PU matte white finish paint and preparation method thereof

A white topcoat, matte technology, applied in coatings, polyurea/polyurethane coatings, fireproof coatings, etc., can solve the problems of low hardness of the paint film, low temperature resistance, poor water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the anti-settling slurry includes the following steps: select a clean and standard dispersing tank, put polyamide wax and xylene 2 in sequence, start the dispersing machine, and disperse for 15-20 minutes at 600-800 rpm.

[0049] The present invention has no special limitation on the types of the polyamide wax and xylene 2.

[0050] The n-butyl acetate 1 and propylene glycol methyl ether acetate 1 can adjust the viscosity of the paint and the fluidity and penetration of the film. The mass percent of the n-butyl acetate 1 is 1% to 3%, preferably 1% to 2%, more preferably 1.8%; the mass percent of the propylene glycol methyl ether acetate 1 is 0.5% to 3%, preferably 0.8% to 2%, more preferably 1%. The present invention has no special restrictions on the models of the n-butyl acetate 1 and propylene glycol methyl ether acetate 1.

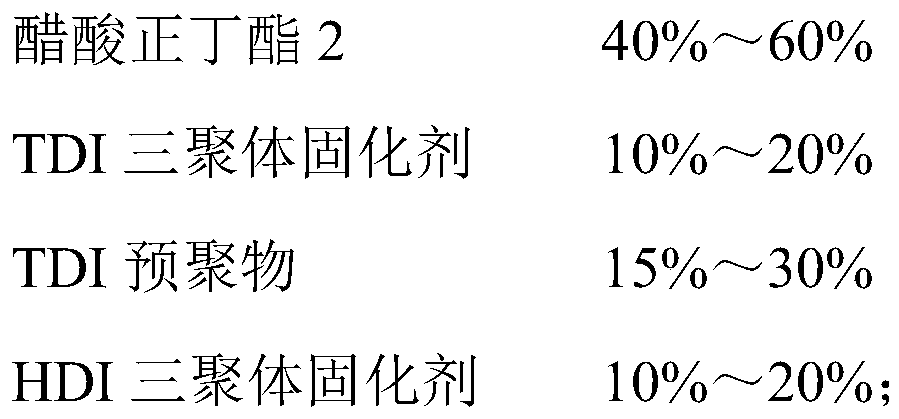

[0051] The raw material of component B in the present invention includes n-butyl acetate 2 with a mass percentage o...

Embodiment 1

[0066] This embodiment provides a kind of PU matte white topcoat, which is prepared by components A, B and C in a mass ratio of 1:0.5:0.5:

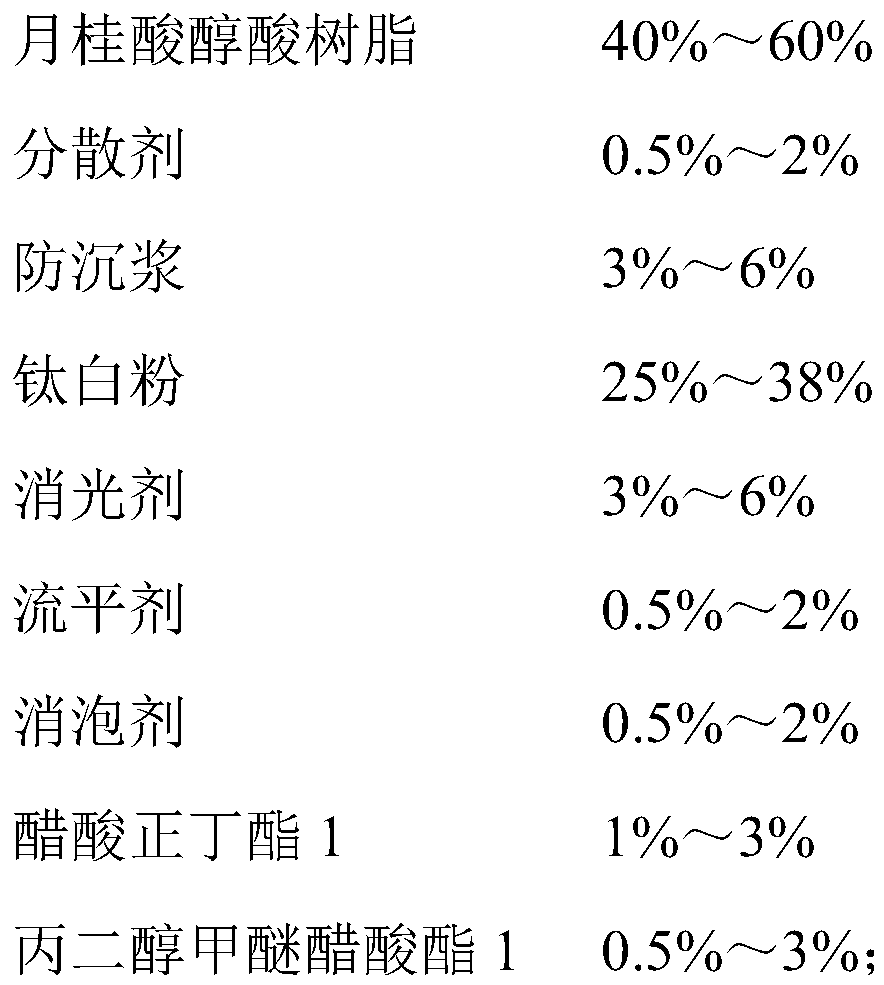

[0067] The raw material of A component is made up of the component of following weight percent:

[0068]

[0069] The viscosity of H32-70J lauric alkyd resin is 12S~15S, the hydroxyl value is 110mgKOH / g~130mgKOH / g, and the acid value is 10mgKOH / g~12mgKOH / g.

[0070] The preparation method of component A is as follows: select a clean dispersion cylinder that meets the standards, put in H32-70J lauric alkyd resin, dispersant, and anti-sedimentation agent in sequence, start the disperser, and disperse at a low speed of 300-500 rpm 5 to 10 minutes; then add rutile titanium dioxide, matting agent, leveling agent, defoamer, n-butyl acetate 1 in turn under stirring, and disperse at 800 to 1200 rpm for 10 to 20 minutes at high speed until the fineness ≤30um; finally add propylene glycol methyl ether acetate 1 to adjust the viscosity to: 8500m...

Embodiment 2

[0084] This embodiment provides a kind of PU matte white topcoat, which is prepared by components A, B and C in a mass ratio of 1:0.5:0.5:

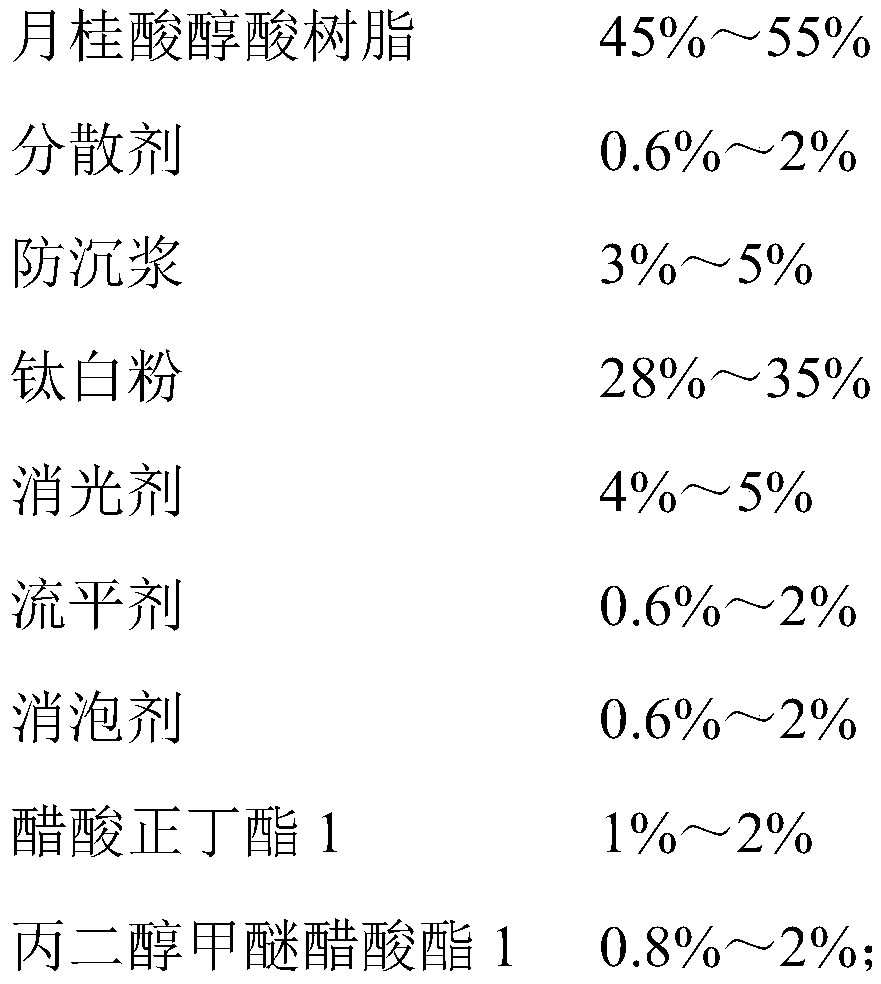

[0085] The raw material of A component is made up of the component of following weight percent:

[0086]

[0087] The viscosity of H32-70J lauric alkyd resin is 12S~15S, the hydroxyl value is 110mgKOH / g~130mgKOH / g, and the acid value is 10mgKOH / g~12mgKOH / g.

[0088] The preparation method of component A is as follows: select a clean dispersion cylinder that meets the standards, put in H32-70J lauric alkyd resin, dispersant, and anti-sedimentation agent in sequence, start the disperser, and disperse at a low speed of 300-500 rpm 5 to 10 minutes; then add rutile titanium dioxide, matting agent, leveling agent, defoamer, n-butyl acetate 1 in turn under stirring, and disperse at 800 to 1200 rpm for 10 to 20 minutes at high speed until the fineness ≤30um; finally add propylene glycol methyl ether acetate 1 to adjust the viscosity to: 8500m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com