Dealcoholized room temperature vulcanized silicone rubber sealant and preparation method thereof

A room temperature vulcanization and sealant technology, applied in adhesives and other directions, can solve the problems of high temperature and high humidity resistance and poor storage performance, and achieve the effect of improving storage performance, simple preparation process and eliminating process problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

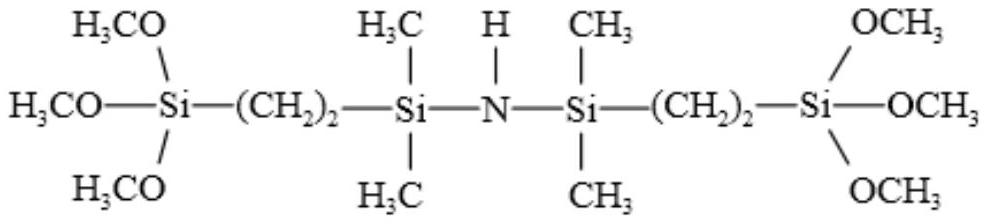

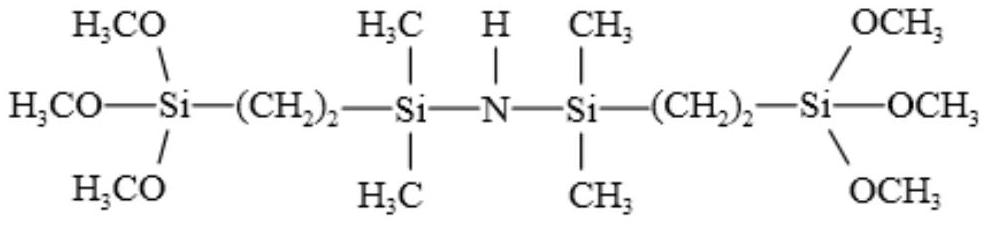

Image

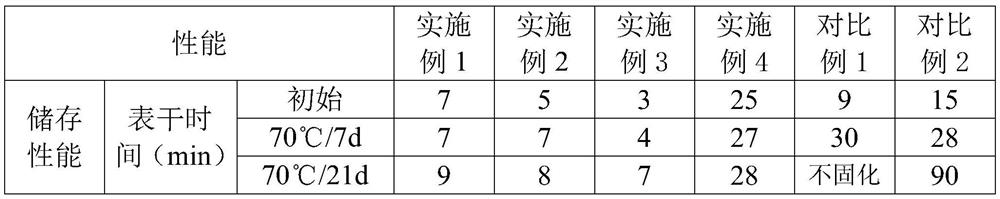

Examples

Embodiment 1

[0035] Select α, ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mpa.s and simethicone oil with a viscosity of 100mpa.s. The component ratios are as follows:

[0036] A. α, ω-Dihydroxypolydimethylsiloxane 100 parts

[0037] B. 1.3 parts of capping agent

[0038] C. 0.03 parts of trifluoromethanesulfonic acid

[0039] D. 15 parts of simethicone oil

[0040] E. Calcium carbonate 120 parts

[0041] F. 4.5 parts of methyltrimethoxysilane

[0042] G. 2 parts of γ-aminopropyltriethoxysilane

[0043] H. 3 parts of bis(ethyl acetoacetate) diisopropyl titanate

[0044] Pass N 2 Add the A, B, and C components of the above viscosity and parts into the reaction kettle under protection, stir at room temperature for 15 minutes, and then stir for 10 minutes under the vacuum condition of -0.09~-0.1MPa to remove small molecules, and then add D and E components , Stir for 30 minutes under vacuum condition of -0.09~-0.1MPa, after mixing evenly, add components F, G and H in seque...

Embodiment 2

[0046] Choose α, ω-dihydroxypolydimethylsiloxane with a viscosity of 6000mpa.s and simethicone oil with a viscosity of 500mpa.s. The component ratios are as follows:

[0047] A. α, ω-Dihydroxypolydimethylsiloxane 100 parts

[0048] B. 1.8 parts of capping agent

[0049] C. 0.05 parts of trifluoromethanesulfonic acid

[0050] D. 10 parts of simethicone oil

[0051] E. 100 parts of calcium carbonate, 12 parts of fumed white carbon black

[0052] F. Vinyltrimethoxysilane 4 parts

[0053] G. 0.8 parts of γ-aminoethylaminopropyltrimethoxysilane

[0054] H. Tetraisopropyl titanate 0.8 parts

[0055] Pass N 2 Add the A, B, and C components of the above viscosity and parts into the reaction kettle under protection, stir at room temperature for 18 minutes, then stir for 10 minutes under the vacuum condition of -0.09~-0.1MPa to remove small molecules, and add D and E components , Stir for 30 minutes under vacuum condition of -0.09~-0.1MPa, after mixing evenly, add components F, G a...

Embodiment 3

[0057] The main difference from Example 1 is that the proportion of components is different.

[0058] A. α, ω-Dihydroxypolydimethylsiloxane 100 parts

[0059] B. 0.5 parts of capping agent

[0060] C. 0.1 parts of trifluoromethanesulfonic acid

[0061] D. 10 parts of simethicone oil

[0062] E. Calcium carbonate 100 parts

[0063] F. 3 parts of methyltrimethoxysilane

[0064] G. 0.5 parts of γ-aminopropyltriethoxysilane

[0065] H. 5 parts of bis(ethyl acetoacetate) diisopropyl titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com