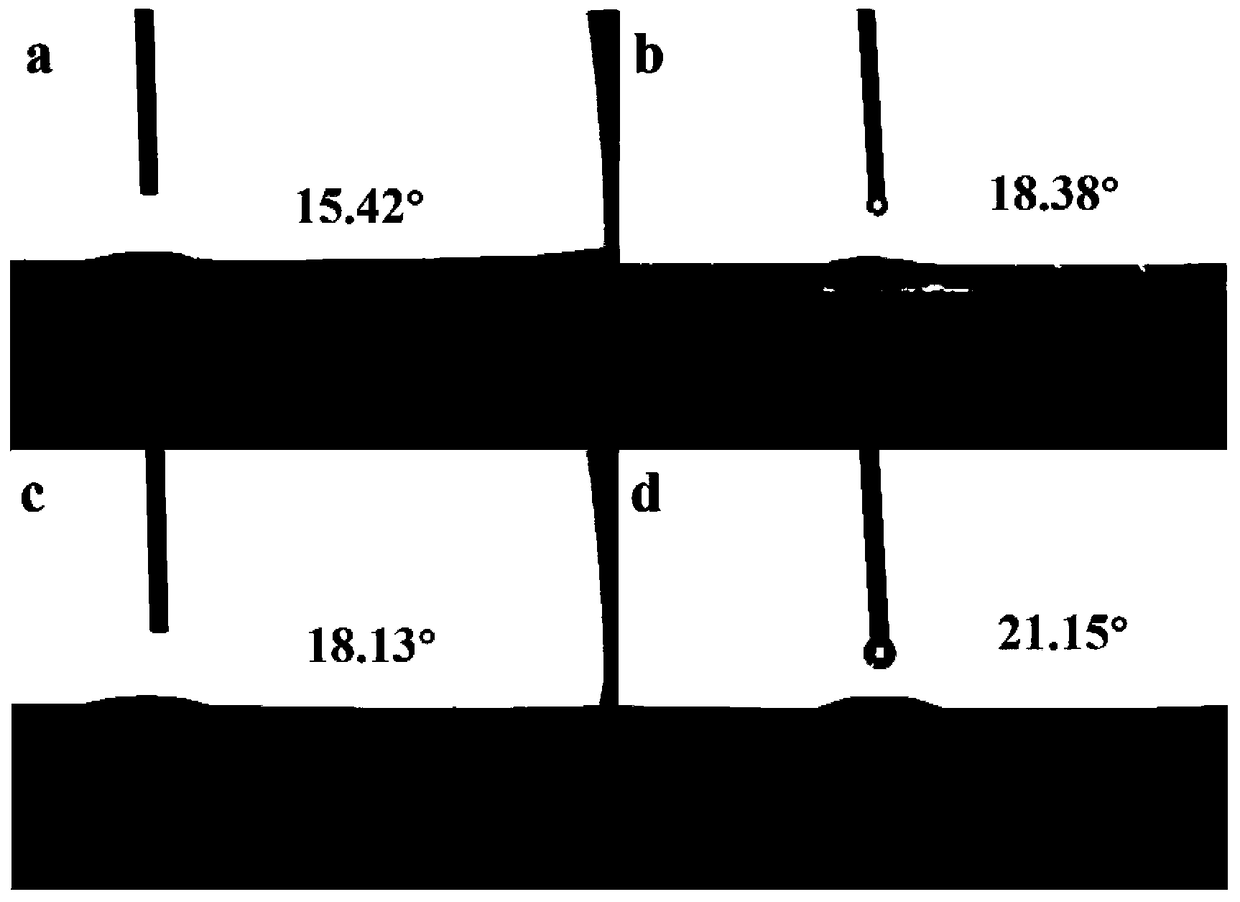

[0039] A high-durability super-hydrophilic coating: the method of the present invention uses a sol-gel process to prepare a super-hydrophilic film by scraping. Clean the surface of ordinary glass with alcohol and use it as the coating substrate. Use orthoethyl silicate (TEOS) as the silicon source, HCl as the catalyst, and ethanol as the solvent, configure a silica sol with a concentration of about 4%, and mix it with an ethanol dispersion of silicon oxide with a concentration of 4%, according to a mass ratio of 1: 1 Mix evenly to obtain the underlying alcoholic super-hydrophilic silicone coating; prepare 4% sodium water glass as the top coat. Use the scraper coating method to evenly coat the bottom super-hydrophilic silicone coating on the cleaned glass surface. After curing for 30 minutes at 20°C, apply the prepared surface water glass coating on the surface with the scraper coating method. Curing for 30min. figure 1 The wettability of alcoholic superhydrophilic coatings a...

Embodiment 2

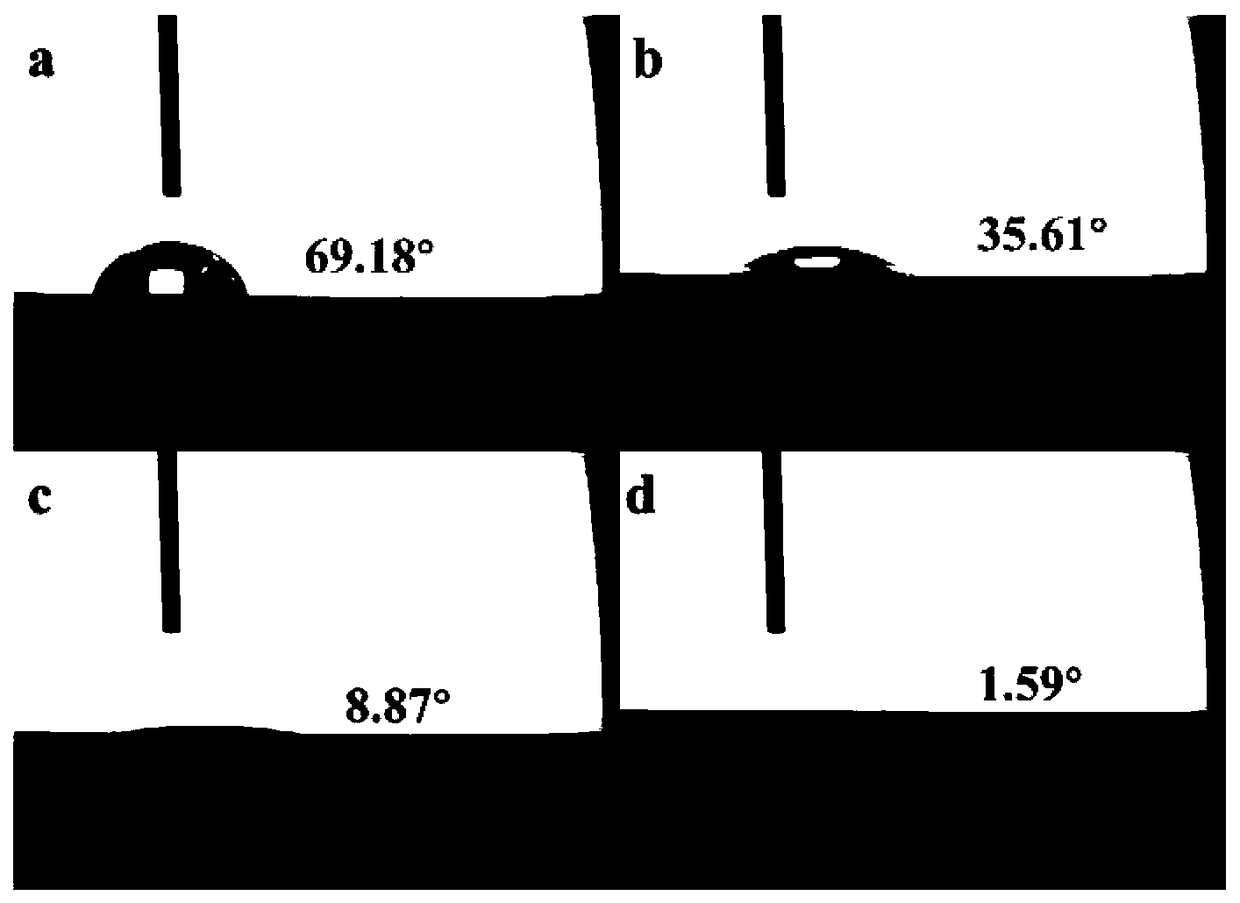

[0044] A high-durability super-hydrophilic coating: the method of the present invention uses a sol-gel process to prepare a super-hydrophilic film by scraping. Clean the surface of ordinary glass with alcohol and use it as the coating substrate. Use orthoethyl silicate (TEOS) as the silicon source, HCl as the catalyst, and ethanol as the solvent, configure a silica sol with a concentration of about 4%, and mix it with an ethanol dispersion of silicon oxide with a concentration of 2%, according to a mass ratio of 1: 1 Mix evenly to obtain the underlying alcoholic super-hydrophilic silicone coating; prepare sodium water glass with a concentration of 20% as the top coat. Use the scraper coating method to evenly coat the bottom super-hydrophilic silicone coating on the cleaned glass surface. After curing for 30 minutes at 20°C, apply the prepared surface water glass coating on the surface with the scraper coating method. Curing for 30min. In the high-durability super-hydrophilic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com